In industrial manufacturing and surface treatment technology, surface coating is a crucial process, directly impacting a product's appearance, corrosion resistance, and service life.

With the manufacturing industry's continuous improvement in product quality, production efficiency, and automation, traditional manual spraying is no longer able to meet these high standards. CNC automatic spraying machines have emerged as essential equipment for efficient and high-precision coating operations in many fields.

This article will delve into the definition, core components, operating principles, spraying processes, technical specifications, operating systems, and application advantages of CNC automatic spraying machines, providing readers with a comprehensive, professional, and systematic understanding.

What is a CNC Automatic Spraying Machine?

A CNC automatic spraying machine (Computer Numerical Control Automatic Spraying Machine) is an industrial device that uses computer numerical control technology to precisely control the spray path, spray gun movement, paint spray volume, and motion trajectory, enabling automated spraying operations. Its primary function is to apply uniform, repetitive, and high-quality coatings to various product surfaces according to a pre-programmed process. It is particularly suitable for mass production and high-precision applications.

Compared to traditional spraying equipment, the most significant features of CNC automatic spraying machines are:

· Automatic path control: No manual spray gun operation is required, as the spray trajectory is controlled by a program.

· High repeatability: Consistent spray results are achieved on every product, eliminating human error.

· High precision: Micron-level control is achieved, making it suitable for products with stringent thickness requirements.

· Multi-axis linkage: The machine supports simultaneous movement of the X, Y, Z, or more axes, accommodating spraying of complex, multi-faceted workpieces.

What are the structural components of a CNC automatic spraying machine?

A complete CNC automatic spraying machine typically consists of the following core systems, each of which plays a key role in achieving efficient and precise spraying.

1. CNC control system (CNC controller)

· Function: Controls all spraying paths, trajectory parameters, spray gun opening and closing, and paint flow rate.

· Hardware: Includes a control panel, PLC/motion controller, industrial computer, etc.

· Input methods: Supports CAD path import, manual teach-in, and G-code programming.

2. Motion Execution System (XYZ Multi-Axis Stage)

· Function: Executes programmed spray gun movement.

· Structure: Available in gantry, cantilever, or vertical lift configurations.

· Drive: Servo motor + lead screw/timing belt drive, or linear motor drive.

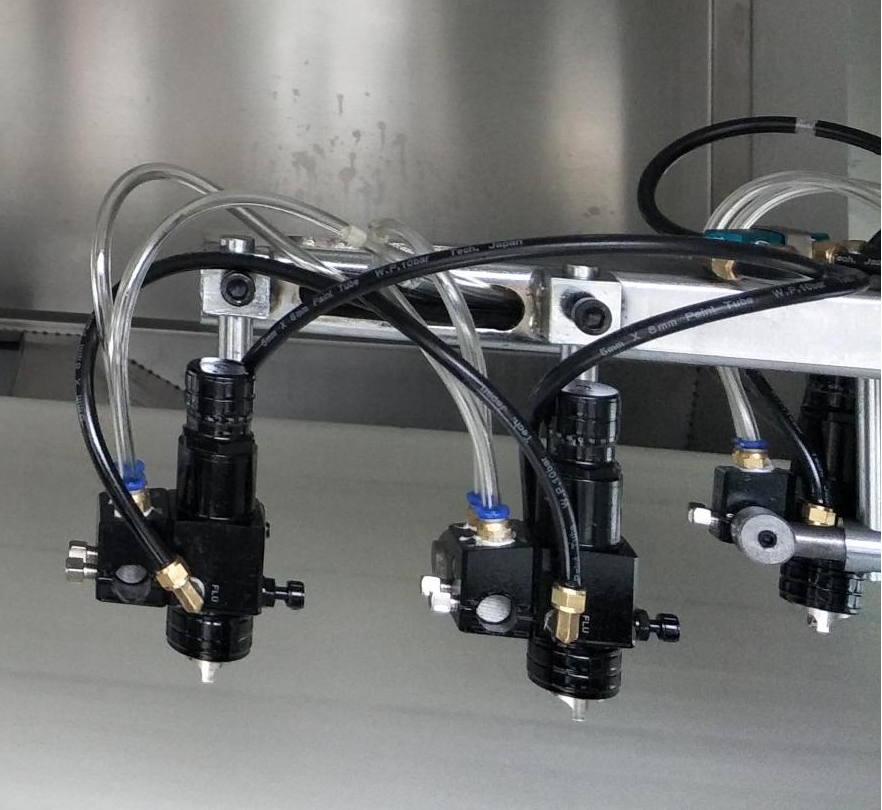

3. Spraying Execution System (Spray Gun Assembly)

· Types: Air spray gun, airless spray gun, electrostatic spray gun, high-pressure spray gun, etc.

