Common inks for wood grain printing machines include solvent-based gravure decorative inks, water-based gravure decorative inks, UV-curable gravure/flexographic inks, digital UV inkjet inks, and, in specific applications, thick film auxiliary inks for screen printing and specialized thermal transfer inks.

The final selection must be based on a comprehensive evaluation of five key factors: substrate type (MDF/plywood/PVC/aluminum coil, etc.), curing method (hot air/IR/UV), color rendering (two-color/multi-color/gradient), line speed and equipment (wood grain printing machine structure and width), and environmental and safety considerations (VOCs/ozone/flammability).

The following will explain the ink system, composition mechanism, parameter window, process matching, quality control, and common troubleshooting related to wood grain printing machines, ensuring that you can use them accurately and reliably after reading this.

What color formation principles are typically used with wood grain printing machines?

What are the main categories of inks used for these machines?

In terms of process principles and equipment structure, wood grain printing machines primarily utilize gravure roller printing, although flexographic/anilox roller metering transfer and digital inkjet direct printing are also available. The corresponding ink categories are as follows:

1. Solvent-based gravure decorative inks

Use organic solvents such as alcohols, esters, and ketones as carriers, resins as the primary film-forming agent, and hot air/IR drying.

• Features: Stable inking, rapid drying, and strong adaptability, suitable for large-scale two-color/multi-color continuous wood grain printing.

• Concerns: VOC emissions, explosion prevention, fire prevention, and workshop ventilation.

2. Water-based gravure decorative inks

Use water as the primary solvent, supplemented with a small amount of alcohol/ether as a co-solvent, and the resin is either an emulsion or water-soluble.

• Features: Environmentally friendly and low odor.

• Concerns: Requires higher substrate surface energy and drying capacity, resulting in a narrower window than solvent-based inks.

3. UV-curable gravure/flexographic inks (free radical/cationic)

Use UV-initiated polymerization, cures in seconds, and is low in VOC.

• Features: High line speed, small footprint, instant curing;

• Focus: Spectrum matching with initiator (LED 385/395/405 nm or broad-spectrum mercury lamp), pigment shading resulting in "touch-drying" (not inside-drying), UV safety and ozone (mercury lamp).

4. Digital UV Inkjet Ink

Compatible with piezoelectric printheads (such as grayscale printheads), UV curing.

• Features: Plate-free, flexible colors, variable data;

• Focus: Viscosity/sheet size matching with printheads, color management with RIP, and curing synchronization.

5. Screen-Assisted Ink

Used for overlaying localized nodules, pearlescent, and relief effects, compatible with primary printing (gravure/inkjet).

• Features: Thick ink layer, strong tactile feel;

• Focus: Matching the tempo with the overall line volume, and compatibility with subsequent overprinting/curing.

6. Thermal Transfer/Transfer Ink

For use on transfer film/paper, then transferred to the substrate using heat and pressure.

• Features: Suitable for wrapping profiles or special-shaped parts;

• Focus: Compatibility with adhesive systems, heat resistance, and migration control.

How to choose the ink system for different substrates (MDF, plywood, PVC, metal)?

—What you print on determines what you use!

1. MDF/Particleboard/Plywood (Mainly Flat Panels)

• Common Processing Route: Primer sealer → Sanding → Wood Grain Printing Machine two-color gravure → Hot air/UV curing → Overprint/wear-resistant layer → Curing.

• Ink Priority: Solvent-based gravure or UV gravure; water-based inks require stronger drying and primer properties.

• Key: Porosity and moisture content control, primer compatibility, post-print adhesion, and chemical resistance.

2. Plastic Sheets or Coils, Such as PVC/PP/ABS

• Polarity and surface energy must be considered; corona/plasma treatment may be required if necessary.

• Ink: Solvent-based gravure or UV-curable; PP requires a dedicated adhesive system.

• Key considerations: Swelling and stress cracking, migration resistance, and scratch resistance.

3. Aluminum/Steel Coil Lamination and Coated Metal Sheet

• Commonly used for roll-to-roll high-speed printing, with high requirements for weather resistance and adhesion.

• Ink: Solvent-based high-temperature baking or UV-curable system, matched with a metal primer/pre-coat.

• Key considerations: Metal pretreatment, impact/bending resistance, and post-forming adaptability.

4. Thermal Transfer to Profiles/Shaped Parts

• First, print the wood grain on the transfer film, then thermally transfer to the substrate.

• Ink: Specialized thermal transfer ink, used in conjunction with an adhesive/primer.

What are the components of ink?

How do these components affect printability and usability?

The typical composition of decorative inks includes film-forming resins, pigments/dyes, solvents or reactive diluents, additives, and photoinitiators (for UV applications):

• Film-forming resins (acrylic, polyurethane, alcohol-soluble resins, epoxy/cationic systems, etc.): Determine adhesion, hardness, flexibility, and chemical resistance.

• Pigments/dyes: Provide hue and hiding; wood grain often uses a combination of inorganic black/brown and organic yellow/red to achieve both transparency and texture sharpness.

