In modern furniture manufacturing and interior decoration, MDF (Medium Density Fiberboard) is a cost-effective, well-processed man-made board material widely used in cabinets, door panels, wall panels, home decor, and other applications. To enhance the appearance, moisture resistance, wear resistance, and overall quality of MDF, spray painting is an essential and critical process.

For large-scale, standardized MDF production lines, selecting efficient, stable, and precise spray painting equipment is crucial. CNC automatic spraying machines (Computer Numerical Control Automatic Spraying Machines) are widely recognized in the industry as the most suitable type of equipment for MDF painting, due to their intelligent control, high-precision positioning, and multi-station linkage.

This article will focus on the specialized requirements of MDF panel painting and comprehensively analyze the compatibility of different spraying equipment. It will also highlight the structural features, operating principles, technical advantages, and prominent role of CNC automatic spraying machines in MDF painting. This will help readers accurately understand why CNC automatic spraying machines are the optimal solution for MDF panel painting.

What are the technical requirements for MDF panel painting?

Before delving into spray painting equipment, it's important to understand the characteristics and technical challenges of MDF painting:

1. Material Characteristics

• MDF's surface is composed of compressed fibers, which are smooth but porous and easily absorb paint.

• Highly absorbent, requiring a primer to seal pores.

• Uniform structure with no natural wood grain, requiring an even coating to enhance the decorative effect.

2. Painting Objectives

• The spray should be free of streaks, color variations, or buildup.

• The coating must be uniform and fully covered, especially around corners.

• Ensure paint film adhesion, wear resistance, and moisture resistance.

3. Processing Form

• MDF is mostly flat (such as door panels, drawer panels, and partitions), but some may have grooves, patterns, or embossed designs.

• It must be adaptable to batch processing, high repeatability, and complex spray paths.

These requirements make it difficult for conventional manual spray guns, single-axis reciprocating sprayers, or simple rotary nozzle equipment to meet these requirements. Only equipment with high-degree-of-freedom motion control and intelligent recognition capabilities can truly meet the diverse challenges of MDF painting.

Overview and Comparison of Spraying Equipment Types

1. Handheld Spray Gun

• Advantages: Flexible, low investment

• Disadvantages: Uneven coating, low efficiency, reliance on manual experience, and inability to meet stable mass production requirements

• Compatibility: Not suitable for medium- to large-scale MDF production lines

2. Reciprocating Automatic Sprayer

• Advantages: Suitable for standard flat structures, moderate cost

• Disadvantages: Unsuitable for complex edges and three-dimensional structures, fixed path, and weak programming capabilities

• Compatibility: Suitable for painting some standard MDF door panels, but coverage and detail processing are limited

3. Electrostatic Sprayer (primarily for metal/plastic)

• Advantages: High paint utilization

• Disadvantages: Unsuitable for non-conductive materials (such as MDF), posing a safety risk of electrical discharge

• Compatibility: Not suitable for painting MDF panels

4. CNC Automatic Spraying Machine (Recommended)

• Advantages:

Multi-axis intelligent control (usually 3-6 axes) enables complex motion trajectories.

Precise positioning allows for identification of details such as door panel grooves and corners.

Programmed management makes it suitable for mass production and process standardization.

• Disadvantages: Relatively high equipment cost, but high long-term cost-effectiveness

• Compatibility: Highly suitable for MDF board spraying, making it the preferred solution for industrial-grade painting

Core Structure and Operating Principle of a CNC Automatic Spraying Machine

1. Structural Components

• Frame Platform: Stable mechanical support structure with integrated motion mechanisms

• Multi-axis Servo System: Supports three-axis XYZ or six-axis XYZ + UVW motion

• CNC Control System (CNC): Core controller, sets path, speed, and spraying parameters

