In the wood processing and furniture manufacturing industries, CNC automatic painting machines have gradually become mainstream spraying equipment. Their high efficiency, precision, and automation have significantly improved the surface treatment efficiency and coating quality of wood products.

When companies purchase or use this type of equipment, in addition to considering production capacity and coating results, another important question often arises: Does a CNC automatic spraying machine consume a lot of power?

This article will provide a detailed analysis of the power consumption of CNC automatic painting machines, helping users clearly understand their actual energy consumption levels and providing theoretical support for energy conservation and consumption reduction.

Introduction to CNC Automatic Painting Machines

Before discussing power consumption in depth, it is necessary to first have a comprehensive understanding of the system structure and operating procedures of CNC automatic painting machines.

1. What is a CNC automatic painting machine?

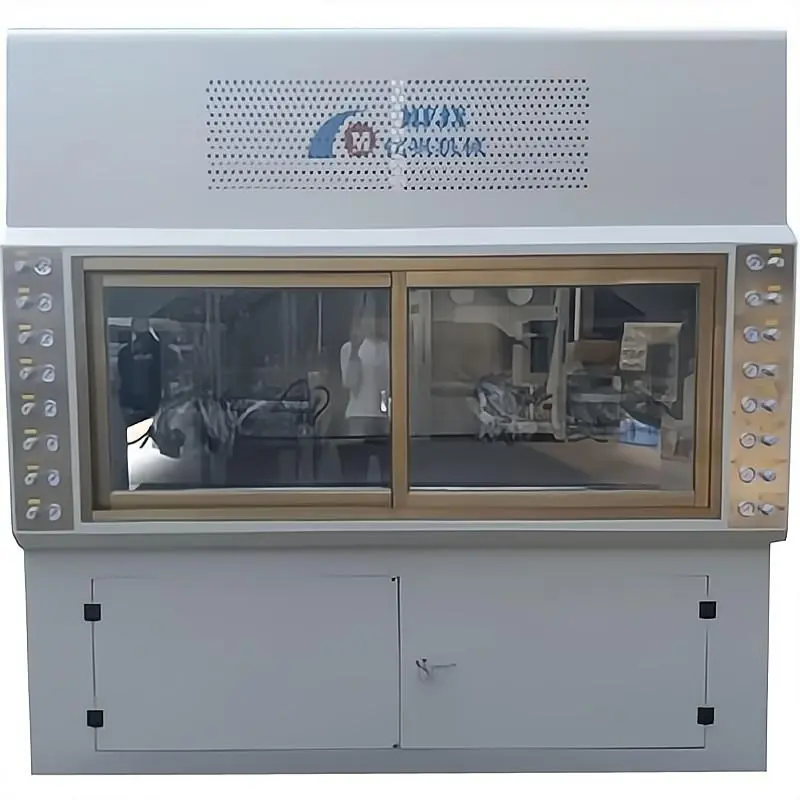

A CNC automatic painting machine is an automatic wood painting machine equipped with a computer numerical control (CNC) system. Its core function is to apply surface coatings to wood workpieces (such as furniture door panels, cabinets, and decorative panels) using a program-controlled multi-axis spray gun.

2. Main Components of the Equipment

The power consumption of a CNC automatic spraying machine is primarily distributed across the following systems:

• CNC system and drive motor system: Controls the machine's multi-axis linkage (usually three or four axes), used for positioning and motion trajectory control, primarily achieved through servo motors, stepper motors, or linear actuators.

