12-05/2025

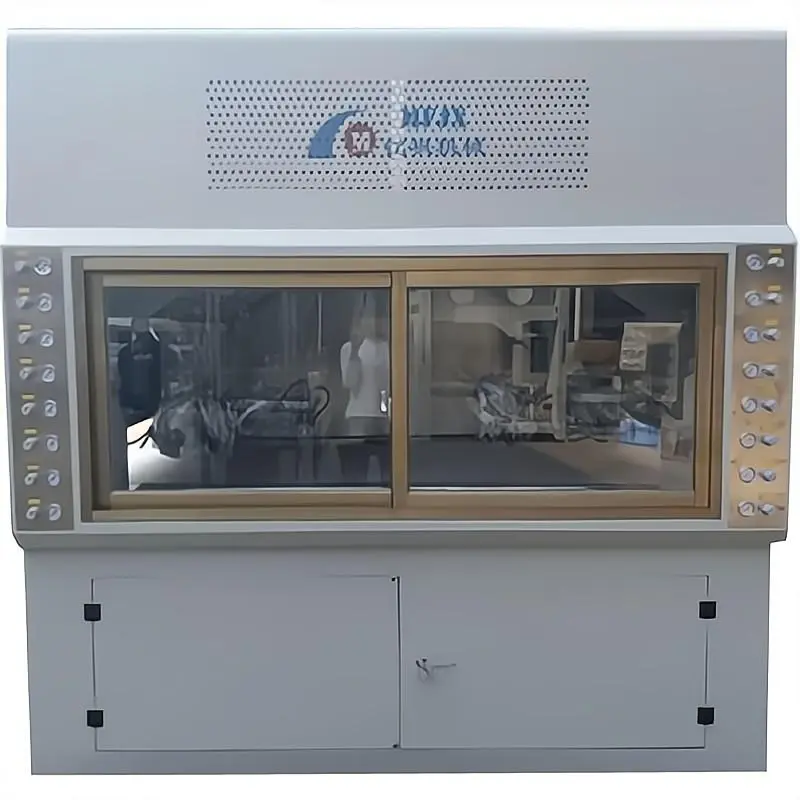

The CNC Automatic Painting Machine supports multi-layer spraying. The CNC system can preset the spraying parameters for each layer, such as spraying angle, spray volume, and spraying time. After the first layer is sprayed, the system automatically waits for the coating to dry or cure and prepares for the next layer.