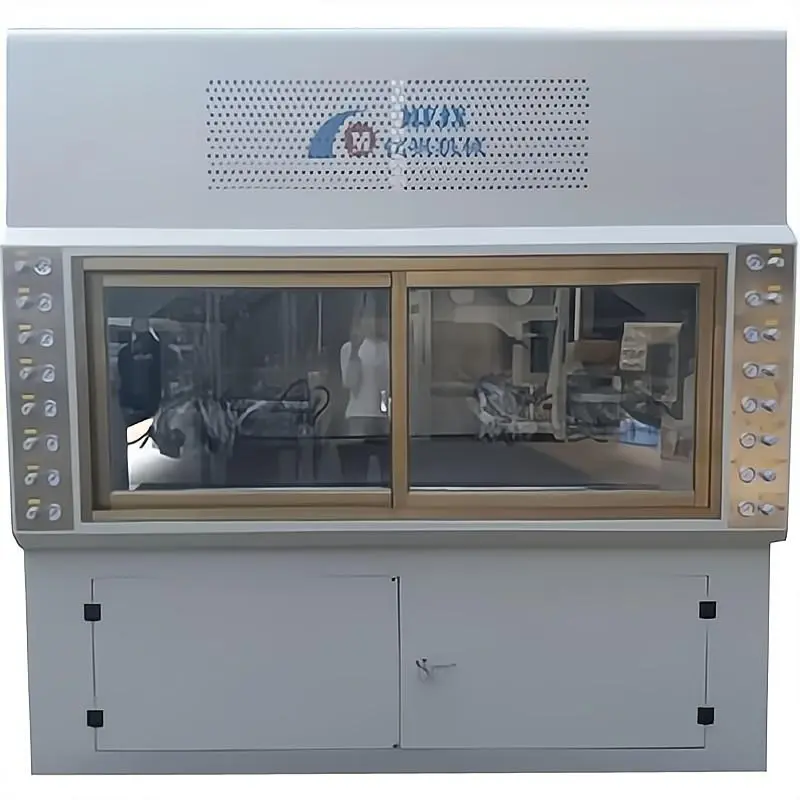

Automated spraying machines have become a mainstream surface treatment equipment in modern wood products industries, including furniture manufacturing, interior decoration, door panel production, and flooring. They use automated, CNC-controlled methods to evenly apply paint to wood surfaces, simultaneously improving efficiency and quality.

During the entire spraying process, many manufacturers often question a key process step: Is primer necessary before painting wood?

This seemingly simple question involves multiple technical factors, including the physical properties of wood, the spraying mechanism of the automatic spraying machine, the mixing principle between primer and topcoat, and the desired final surface quality.

This article will provide an in-depth analysis and systematic explanation of the question of whether primer is necessary before painting wood using an automatic spraying machine, from a professional perspective. This will help readers understand the importance of primer and its crucial role in an automated spraying system.

Automatic Spraying Machine: Overview and Features

1. What is an automatic spraying machine?

An automatic spraying machine is a program-controlled device that automatically moves a spray gun in space, enabling continuous, uniform, and batch spraying of target workpieces. Compared to traditional manual spray painting, it offers the following advantages:

• Precise control of the spray path, spray width, and thickness;

• Improved paint consistency and reduced human error;

• Conservation of paint and reduced waste;

• Suitable for standardized and large-scale production.

In the wood products industry, automatic spraying machines are widely used for:

• Painting wooden doors, cabinets, and wardrobes;

• Spraying wood floors and skirting boards;

• Surface treatment of wooden decorative panels, carvings, and frames.

2. Basic Process of Automatic Spraying Machines

A complete automatic painting process generally includes the following steps:

• Sanding → 2. Dust Removal → 3. Primer Application → 4. Drying → 5. Re-sanding → 6. Topcoat Application → 7. Re-drying → 8. Inspection and Packaging

Primer application is an essential step. It not only plays a crucial role in the painting process but is also highly relevant to the characteristics of the automatic spraying machine.

