In the furniture manufacturing industry, the surface coating process is a key step in determining product quality, aesthetics, and market competitiveness. To improve coating quality, save paint, and shorten delivery cycles, furniture manufacturers are increasingly shifting from traditional manual operations to automated equipment. The two most representative types of equipment are roller coating machines and automatic spraying machines.

So, in actual furniture production, which is better, a roller coating machine or an automatic spraying machine? This question requires in-depth discussion based on multiple factors, including specific process conditions, product characteristics, and production scale.

This article will provide a systematic and logical comparative analysis of these two types of equipment to help furniture manufacturers clarify their selection and optimize their investment decisions.

What is a roller coating machine?

A roller coating machine uses rotating rollers to continuously and evenly apply paint to the surface of panels or other flat furniture materials. Its primary operating principle is to achieve efficient and consistent surface coating through the relative rotation of a set of rollers, pressure regulation, and a paint supply system.

Core Structure of a Roller Coating Machine:

· Conveyor Platform: Transports the substrate;

· Metering Roller: Controls coating thickness;

· Coating Roller: Transfers the coating to the substrate;

· Scraper System: Removes excess coating;

· Temperature Control System: Maintains coating stability;

· Automatic Cleaning Device (available on some models);

Applications of a Roller Coating Machine:

Roller coating machines are primarily used for substrates with high surface flatness, such as medium-density fiberboard (MDF), plywood, and wood veneer. They are suitable for applying primers, sealers, and functional coatings (such as moisture-proof and mildew-proof coatings).

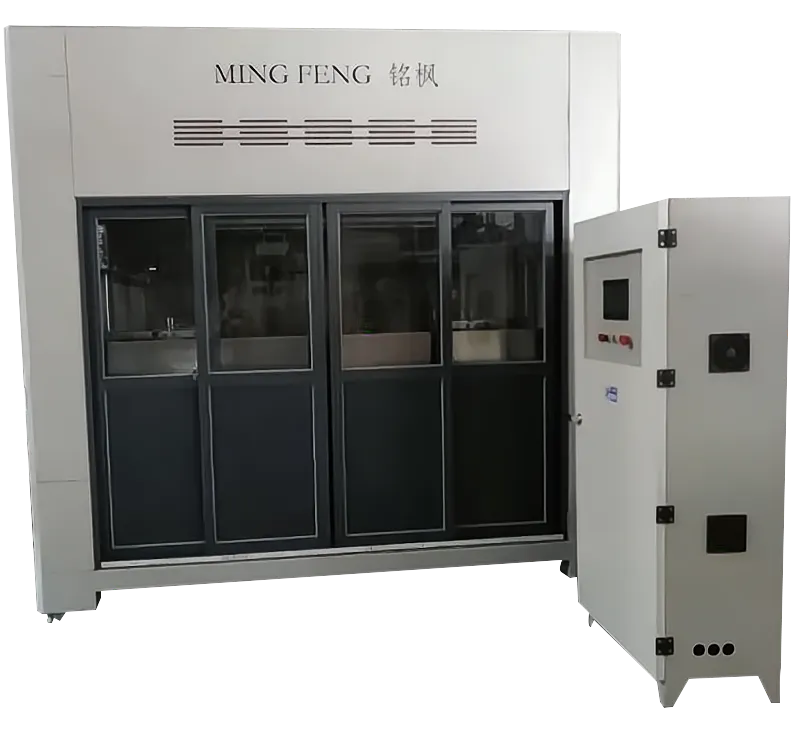

What is an automatic spraying machine?

An automatic spraying machine is an automated device that uses programmable control technology to control the spray gun to spray paint along a set trajectory, achieving uniform coating of large surfaces or complex-shaped furniture parts. It typically utilizes a CNC (Computer Numerical Control) system with three or multiple axes for control, meeting the painting needs of various geometric structures, including flat surfaces, curved surfaces, and corners.

Core Structure of an Automatic Spraying Machine:

· Multi-axis Motion Platform (X/Y/Z/R): Controls the Spray Gun's Movement Path;

· Automatic Spray Gun System: Supports Switching Between Single and Multiple Spray Heads;

· PLC/Touchscreen Control System: Sets Spray Speed, Angle, Thickness, and More;

· Workpiece Conveyor System: Chain, Roller, Rotary, and Other Types;

· Filtering, Dust Removal, and Recovery System: Maintains a Clean Environment;

Applications of Automatic Spraying Machines:

Automatic spraying machines are suitable for coating complex, irregularly shaped furniture components, such as chairs, cabinet doors, table legs, and armrests. They offer significant advantages in coating solid wood furniture, multi-layer structures, and three-dimensional workpieces.