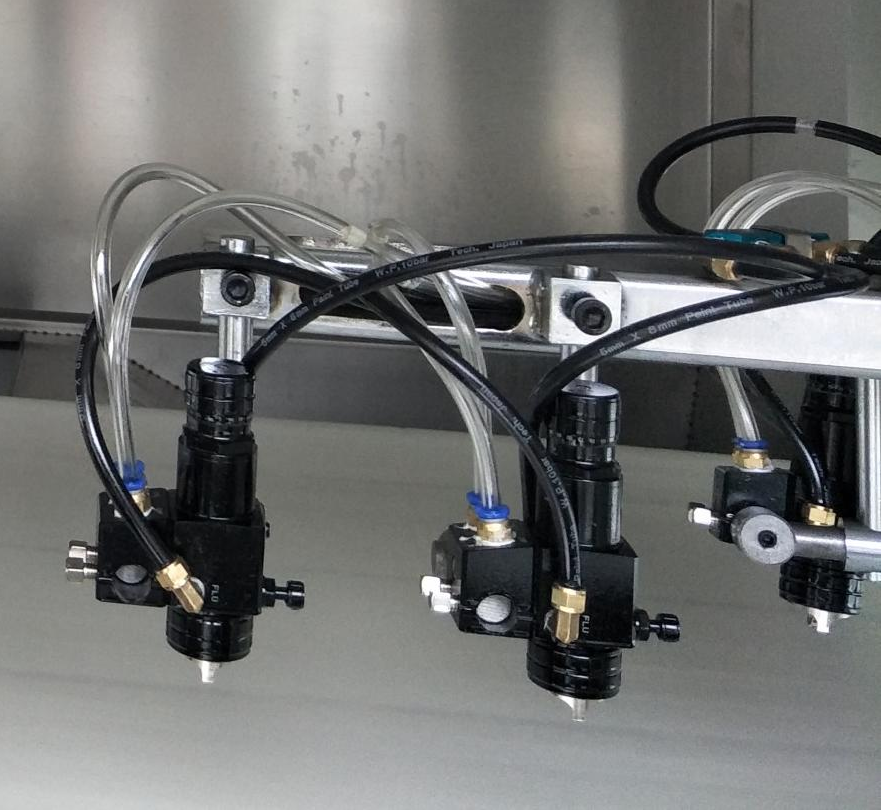

• Spraying execution system: Includes high-pressure or low-pressure spray guns, air pumps, paint pumps, and other components. Some pneumatic devices are controlled by the electronic control system.

• Conveying system: Automatically moves workpieces in and out, typically driven by electric rollers or chain motors.

• Paint mist treatment and exhaust system: Recovers paint mist and purifies exhaust gas, typically powering large centrifugal fans or high-efficiency filtration units.

• Auxiliary systems such as lighting, sensors, and touch interfaces: Although these systems are not high-energy consuming, they also consume power continuously.

This shows that the power consumption of a CNC automatic spraying machine does not come from a single module, but rather the combined power consumption of multiple power-consuming systems operating in parallel.

What are the sources of power consumption in a CNC automatic painting machine?

1. Drive System Power Consumption

CNC automatic painting machines typically use a high-precision servo drive system to control the movement of the spray gun or worktable. Taking a three-axis control system as an example, the rated power of the three servo motors is generally:

• X-axis: 0.75kW

• Y-axis: 1.5kW

• Z-axis: 0.4kW

If operated continuously, the total power consumption is approximately 2.65kW. However, because the motors are not always fully loaded, the actual average power consumption is slightly lower than the theoretical value, approximately 1.8-2.2kW/h.

2. Spray System Power Consumption

• High-pressure air pump (if electric): Power consumption is approximately 1-2kW;

• Paint delivery pump: Power consumption is approximately 0.2-1kW, depending on pressure and volume;

• Spray gun control module (solenoid valve, heater, etc.): Power consumption is relatively low, generally less than 0.5kW;

The total power consumption of the entire system when operating is approximately 1.5-2.5kW/h.

3. Conveyor System Power Consumption

Common roller conveyor lines or chain drive systems have main motor power between 0.75 and 1.5 kW. If the equipment supports multi-station parallel operation, power consumption rises to approximately 2 kW/h.

4. Exhaust and Purification System Power Consumption

This is one of the most energy-intensive components of a CNC automatic spraying machine. Its operating purposes include:

• Extracting paint mist from the spray chamber;

• Maintaining a negative pressure environment;

• Filtering and discharging exhaust gases.

Depending on the air volume design, the main fan power typically ranges from 3 to 7.5 kW. In large spray booths, this power can reach 11 kW or higher.

5. Auxiliary System Power Consumption

This includes lighting, PLC systems, HMI operation screens, sensors, cooling fans, etc. Each of these devices consumes minimal power individually, and their combined power consumption generally does not exceed 0.5 kW/h.