· Control: Solenoid valve controls on/off, servo controls spray volume and angle.

· Mounting: Can be fixed to the end of a robotic arm or can independently switch between multiple guns.

4. Paint Supply System

· Components: Paint storage tank, pumping unit, filtration system, pressure and flow control unit.

· Features: Ensures continuous material supply, stable pressure, and controllable viscosity during the spraying process.

5. Base and Worktable System

· Function: Supports the workpiece and provides stable support during the spraying process. Type: Fixed, rotating, lifting, or equipped with a clamp and suction cup.

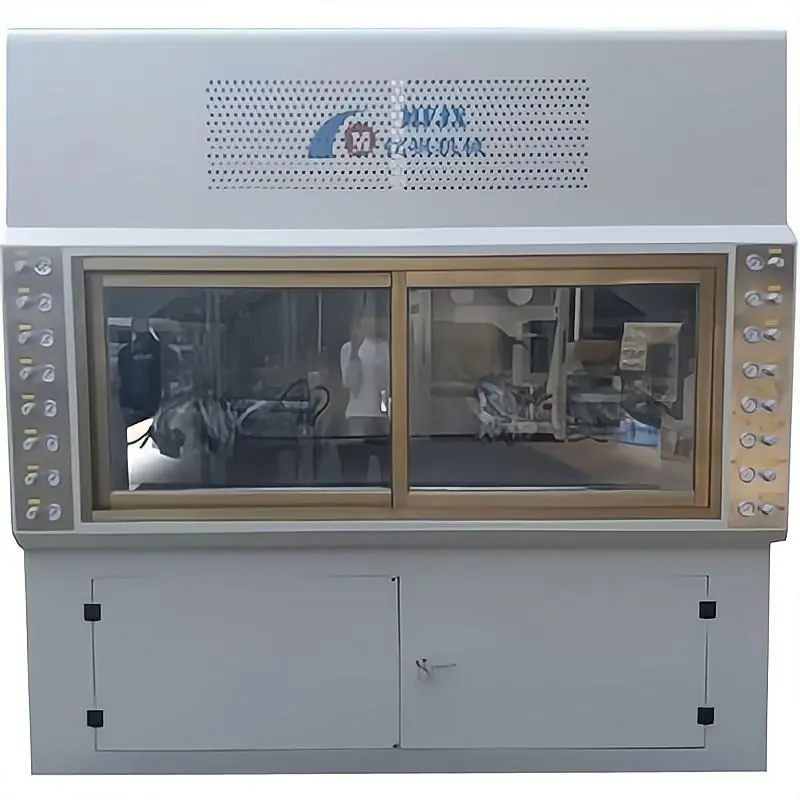

6. Protection and Recovery System

· Includes: Spray booth housing, exhaust system, filter, and paint mist recovery device.

· Purpose: Maintains a clean working environment, improves safety, and recovers sprayed materials.

Key Process Parameters of a CNC Automatic Spraying Machine

To achieve high-quality spraying results, a CNC automatic spraying machine requires precise control of the following core process parameters:

| Process parameters | Description |

Spray gun travel speed | Typically 0.1-1.5 m/s, affecting coating thickness and uniformity |

| Spray gun to workpiece distance | Usually 150-250 mm. A distance too close can lead to paint buildup, while a distance too far can result in insufficient atomization |

| Spray pressure | Paint pump output pressure is typically 0.3-0.6 MPa, depending on paint viscosity and nozzle size |

| Spray gun angle | Direct spray, oblique spray, and rotary spray require adjustment based on workpiece shape |

| Paint flow rate | Adjustable via electronically controlled needle valves and servo valves |

| Path overlap ratio | Overlap between spray patterns is typically 30-50% to ensure uniform coverage |

| Spray gun trigger frequency | Control the spray gun's opening and closing rhythm to achieve special effects such as spot spraying and intermittent spraying |

| Program cycle interval | Control the intervals between multiple spray passes to ensure the coating is dry and layered |

What is the process flow of a CNC automatic spraying machine?