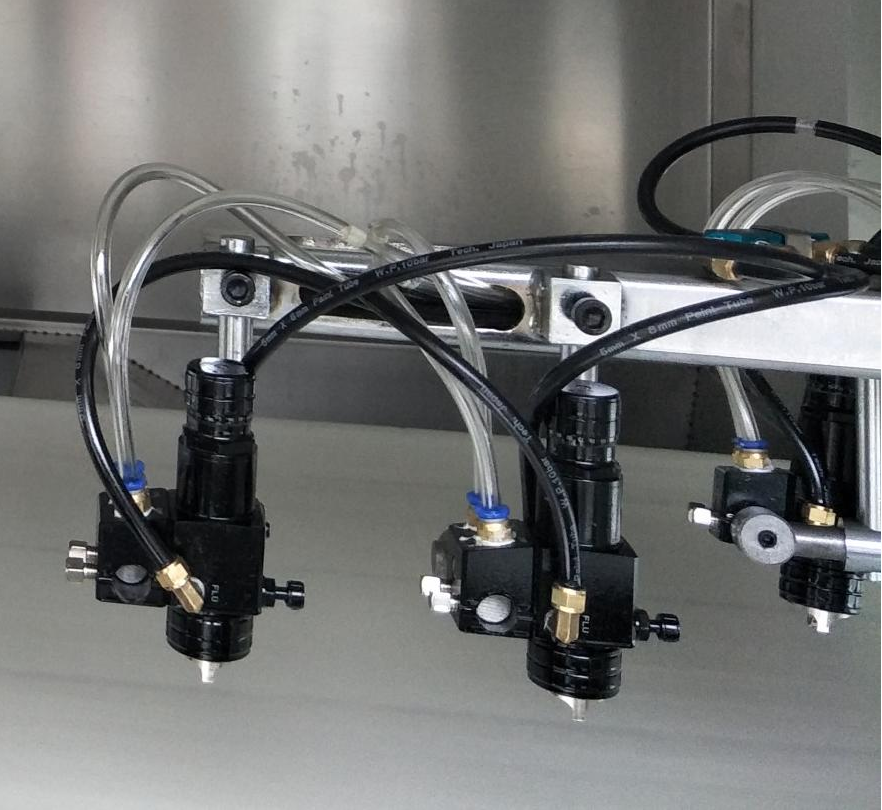

• Automatic Spray Gun Assembly: Opens and closes, adjusts angles, and applies paint according to program control

• Paint Supply System: Equipped with a pressure pump, filter, flow controller, etc.

• Conveyor System: Typically a belt conveyor, operating synchronously with the spraying process

• Spray Booth and Exhaust System: Ensure a clean painting environment and control paint mist dispersion

2. Operating Principle

CNC Automatic Spraying Based on a preset program, the machine identifies the workpiece's trajectory or inputs its coordinates. Using a multi-axis system, the spray gun precisely controls movement in three dimensions, achieving complete coverage of the MDF board's various surfaces, corners, and contoured areas.

The system also automatically controls the spray gun's spray angle, flow rate, and timing, achieving highly consistent industrial painting results.

What are the advantages of a CNC automatic spraying machine for MDF painting?

The five core advantages of a CNC automatic spraying machine for MDF painting are:

1. Precise path control, adapting to complex shapes

MDF door panels and decorative parts often feature irregular designs such as grooves, reliefs, and openings. CNC automatic spraying machines can adapt their path based on CAD drawings, workpiece scans, or trajectory settings, ensuring complete spraying and preventing paint buildup.

2. Uniform and consistent spraying, improving yield rates

The CNC control system enables coordinated control of speed, angle, spray distance, and pressure, ensuring consistent spray thickness and eliminating spray defects such as "blooming," "paint hanging," and "thin spray."

3. Highly automated equipment, leading efficiency

In large-scale MDF board production lines, CNC automatic spraying machines can operate continuously, achieving a fully automated process from loading → positioning → spraying → unloading, significantly improving production efficiency and capacity.

4. Data-driven management facilitates quality traceability

The CNC system supports parameter recording, program storage, and batch management, facilitating future process reproducibility and quality tracking, improving manufacturing management.

5. Compatible with various coating systems

It is suitable for a variety of coating systems, including water-based paint, PU paint, NC paint, and UV paint. Quick switching between spray gun modules allows for integrated multi-process integration.

Configuration recommendations for CNC automatic spraying machines for MDF

When selecting a CNC automatic spraying machine, consider factors such as the size range of the MDF boards, product structure complexity, and production line cycle time. The following are common configuration recommendations:

Configuration Items | Recommended Specifications or Description |

| Number of Axes | At least 3 axes (X, Y, Z), 5/6 axes optional for complex shapes |

| Spray Gun Type | High-atomization, low-pressure spray gun or air-assisted airless spray gun |

| Spray Speed | Adjustable range 1-25 m/min, supports slow edge and corner spraying |

| Programming Method | Point-to-point instruction / Graphics import / Visual recognition automatic modeling |

| Supported Plate Sizes | Maximum support 3000mm x 1300mm (customizable depending on product) |

Coating System | Dual-circuit feed system supports fast primer/topcoat switching |

| Cleaning and Maintenance | Automatic spray gun cleaning, nozzle recovery, and anti-clogging mechanism |

| Environmentally Friendly Emission Treatment | Paint mist filter + exhaust system with reserved VOC control port |

Key Process Control Points for Using a CNC Automatic Spraying Machine

To fully utilize the advantages of a CNC automatic spraying machine for MDF painting, scientific coating process control is also necessary:

1. Board Pretreatment

• Grind the board surface to a smooth surface and remove burrs and loose dust.

• Degrease and dust removal should be performed to ensure adhesion.

2. Spraying Process Parameter Setting

• Primer: Control the thickness to 30-50μm, focusing on sealing pores.

• Topcoat: Control gloss and color uniformity according to decorative requirements.

• Sand and allow the surface to dry thoroughly between coats.

3. Spray Path Planning

• Ensure that corners and recessed areas are fully sprayed.

• Optimize the spray path to avoid duplicate spraying and overspray.

4. Maintenance and Cleaning

• Clean the spray gun and paint supply system promptly after each operation.

• Regularly check axial positioning accuracy to prevent deviation.

Can XMF Machinery provide solutions for different substrates and coating processes?

Definitely. XMF Machinery offers tailored solutions. coating and printing machinery for furniture, flooring, metal, ceramic, plastic and more. As a specialized supplier and manufacturer, we assess substrate characteristics and coating chemistry to provide scientific and rigorous overall coating solutions. Whether you need painting, pattern printing, embossing or drying, we produce customized machines.

You can buy single units or entire lines at competitive prices, with bulk discounts and promotions, ideal for OEM procurement and wholesale sourcing.