CNC automatic painting machine power evaluation

Based on the above analysis, the total power consumption of a single CNC automatic painting machine at full load is estimated as follows:

System components | Power Range (kW) |

| Control and drive system | 1.8 to 2.2 |

| Spraying execution system | 1.5 to 2.5 |

| Conveying system | 1.0 to 2.0 |

| Exhaust and filtration system | 3.0 to 7.5 |

| Auxiliary equipment system | 0.2 to 0.5 |

| Total | 7.5 to 14.7 |

Therefore, the average operating power of a standard CNC automatic painting machine is between 7 and 15 kW, depending on:

• Equipment model (size, spraying capacity);

• Whether it uses a continuous conveying system;

• The size and power of the fan exhaust system;

• The number and type of spray guns (high-pressure, electrostatic, low-pressure);

• Usage pattern (full-time operation, intermittent operation, etc.).

If calculated as operating 8 hours per day, the daily power consumption of a single machine is approximately 60 to 120 kWh.

Is a "CNC automatic painting machine" considered a "high-energy-consuming device"?

The question of "Does a CNC automatic painting machine consume a lot of power?" cannot be determined without considering the following factors:

1. Compared to manual spraying equipment

Manual spraying equipment primarily consumes power in the air pump and lighting, and while its overall energy consumption is extremely low, its efficiency is also far lower than that of a CNC automatic painting machine. If compared based on unit output—that is, "power consumed per square meter of workpiece sprayed"—CNC automatic painting machines are often more energy efficient than manual spraying. In other words, while their total power consumption is higher, their unit energy consumption is lower.

2. Compared to Other Woodworking Equipment

In the woodworking industry, other high-energy-consuming equipment, such as CNC engraving machines (power 10kW+), UV curing machines (15-30kW), and large sanders (8-12kW), have comparable unit-time power consumption to CNC automatic spraying machines. Therefore, from the perspective of overall industry energy consumption, CNC automatic painting machines fall into the medium-to-high power consumption range.

3. Actual Operating Time Control

CNC automatic spraying machines do not operate continuously 24 hours a day; they are typically operated in shifts based on order volume. Furthermore, some systems (such as exhaust fans and conveyor lines) can be configured with intermittent start-stop modes or variable frequency control, significantly reducing overall power consumption.

How can I reduce the energy consumption of CNC automatic painting machines?

To effectively control the power consumption of CNC automatic spraying machines, companies can use the following strategies:

1. Select variable frequency control equipment

Use variable frequency drive speed control for main power systems such as fans and motors, automatically adjusting power based on load, to avoid waste caused by full-load operation.

2. Set automatic standby mode

When no workpieces are entering the machine, it automatically switches to low-power mode and shuts down high-energy-consuming components (such as the spray gun system and exhaust system), reducing inefficient energy consumption.

3. Rationally schedule production batches

Centralized spraying task scheduling can improve spraying efficiency and reduce energy waste caused by frequent starts and stops.

4. Optimize spray gun atomization efficiency

Selecting a spray gun with high atomization efficiency and a wide spray pattern can help shorten spraying time and indirectly reduce system energy consumption.

5. Regular maintenance and care

Poor equipment lubrication, pipe blockages, and dust accumulation in air ducts can reduce system efficiency and increase energy consumption. Regular maintenance can keep the equipment in optimal operating condition.

CNC automatic painting machine: Energy consumption isn't the issue, efficiency is the standard

In summary, while CNC automatic painting machines do consume more electricity than traditional manual spraying methods, the improvements in energy efficiency, production capacity, and quality far outweigh the resulting increased electricity costs. In a modern furniture manufacturing environment, their energy consumption is within a reasonable range and well within the company's control.

Therefore, the scientific answer to the question, "Do CNC automatic spraying machines consume a lot of electricity?" is:

In terms of theoretical power, CNC automatic spraying machines are medium-to-high power devices. However, judging by unit output and spraying efficiency, they do not waste electricity and instead demonstrate greater energy efficiency and cost-effectiveness.

For companies, rather than focusing excessively on "high power," it's better to evaluate equipment operating efficiency, unit energy consumption, and overall cost to make a more rational and professional equipment selection decision.

Do you offer discounted or promotional pricing for bulk orders?

Yes. As a direct factory and coating equipment supplier, XMF Machinery offers special promotions, discounts, and lower prices for wholesale purchasing or large volume orders. When you buy multiple machines—such as full coating lines or combinations of rollers, sprays, embossers—we can provide bundled quotes with volume discount, favorable shipping terms and after-sales support packages.