Roller Coating Machine vs. Automatic Spraying Machine: Core Comparison

To facilitate a more intuitive understanding, we systematically compare roller coating machines and automatic spraying machines across several key dimensions:

1. Applicable Materials and Surface Structures

Comparison Dimensions | Roller coating machine | Automatic spraying machine |

| 1. Material Type | MDF, particleboard, plywood, veneer | Solid wood, metal, plastic, board, and special-shaped components |

| 2. Surface Structure | Requires flatness, no bumps or indentations | Can handle complex geometries, curves, and corners |

| 3. Processing Flexibility | Low (standard size required) | High (programmable multi-axis control) |

🔎 Conclusion: Roller coating machines are superior for processing large quantities of standard, flat panels; automatic spraying machines are more adaptable for complex furniture components.

2. Paint Utilization and Coating Uniformity

Comparison Dimensions | Roller coating machine | Automatic spraying machine |

| 1. Paint Utilization | High (over 90%) | Medium (60%-80%, with some spray loss) |

| 2. Coating Uniformity | Extremely high, precise surface thickness control | Good, requires multiple program adjustments and optimizations |

| 3. Edge Control | Poor, weak edge and corner processing | Strong, spray gun can be moved flexibly |

🔎 Conclusion: Roller coating machines offer more stable coating thickness control and paint utilization, making them particularly suitable for primers and large-scale batch processes; automatic spraying machines are superior for detailed coverage.

3. Coating Efficiency and Unit Productivity

Comparison Dimensions | Roller coating machine | Automatic spraying machine |

| 1. Hourly Production | High (suitable for continuous coating) | Medium (depending on program path and part complexity) |

| 2. Stability | Extremely high | Highly program-dependent |

| 3. Changeover Time | Short | Relatively long, requiring adjustments to the spray gun path program |

🔎 Conclusion: Roller coating machines offer greater efficiency advantages for repetitive, standardized batch production; automatic spraying machines are suitable for multi-batch, small-order, and multi-category customization.

4. Operation, Maintenance, and Technical Requirements

Comparison Dimensions | Roller coating machine | Automatic spraying machine |

| 1. Operational Complexity | Medium-low | Medium to high (requires operator programming skills) |

| 2. Maintenance Frequency | Low profile, stable structure | High, spray gun easily clogs, guide rails require cleaning |

| 3. Consumable Parts | Roller, scraper | Spray gun, servo motor, sensor |

🔎 Conclusion: Roller coating machines offer lower maintenance costs due to their simple structure; automatic spraying machines require more specialized technicians for regular inspection and commissioning.

5. Investment Cost and Operating Expenses

Comparison Dimensions | Roller coating machine | Automatic spraying machine |

| 1. Initial Purchase Cost | Relatively low ($10,000-$20,000) | Higher ($25,000 - $60,000) |

| 2. Paint Cost | Low cost, minimal wastage | High, atomization loss is inevitable |

| 3. Energy Consumption | Low | Medium to high, depending on the spray system |

| 4. Operating Labor | Small | Lower, even more economical with automatic loading and unloading |

🔎 Conclusion: Roller coating machines are suitable for businesses with limited budgets and clear production capacity targets; although automatic spraying machines require a higher investment, they offer greater flexibility in product diversity.

Application Scenarios: Roller Coating Machine vs. Automatic Spraying Machine

Applications | Recommended Equipment Types | Description |

| 1. Cabinet doors, bed slats, and flat veneer panels | Roller Coating Machine | High coating consistency for standard flat surfaces |

| 2. Solid wood chairs, table legs, and custom-shaped armrests | Automatic Spraying Machine | Multi-axis control for special-shaped surfaces |

| 3. Small-batch custom furniture | Automatic Spraying Machine | Flexible programming to accommodate product diversity |

| 4. Batch priming and sealing processes | Roller Coating Machine | Low cost and high efficiency |

How should furniture companies choose?

Choosing between a roller coating machine and an automatic spraying machine shouldn't be based solely on the merits of the equipment itself. Instead, a comprehensive assessment should be made based on your company's specific conditions, product process characteristics, and investment capabilities.

Evaluation Dimensions | Roller coating machines are more suitable for businesses that | Businesses better suited for automatic spraying machines |

| 1. Product Structure | Mainly produce flat panels | Large numbers of custom-made or solid wood parts |

| 2. Production Requirement | Batch standardized production | Diverse, small-batch customization |

| 3. Investment Budget | Budget-limited, low-cost operations | Adequate budget, seeking flexibility and precision |

| 4. Technical Capabilities | Experienced operators | CNC/PLC programmers available |

| 5. Coating Requirements | High thickness consistency requirements | High requirements for corner coverage and detailed textures |

Is XMF Machinery suitable for both small and large-scale production?

Yes, our product range caters to both small workshops and large manufacturing plants. Whether you need a single machine or a fully automated coating production line, XMF Machinery can provide reliable, low-cost solutions customized to your production scale. Our factory emphasizes quality and competitive pricing to support customers with varied purchasing budgets.