The CNC automatic spraying machine's workflow uses CNC instructions to drive the spray gun for precise spraying. Its core principle is to synchronize the movement of each axis through a preset program, precisely guiding the spray gun along a set path and angle, and applying paint continuously and evenly to the workpiece surface.

The working steps of a CNC automatic spraying machine are as follows:

1. Pretreatment Stage

· Degreasing and dusting the workpiece surface;

· Preheating or surface activation;

· Substrate classification (e.g., wood, metal, plastic) determines whether primer should be applied.

2. Spraying Setup

· Import programs (CAD paths, teach-in trajectories);

· Set spray modes (single-sided, full-cover, corner reinforcement);

· Set spray gun parameters and spray paths.

3. Automatic Spraying

· The CNC control system drives the spray gun in axial motion;

· Spraying is performed continuously, ensuring no missed areas or double buildup;

· Simultaneously monitors various parameters, such as pressure, flow rate, and speed.

4. Curing and Drying (if applicable)

· For thermosetting or UV-curing coatings, a drying oven or UV light box can be used;

· Temperature, humidity, and air velocity control ensure coating performance.

5. Cleaning and Maintenance

· Automatically backflush or clean the spray gun system with solvents after the program is completed;

· Recover residual paint and clean the filter and return line;

· Maintain a clean spray booth and unobstructed exhaust.

What are the advantages of a CNC automatic spraying machine?

The widespread use of CNC automatic spraying machines in various manufacturing scenarios stems from their irreplaceable technological advantages, including:

1. Precise control for improved spray consistency

· Spraying accuracy reaches ±0.05mm;

· Effectively controls coating thickness, eliminating human error;

· Programmed management ensures batch-to-batch consistency.

2. High efficiency, suitable for large-scale production

· Enables 24/7 continuous automated operation;

· Multi-gun linkage and dual-station alternating operation significantly increase production capacity;

· Shortens product spraying cycle time, improving overall production efficiency.

3. Saves paint and reduces waste

· Precisely controls the opening and closing time and spray volume of the spray gun to avoid overspray;

· Precise path control ensures uniform coating and reduces secondary touch-ups;

· Paint recovery system improves utilization.

4. Excellent environmental performance

· Fully enclosed spraying area prevents paint mist from spreading;

· High-efficiency filtration reduces VOC emissions;

· Automatic cleaning reduces manual contact with paint.

5. Adaptable to Complex Workpieces

• Multi-axis linkage and programmable angle control adapt to curved surfaces, grooves, and special-shaped workpieces;

• Integrated vision positioning systems enable automatic identification and spraying of target areas.

Which industries require CNC automatic spraying machines?

CNC automatic spraying machines are widely used in the following industries:

1. Furniture Manufacturing: Wooden doors, cabinets, panels, and other flat and shaped parts;

2. Hardware Products: Surface coating of lamps, locks, bathroom hardware, and handles;

3. Plastic Products: ABS/PVC surfaces for appliance housings, toys, electronic components, etc.;

4. Automotive Parts: Headlights, interior trim, and small sheet metal parts;

5. Electronics Industry: Spraying laptop cases, mobile phone cases, and battery cases;

6. Medical Devices: Surface treatment of housings and metal parts.

Key Points for Operating and Maintaining a CNC Automatic Spraying Machine

1. Operating Precautions:

· Regularly calibrate the coordinate origin and spray gun alignment;

· Use paint that matches the nozzle and pressure parameters;

· Ensure adequate ventilation and a clean environment for the equipment;

· Operators must be trained in CNC and spraying.

2. Maintenance Recommendations:

· Clean the nozzle and feed lines daily;

· Check the lubrication status of the servo motor and guide rails weekly;

· Check the operation of the control system, sensors, cables, and other components monthly;

· Regularly replace filters and lubricants.

What makes XMF Machinery a high-quality and affordable supplier?

Since 2006, XMF Machinery has combined advanced R&D, precision engineering, and strict quality control to deliver high-quality, reliable coating machines. As both a manufacturer and factory-based supplier, we reduce intermediaries and offer low-price, affordable, yet durable equipment.

We tailor solutions to customer needs, ensuring you buy the right machine for your coating process. Along with affordable pricing, we also guarantee excellent service, warranty, and machine lifecycle support.