In the modern furniture manufacturing industry, painting, as a key surface treatment step, directly determines the visual quality, durability, and market competitiveness of furniture products. With the continuous advancement of automation, CNC automatic spraying machines are gradually replacing traditional manual painting methods and becoming the mainstay of furniture painting.

So, what are the specific steps involved in furniture painting using a CNC automatic spraying machine? What are the professional requirements and technical details for each step?

This article will focus on the "CNC automatic spraying machine," providing a systematic, professional, and detailed analysis of the entire furniture painting process, from pre-spraying preparation to the spraying process and post-spraying treatment. This will help companies and practitioners gain a deeper understanding of the application of this technology in furniture painting.

CNC automatic spraying machine: Everything you need to know

Before delving into the process, it's important to first understand the basic definition and core functions of a CNC automatic spraying machine.

1. Definition

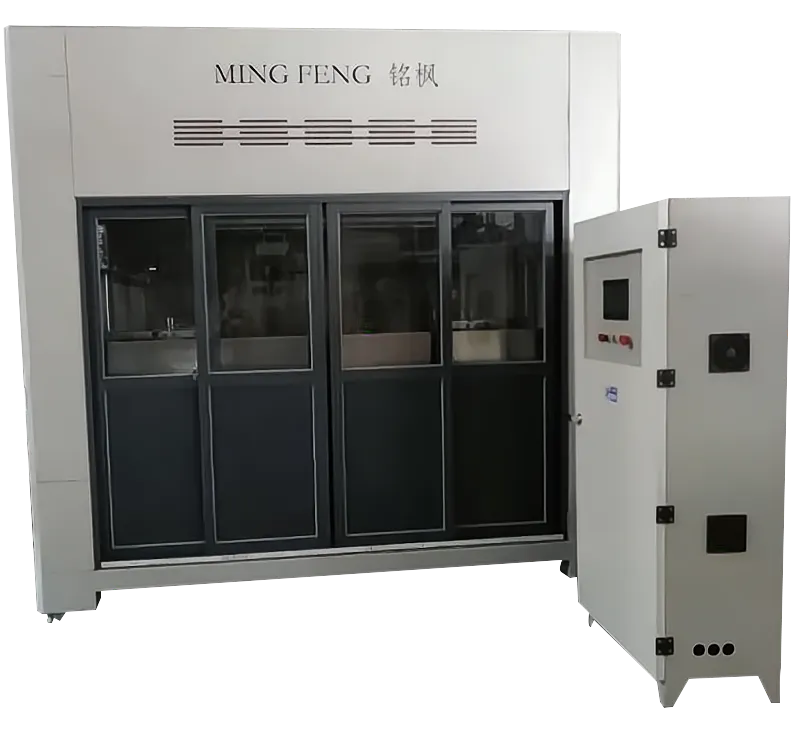

A CNC automatic spraying machine is a device that uses computer numerical control (CNC) technology to perform precise painting operations. It achieves highly consistent, efficient, and high-coverage automated spraying operations through programmable control of the spray gun's position, angle, trajectory, spray speed, and paint volume.

2. Core Components

A standard CNC automatic spraying machine typically includes the following key components:

• CNC system (control system): responsible for setting and executing the spray program;

• Spraying robot arm or spray gun slide mechanism: enabling multi-axis coordinated movement and precise positioning;

• Spray gun and atomization system: atomizing and spraying the paint;

• Feeding and workpiece positioning system: transporting furniture parts to the designated spraying area;

• Paint supply and recovery system: managing paint supply, circulation, and cleaning;

• Ventilation and exhaust system: maintaining a safe and clean working environment.

Automatic Spraying Machine: Overview of the Complete Furniture Painting Process

Furniture painting using a CNC automatic spraying machine generally follows the following complete process:

1. Material Preparation and Surface Pretreatment

2. Painting Area Preparation and Environmental Control

3. CNC Automatic Spraying Parameter Setting and Adjustment

4. Primer Application

5. Primer Drying and Intermediate Sanding

6. Topcoat Application

7. Topcoat Curing (Natural or UV Drying)

8. Inspection and Repair

9. Surface Cleaning and Packaging for Shipment

Each step is explained in detail below.

Automatic Spraying Machine: Detailed Process Flow

1. Material Preparation and Surface Pretreatment

Before painting, the surface of the furniture components must be thoroughly pretreated to ensure a stable paint finish and strong coating adhesion.

a. Substrate Inspection

• Confirm that the material is free of cracks, debonding, and moisture content.

• Ensure that the surface is free of contaminants such as oil and dust.

b. Sanding

• Perform initial sanding on surfaces such as MDF, solid wood, and veneer boards;

• Use sandpaper of varying grits (e.g., P180 → P240) to achieve a smooth finish;

• Thoroughly remove dust with dust removal equipment after sanding.

c. Edge and Corner Finishing

• Perform localized finishing on complex structures or corners;

• Ensure there are no blind spots or missed areas during CNC automated spray painting.

2. Painting Area Preparation and Environmental Control

The spraying environment significantly impacts coating quality. An enclosed, temperature-controlled, and dust-free spraying area must be established:

• Maintain a temperature between 20°C and 30°C and a humidity between 40% and 60%;

• Ensure the floor is anti-static and dust-proof, and the air is filtered;

• Install exhaust ventilation to prevent atomized spray paint from suspending;

• Ensure adequate lighting to facilitate inspection of spray uniformity.

