12-04/2025

Types of Wood Grain Printing Machines include:

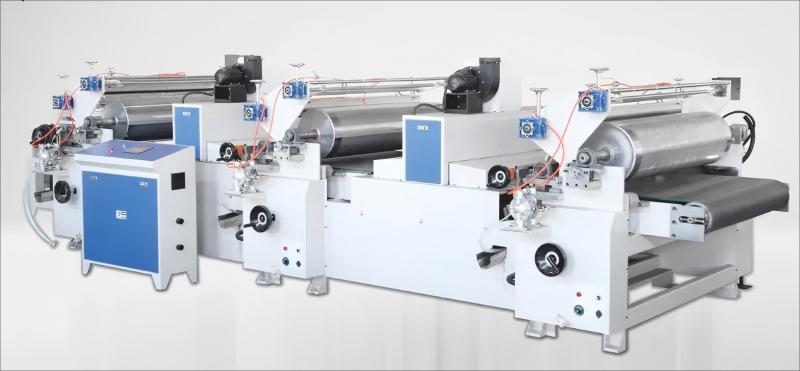

1. Gravure roller Wood Grain Printing Machine

2. Digital UV inkjet Wood Grain Printing Machine

3. Thermal transfer Wood Grain Printing Machine

4. Water transfer wood grain printing system

5. Screen printing for wood grain