In modern manufacturing, surface coating is a crucial element in a product's aesthetics, protective properties, and overall value. Especially in industries like furniture, hardware, plastics, and woodworking, paint consumption is a significant component of production costs. Therefore, many companies facing the transition from manual spraying to automated methods often ask:

"Will using an automatic spraying machine waste more paint?"

From the perspective of practical technical principles and industrial applications, the answer is a clear no: no, on the contrary, it saves!

This article will systematically explain why automatic spraying machines not only avoid increasing paint waste but can significantly reduce paint consumption over the long term, by focusing on their structure, spraying control principles, paint utilization, paint loss comparison, and system optimization methods.

What is an automatic spraying machine?

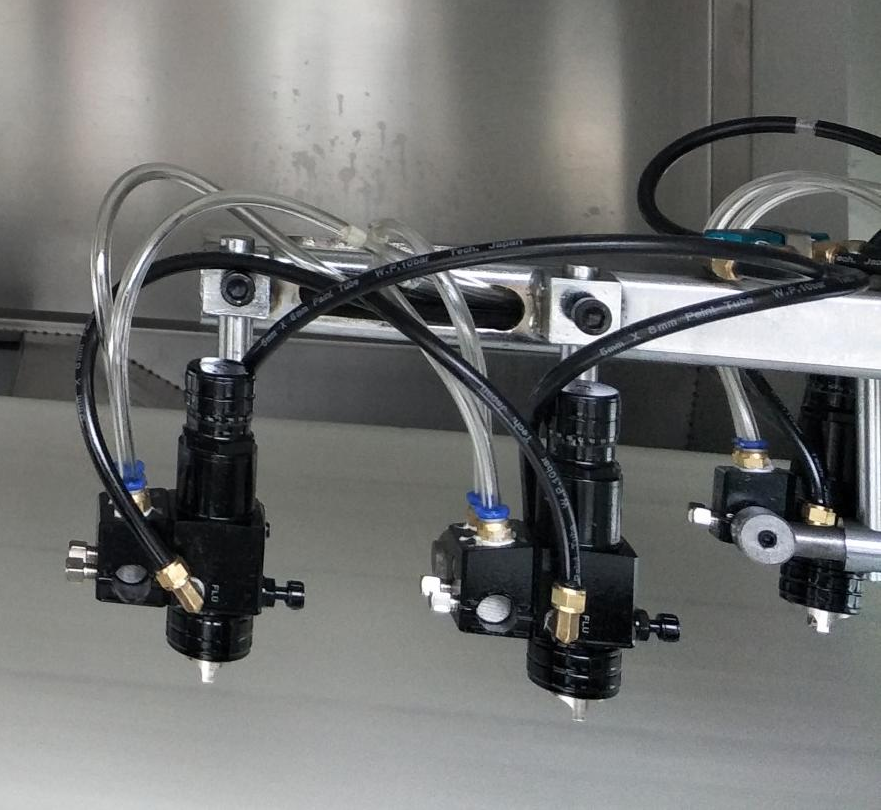

An automatic spraying machine is an intelligent device that uses mechanical control technology (such as PLC and CNC) combined with pneumatic systems, servo motors, intelligent sensors, and programming modules to automatically spray paint, track its trajectory, and control the spraying process. Its goal is to replace traditional manual spraying and achieve a standardized, highly efficient, and low-waste surface coating process.

Main functions of an automatic spraying machine:

· Automatic paint atomization and spraying;

· Automatic multi-axis spray trajectory control;

· Precise control of spray gun opening and closing timing;

· Adjustment of parameters such as paint flow, pressure, and spray width;

· Intelligent matching of atomizing air and air pressure ratio;

· Automatic optimization of the spray path to avoid duplicate spraying;

· Equipped with a paint mist recovery system to reduce paint waste.

Why do automatic spraying machines save paint?

Traditionally, using automatic equipment seems to imply finer paint atomization, potentially resulting in a wider spray spread and resulting in paint waste. However, this view overlooks the precise control technology of automatic spraying systems. In reality, automatic spraying machines achieve significantly higher paint utilization rates than manual spraying.

1. Analysis of Paint Loss in Manual Spraying

The following paint waste phenomena are common in manual spraying:

· Untimely opening and closing the spray gun, resulting in empty sprays;

· Wide variations in spray angle and distance, causing atomized particles to fly;

· Uneven spray width, with thicker and thinner areas, requiring multiple re-sprays;

· Inconsistent coating thickness due to varying operator habits;

· Airless handling, resulting in scattered paint mist and low adhesion;

· High rebound rate, leading to paint loss due to reflection.

In practice, the effective paint utilization rate of manual spraying is approximately 30% to 50%.