3. CNC Automatic Spraying Parameter Setting and Debugging

This stage is the core of automatic spraying accuracy and primarily involves parameterizing the spraying process through the CNC system:

a. Path Programming

• Set the spray path based on the size and shape of the furniture panel or component;

• Selectable modes include "Reciprocating Path," "Z-Axis Lift Compensation," and "Angle Adjustment Spraying."

b. Spraying Parameter Setting

• Spray gun travel speed (e.g., 300mm/s-1000mm/s);

• Paint flow rate (in ml/min);

• Atomizing and forming air pressures;

• Spray width and overlap ratio;

• Spray height (nozzle-to-workpiece distance) controlled within 200mm.

c. Simulated Spraying Test

• Conduct a spray test on a blank sample;

• Measure coating uniformity, coverage, and any blind spots.

4. Primer Application

Primer is the foundation of the entire spray coating system and is directly related to coating adhesion and the stability of subsequent processes.

a. Primer Selection

• PU primer, water-based primer, UV primer, etc.

• The selection should take into account the material, environmental requirements, and drying method.

b. CNC Automated Spraying Process

• Customize the number of spray coats, generally 1-2 coats.

• Maintain an even spray pattern during spraying to avoid missed coats and buildup.

• Wait 3-5 minutes between each coat before applying the next.

5. Primer Drying and Intermediate Sanding

a. Drying Method

• Natural drying (30 minutes-2 hours) or low-temperature drying.

• UV primer requires a UV curing machine (curing in seconds).

b. Intermediate Sanding

• Sand the primer layer with P320-P400 sandpaper.

• Remove air bubbles and burrs to improve surface smoothness.

• Remove dust with an air gun or vacuum cleaner after sanding.

6. Topcoat Application

Topcoat application is a critical step in determining the appearance and texture of furniture. Automated spray systems require greater precision during this stage.

a. Topcoat Selection

• High-gloss, matte, pearlescent, and open finishes are available.

• Paint viscosity is controlled within the recommended range to ensure uniform atomization.

b. Spraying Process

• The CNC system precisely controls spray gun movement and spray coverage.

• Topcoat is typically applied in two to three coats to ensure color saturation.

• Time intervals should be controlled between coats to prevent cracking caused by wet interlayers.

7. Topcoat Curing

a. Drying Method

• Solvent-based topcoat: Requires drying at room temperature or under heating for at least 24 hours.

• UV-based topcoat: Cures instantly with a UV lamp (in seconds).

• Water-based paint: Requires a combination of air drying and low-temperature drying, with drying time depending on the environment.

8. Inspection and Repair

Each painted furniture component must undergo a quality inspection process to ensure it meets coating standards:

a. Inspection Details

• Coating thickness (typically 40-80μm);

• Surface smoothness and gloss;

• Inspection for bubbles, sags, missed sprays, orange peel, and other defects.

b. Repair Procedures

• Localized coating defects are repaired using a manual spray gun;

• Components with severe defects are re-applied to the coating process.

9. Surface Cleaning and Packaging for Shipment

Furniture components that have been painted and passed inspection undergo final inspection, cleaning, and packaging:

• Wipe surface dust with a dust-free cloth;

• Cover the coating with protective film to prevent handling damage;

• Sorted into storage or loaded onto trucks for shipment.

Automatic Spraying Machine: Technological Advantages in the Painting Process

CNC automatic spraying machines offer the following key advantages throughout the furniture painting process:

Project | CNC automatic spraying machine | Manual spraying |

| Spraying consistency | Extremely high, programmable control | Difficult to achieve perfect consistency |

Production efficiency | Continuous operation, high-speed spraying | Low efficiency, requires intermittent work |

| Paint utilization | Up to 85%-90% efficiency | High loss and waste |

Labor dependency | Low, one person can control multiple machines | Highly dependent on skilled labor |

| Safety and environmental protection | Spray recovery and exhaust system | Large paint mist dispersion |

| Complex workpiece handling | Programmable | Requires manual judgment |

The above system analysis demonstrates that using CNC automatic spraying machines for furniture painting not only significantly improves painting quality and production efficiency, but also standardizes the entire painting process. Its CNC precision, high degree of automation, and excellent consistency make it an indispensable painting tool in modern furniture manufacturing.

The complete furniture painting process includes:

• Material pretreatment;

• Environmental preparation;

• CNC program setting;

• Primer spraying and sanding;

• Topcoat spraying and curing;

• Quality inspection and refinishing;

• Surface cleaning and packaging.

Each stage must be optimized to meet the performance of the CNC automatic spraying machine to ensure optimal painting results. Understanding and mastering these processes is of profound significance for enhancing the competitiveness of furniture manufacturers.

How does your global sales and logistics process work?

XMF Machinery coordinates international sales, logistics and installation from our Foshan base. Once you purchase machinery, we manage packaging, international shipping, customs clearance and destination delivery.

As a direct manufacturer and supplier, we control the full process, providing reliable scheduling, quotes on freight, and options for bulk purchase shipping discounts.