Primer: Definition and Function

1. What is Primer?

Primer is a layer of paint applied to the surface of a workpiece before topcoat application. Its primary function is to provide a good adhesion base for the subsequent topcoat, seal the substrate pores, and improve the overall performance of the coating. Primers and topcoats are typically used in conjunction with each other, and their compositions differ slightly.

2. The main functions of primer include:

• Sealing: Seals the pores and grain of the wood surface, preventing uneven paint penetration;

• Adhesion Enhancement: Improves the adhesion of the topcoat to the wood;

• Penetration Prevention: Prevents discoloration and blistering of the topcoat due to the leakage of wood oils and moisture;

• Sandability: Allows for easy sanding after drying, creating a smooth base surface;

• Cost Saving: Primer costs are generally lower than topcoat, preventing overuse of topcoat.

Therefore, when using an automatic spraying machine to paint wood surfaces, the use of primer directly affects the quality of the coating.

Wood Characteristics and the Necessity of Primer

1. Wood is a Highly Absorbent and Porous Material

Natural wood is inherently highly absorbent and porous. Applying a topcoat directly without a primer can cause the following problems:

• Topcoat penetrating the wood's pores, resulting in a "blurry" or uneven color absorption;

• Surface roughness and uneven coating;

• Defects such as show-through, spots, and cracking;

• Increased topcoat usage, increasing painting costs.

2. Different wood types require different primers

• Softwoods like pine and fir: They are highly absorbent, so primer is essential.

• Hardwoods like oak and beech: They are dense, but still require primer to prevent discoloration.

• Man-made boards like MDF and plywood: The surface fibers are prone to fuzzing, so primer seals and strengthens them.

Regardless of the wood type, to achieve a high-quality topcoat, primer must be applied before spraying with an automatic spraying machine.

Automatic Spraying Machine: Professional Requirements for Primer Spraying

When using an automatic spraying machine for primer spraying, the equipment and process parameters must be properly coordinated. The following aspects are particularly critical:

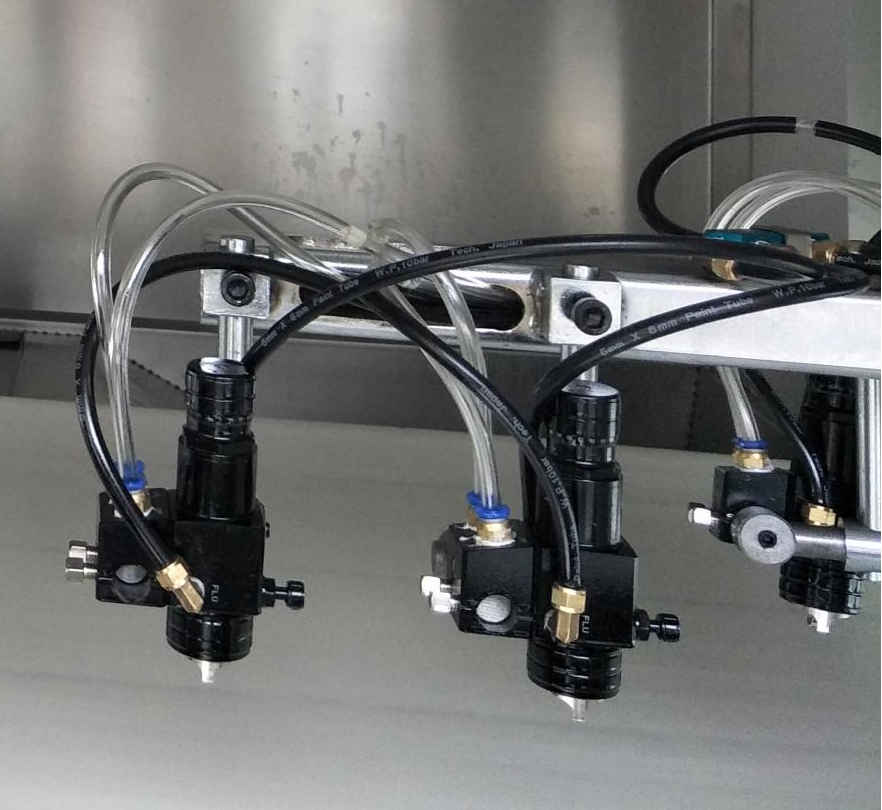

1. Spray Gun Configuration

• Choose an HVLP (High Pressure Low Flow) or LVLP spray gun to achieve fine atomization.