2. Advantages of Automatic Spraying Machines in Paint Utilization

Automated spraying machines significantly improve paint utilization through precise calculation and control systems:

Control Mechanism | Waste Reduction Principle |

| 1. Precise spray gun control | The spray gun activates only when contacting the target surface, preventing dry spray |

| 2. Uniform spray speed | Ensures consistent spray width, minimizing overspray and missed applications |

| 3. Automatic workpiece contour recognition | Dynamically adjusts the spray width and spray angle to prevent overspray |

| 4. Coating thickness setting | Controls the film thickness of each spray application to avoid repeated applications |

| 5. Recovery system | Equipped with a paint mist recovery device for reusable paint |

| 6. Optimized air pressure and flow configuration | Reduces atomized particle drift, improving adhesion |

With these control measures, the paint utilization rate of automatic spraying machines can reach 70% to 85%, with some electrostatic sprayers even approaching 90%.

How does the spraying method affect paint utilization efficiency?

Different spraying methods determine the atomized particle size, movement trajectory, and adhesion efficiency of the paint particles. The following compares several common manual and automatic spraying techniques:

1. Air Pressure Spraying

· Manual operation: Unstable distance can easily cause overspray and scattering.

· Automatic control: Stable pressure and distance control, reducing losses by over 20%.

2. HVLP Spraying (High Volume Low Pressure)

· Automatic spraying machines precisely control the air pressure in the spray gun, increasing the adhesion of large particles.

· Avoiding high-speed rebound, allowing paint to adhere more concentratedly to the target surface.

3. Electrostatic Spraying

· In an automatic spraying machine, the electrostatic field causes paint particles to adhere to the charged surface, resulting in virtually no waste.

· High recovery efficiency and reduced air pollution.

4. Automatic Reciprocating Spraying

· Program-controlled spray gun trajectory and speed achieve continuous, uniform spraying across a flat surface, avoiding overlapping layers and missed areas.

Technical Support for Automatic Spraying Machines in Reducing Paint Consumption

1. Intelligent Spray Path Optimization

Automated spraying machines support features such as path simulation, edge recognition, and gap path optimization, effectively avoiding unnecessary re-spraying.

2. Automatic Spray Gun On/Off Control

The spray gun is precisely controlled by program instructions, opening only within the contact area and immediately closing when entering a blank area, preventing "dry spray."

3. Automatic Film Thickness Detection

Some machines are equipped with an online thickness detector, providing real-time feedback on spray results. If the film thickness is too high, the system prompts correction parameters to prevent overspray.

4. Paint Flow Control System

Automated spraying machines are equipped with a flow control valve and pressure sensor to ensure on-demand paint delivery, eliminating excessive flow and waste.

Calculating the paint savings of an automatic spraying machine (theoretical example)

Assuming that manual labor consumes 0.25 kg of paint per square meter of panel, and the optimized automatic spraying machine consumes 0.15 kg of paint:

· Savings of 0.10 kg per day;

· For a daily output of 500 square meters, the daily paint savings are: 500 square meters × 0.10 kg = 50 kg;

· If the unit price of paint is 20 yuan per kilogram, the daily savings are 1,000 yuan;

· With 250 working days per year, the annual savings reach 250,000 yuan.

This does not take into account the reduction in rework, gas consumption, and cleaning costs caused by manual spraying errors.

Common Misconceptions and Clarification

Common Misconceptions | Reality |

| Automatic spraying equipment sprays a wider area and produces a finer spray, which wastes paint | In reality, program control is more precise, resulting in more uniform paint atomization and, in turn, greater savings |

| Automatic spraying requires more cleaning, which also wastes paint | Long cleaning cycles and program control reduce the use of solvents, resulting in lower overall paint consumption |

| Multiple spray guns increase paint output | Multiple spray guns enable collaborative work, eliminating excess paint, and program scheduling prevents duplicate spraying |

Automatic spraying machine not only does not waste paint, but can save

—Combining all the technical analysis and spraying principles explained in this article, we can conclude:

Automated spraying machines do not waste paint. Instead, they effectively improve spraying efficiency and reduce paint loss through precise control, path optimization, system coordination, and paint utilization, making them key equipment for controlling costs and improving yields.

Therefore, when evaluating spraying processes, companies should conduct a systematic assessment based on the actual control system, paint type, and production scale, rather than simply drawing conclusions based on the question of whether automated equipment wastes paint.

Can I get a quote or pricing information for XMF Machinery products?

Absolutely! You can contact our sales department to receive detailed quotes and pricing for our coating and printing machines. We offer transparent pricing with options for bulk orders, customized solutions, and seasonal promotions. Our goal is to provide buyers with affordable, high-quality equipment backed by professional service and support.