09-26/2025

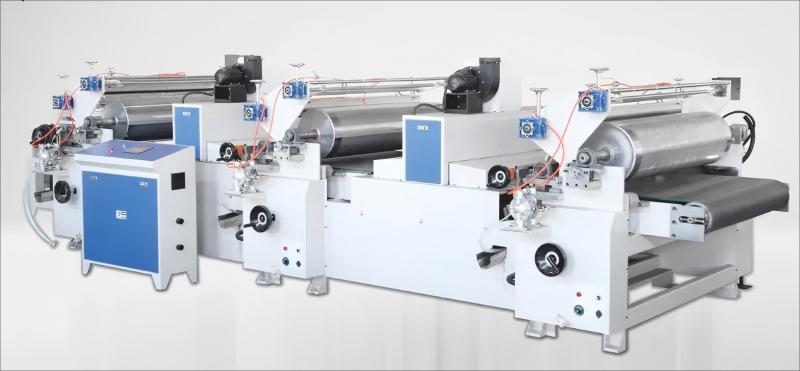

For example, when processing large quantities of standard, flat panels, roller coating machines are superior; when handling complex furniture components, automatic spraying machines are more adaptable.