• The nozzle diameter is generally between 1.3mm and 1.8mm.

• Automatically adjust the spray width and paint output to ensure uniform coating.

2. Spray Pressure Setting

• Maintain atomizing air pressure between 1.5 and 2.5 bar.

• Control fluid pressure between 0.8 and 1.2 bar to ensure primer flow and penetration.

• Adjust appropriately based on primer viscosity and ambient temperature and humidity.

3. Spray Path Planning

• Use a PLC or CNC system to set a standardized spray path.

• Maintain a distance of 20–30cm between the nozzle and the workpiece.

• Maintain a stable spray angle and travel speed.

4. Drying and Sanding

After spraying, the primer needs to be placed in a drying tunnel (or infrared curing oven) and allowed to dry completely before a moderate sanding to achieve a smooth surface, providing an ideal adhesion base for the topcoat.

Possible Defects in Painting Without Primer

Omitting the priming step when using an automatic spraying machine can lead to the following negative consequences:

Defect Types | Causes | Consequences |

| Uneven color bleeding | Topcoat penetrates directly into the wood's pores | Varied surface color depths |

| Blistering | Unable to block moisture release from the wood | Blisters in the paint, affecting appearance |

Poor adhesion | The wood surface is too smooth | Easily peeling or flaking the paint |

| Cracking and peeling | Uneven coating thickness | Increased maintenance costs |

| Rough surface | No sanding | Poor quality, lowering product quality |

In summary, not using a primer can seriously affect the quality of the painting. Even an excellent automatic spraying machine cannot compensate for the omission of a process step.

Primer and Automatic Spraying Machine: Coordination Recommendations

To achieve more efficient and high-quality spraying operations, a good system coordination between the primer and the automatic spraying machine is essential. The following recommendations are made:

1. Select a Primer Suitable for Automatic Spraying

• Primers specifically designed for spraying, such as acrylic primers, PU primers, and water-based sealer primers, are recommended.

• Primers with moderate viscosity, good flow, and strong atomization properties should be used.

• Drying times that are compatible with the production line cycle to avoid bottlenecks.

2. Match a dedicated spray path program

• The primer spray path should be different from the topcoat, especially for enhanced coverage around corners and gaps.

• A dual primer program can be set: one spray and one filler to increase fill thickness.

3. Accurately set spray gun parameters

• It is recommended to use a spray gun head specifically designed for primer to avoid frequent nozzle changes.

• For highly viscous primers, increase the fluid pressure appropriately.

Automatic spraying machine: Is primer necessary before painting wood?

The above analysis clearly demonstrates the following:

—Priming is an absolutely necessary process step before painting wood with an automatic spray machine.

Primer plays an irreplaceable role from the perspectives of coating physical structure, wood absorption characteristics, spray quality control, and equipment efficiency. Omitting primer not only fails to save costs, but can also lead to serious consequences such as rework, paint film failure, and customer complaints.

1. If your company is unfamiliar with the primer process, you can first verify the primer formula and spray parameters through manual sample testing.

2. When using water-based primers, pay special attention to drying, ventilation, and humidity control.

3. It is recommended to establish a separate primer spraying line or primer process to improve the efficiency and controllability of the overall automated spraying process.

What types of coatings can XMF machinery equipment handle?

Our machinery supports various coating applications, including roller coating, spray coating, mud coating, and embossing for substrates such as wood, metal, glass, plastic, and ceramic. We supply versatile equipment compatible with different coatings like paints, varnishes, and UV-curable materials, providing clients with flexible, high-quality solutions at affordable prices.