• Solvents/reactive diluents: Affect viscosity, evaporation/curing rate, and application window; in UV applications, reactive diluents contribute to film formation.

• Additives (leveling, defoaming, wetting, anti-cratering, adhesion promoters): Directly impact flawless appearance and overprint stability.

• Photoinitiators (for UV systems): Spectral matching is key; LEDs typically use products with an absorption peak between 385–405 nm, while mercury lamps can be used with complex initiators.

How to match colors for two-color wood grain printing?

The classic division of labor for a two-color printing machine is a "dark main texture layer" + a "light base/auxiliary texture layer":

• Dark ink: Sharp lines, fine mesh, and slightly higher viscosity to inhibit lateral flow; ensuring clear boundaries between growth rings and scars.

• Light ink: Focuses on spreading and smoothness, enhancing layering and fullness; slightly lower viscosity and good wettability to avoid "floating" or jagged edges with darker colors.

• ΔE and coverage: Maintaining a minimum coating weight while maintaining color hue facilitates long-term stability in drying/curing and overprint accuracy.

• Primer color: Micron-level base color can significantly impact the final appearance; the lightness and color temperature of the primer must be synergistic with the two-color ink.

What are the specific pitfalls of UV inks?

How can they be avoided when used on wood grain printing machines?

There are three key factors that contribute to UV's high efficiency:

• Spectral matching: LEDs (385/395/405 nm) require corresponding initiators; mercury lamps, while broad-spectrum, carry the risk of heat, ozone, and short-wave yellowing.

• Light blocking and thick coating: Dark or highly filled inks can block UV light, leading to overcure on the surface and undercure on the bottom. Apply thin layers multiple times or adjust the formulation.

• Safety and environmental protection: Light-shielding chambers, door interlocks, and safety goggles are recommended; mercury lamps should be equipped with exhaust and ozone treatment, and waste lamps should be managed as hazardous waste; for LEDs, pay attention to heat dissipation and electrical safety.

• Optimization strategy: Determine the target dose (mJ/cm²) and monitor it online with a radiometer; maintain a stable cure through segmented energy, multiple lamp positions, and closed-loop line speed control; for dark patterns, apply a light-to-dark coating first or use a co-initiator to enhance deep-dark reactions.

"What inks should the Wood Grain Printing Machine use?"

On wood grain mass production lines centered around two-color/multi-color gravure, solvent-based decorative gravure inks and UV-curable gravure/flexographic inks are the mainstays. Where environmental pressures are higher or design flexibility is required, water-based gravure inks and digital UV inkjet inks are effective supplements.

1. Selection Logic

We carefully consider the five key factors: substrate, curing, design, line speed, and environmental/safety. This is further refined within parameter windows such as viscosity/surface tension, cell density/ink loading, and drying/UV dosage. Quality is then locked in a closed loop using line inspections for ΔE, adhesion, chemical resistance, and appearance.

2. Key to Implementation

We ensure that the mechanical capabilities of the Wood Grain Printing Machine (servo overprinting, line speed, and width) are truly matched to the ink formulation, primer/topcoat system, and drying/curing capabilities. With accurate window settings and SOPs in place, ink selection is not a spur-of-the-moment decision, but a verifiable, replicable, and traceable engineering decision.

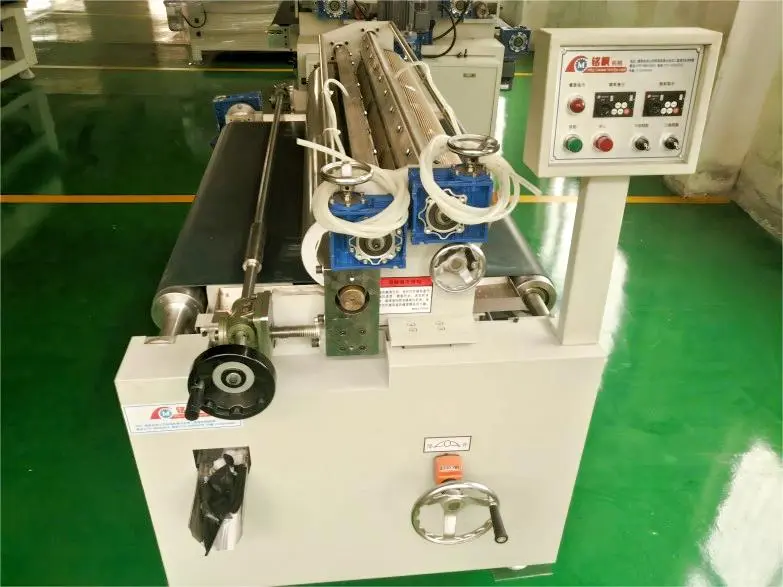

Where can I buy XMF Machinery coating machines?

You can purchase our surface coating machines directly from our company’s official website or contact our sales team for wholesale and retail purchasing. We supply our high-quality coating and printing machinery globally, including Southeast Asia, the Middle East, and Africa. We offer competitive prices and regular discounts, making it easier for buyers to invest in efficient, affordable coating equipment.