Painting (also known as surface coating) is a crucial process step in furniture manufacturing. High-quality painting not only determines the aesthetic appearance of furniture but also directly impacts its durability, corrosion resistance, and market value. Therefore, the core equipment that the painting process relies on—the paint sprayer—is an indispensable link in the entire painting production line.

So, what exactly is furniture painting equipment called?

The professional answer is: This type of equipment is generally referred to as an automatic spraying machine or automatic painting machine. Depending on the furniture material and product characteristics, it is often specifically referred to as an automatic wood painting machine.

This article will systematically address this question, focusing on:

1. The names and classifications of various types of furniture painting equipment;

2. The differences and connections between automatic spraying machines, automatic painting machines, and automatic wood painting machines;

3. The structure, functional modules, and application scope of each type of equipment;

4. The specific roles these devices play in the furniture painting process.

What is furniture painting technology?

Furniture painting generally refers to the process of evenly spraying liquid paint in the form of fine particles onto the surface of furniture, creating a continuous, smooth coating.

Main functions include:

· Enhance surface gloss;

· Improve wear, stain, and moisture resistance;

· Improve color and texture;

· Provide an additional layer of protection.

Furniture painting is primarily performed on wood, but can also include medium-density fiberboard (MDF), particleboard, bamboo, plywood, and other materials. Therefore, in actual production, different types of painting equipment are selected based on the material and structure.

Furniture painting equipment: collectively referred to as "spraying equipment"

From an equipment nomenclature perspective, furniture painting equipment can be collectively referred to as spraying equipment. The following technical terms are also commonly used in automated systems:

1. Automatic Spraying Machine

2. Automatic Painting Machine

3. Wood Automatic Spraying Machine

These three types share similarities and differences. The following explains each of these.

What is an automatic spraying machine?

1. Definition

An automatic spraying machine is a coating device that uses a control system (such as a PLC or CNC) to automatically move the spray gun, control atomization, and set the spray trajectory. It is primarily used to mechanize and replace furniture surface painting operations.

2. Structure

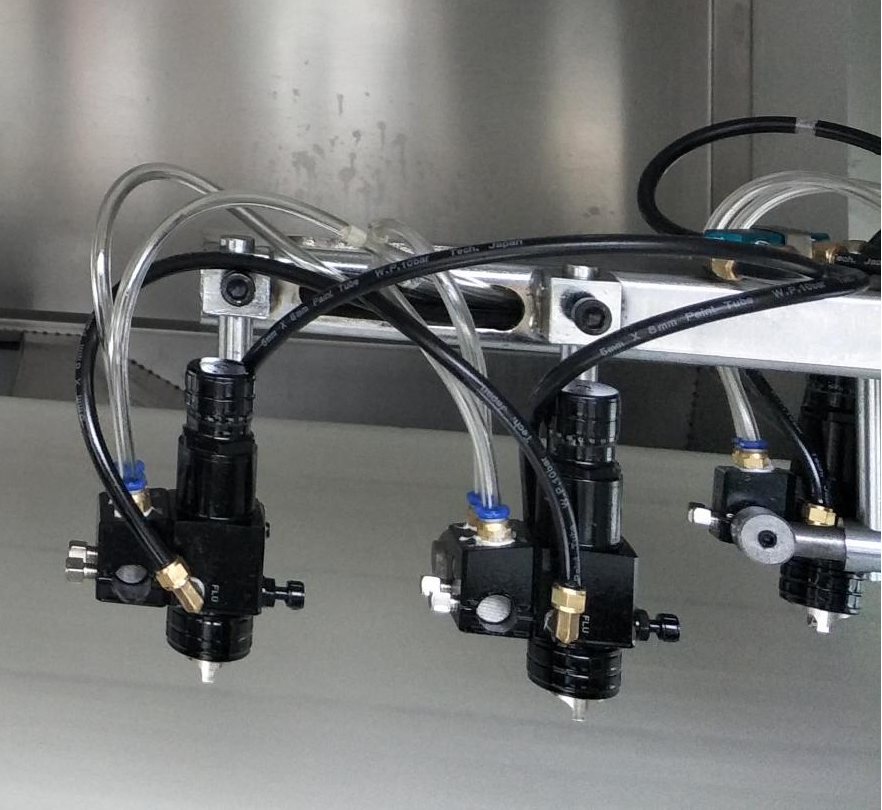

· Spray gun system: Can be configured with 1 to 6 automatic spray guns;

· Conveyor system: Available in chain conveyors, belt conveyors, roller conveyors, etc.;

· Motion control system: X/Y/Z three-axis linkage to execute the spray path;

· Intelligent program system: Supports product contour recognition, trajectory recording, and storage;

· Ventilation and dust removal system: Ensures clean air in the spray chamber and recovers paint mist;

· Automatic cleaning system: Intermittently cleans the spray gun to prevent clogging.

3. Features

· Fully automatic operation, virtually no manual labor required;

· High repeatability and stable quality;

· High spray accuracy, with a control error of less than ±0.5mm;

· 24-hour operation, suitable for large-scale production.

4. Applications

Automatic spraying machines are widely used for painting flat panels, such as:

· Furniture door panels and drawer fronts;

· Decorative panels and speaker panels;

· Home wall panels and cabinet fronts.

What is an automatic painting machine ?

1. Definition and Differences with Automatic Spraying Machines

In a broad sense, an automatic painting machine is equivalent to an automatic spraying machine. For example, in communication between users and suppliers, these two terms refer to the same machine, and this is acceptable. However, in a narrower industrial sense, "spraying" refers more to the process of depositing a pigment layer, while "spraying" may also include more complex processes such as primer, midcoat, topcoat, clearcoat, and UV coating.

Thus, an automatic painting machine focuses more on applying a topcoat (color paint) or decorative paint layer, while a spraying machine is a more general term for surface coating machines.

2. Type Classification

Automatic painting machines can be categorized based on the spraying method:

· Reciprocating automatic painting machines: Spraying is achieved by reciprocating the spray gun;

· Robotic automatic painting machines: A multi-axis robotic arm drives the spray gun in a rotating motion;

· Gantry-type bridge sprayers: Suitable for standard-width panels, with multiple spray guns working in concert;

· Electrostatic sprayers: Apply an electrostatic field between the spray gun and the object to improve adhesion.

3. Performance Characteristics

· Excellent coating uniformity, with little sag or flare;

· Suitable for colored paints, varnishes, metallic paints, etc.;

· Fast color switching, with independent spray gun control;

· The programming system supports custom recipes and parameter storage.

What is a wood automatic painting machine?

1. Equipment specifically designed for wood spraying

A wood automatic painting machine is a spraying machine specifically developed for wood substrates such as solid wood and artificial boards. Compared to general-purpose sprayers, it places greater emphasis on controlling coating penetration, matching paint flow, and preserving wood grain.

2. Features that distinguish them from metal/plastic paint sprayers

· Finely adjust spray speed and paint thickness;

· Supports various types of paint, including water-based, UV, and oil-based paints;

· Often operates in conjunction with a sander and dryer;

· More targeted treatment of details such as knots, edge burrs, and grain clarity.

3. Wood-Compatible Design

· Spray gun angle adjustment of ±45° accommodates grooves and curved surfaces;

· Gentle pressure adjustment prevents paint from eroding the wood grain;

· A multi-stage filter system prevents paint residue contamination;

· Can be combined with sanding, coating, and drying to form a fully automated wood spraying line.

Why choose an automatic spraying machine over manual painting?

While traditional manual painting offers greater flexibility, the advantages of automatic spraying machines are becoming increasingly apparent, primarily in the following areas:

1. Better cost control

· Paint utilization increases to over 85%;

· Reduced labor costs;

· Reduced rework and repair rates

2. High Quality Consistency

· Process control ensures consistent spray width and thickness;

· Ensures a stable coating, smooth surface, and is particle-free;

· Capable of handling complex patterns and detailed edges.

3. Environmentally Friendly and Safe

· Enclosed spray booth reduces VOC emissions;

· Self-cleaning spray gun reduces maintenance pollution;

· Eliminates direct worker contact with chemical coatings.

4. High Efficiency, Supporting Large-Scale Production

· 24/7 Operation;

· Single-machine spraying efficiency far exceeds manual operation;

· Automated production lines connect to upstream and downstream equipment.

Common Furniture Painting Equipment Names

For ease of identification and purchasing, the following are some common furniture painting equipment names:

What are furniture painting equipment called?

In summary:

The equipment used for furniture painting is generally referred to as an "automatic spraying machine," "automatic painting machine," or more specifically, a "wood automatic spraying machine."

These machines not only improve the efficiency, quality, and consistency of the painting process, but also help companies control costs and improve environmental performance. They are essential core equipment in modern furniture production lines.

How can I purchase customized coating machines from XMF Machinery?

To buy customized machinery, simply reach out to our sales representatives with your specific requirements, including substrate type, coating material, and production capacity. Our engineering team will work with you to design and manufacture machines tailored to your needs at competitive prices, ensuring your investment yields maximum efficiency and product quality.