(High Precision Single Color Printing Machine For Wood Grain)

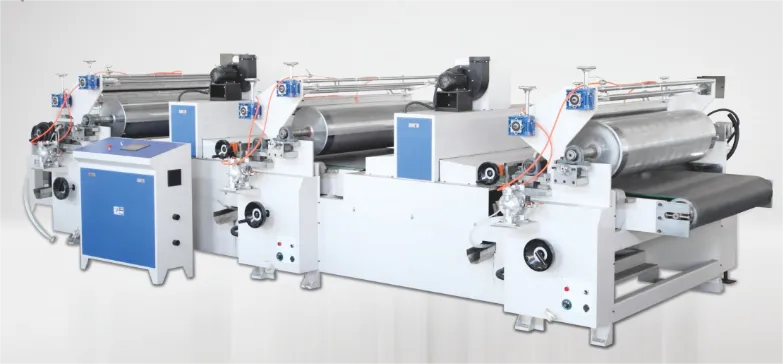

(Two Color Printing Machine For Woodgrain)

To put it simply: Single-color wood grain printing machines are suitable for single-layer effects focused on the "main grain/base grain," offering quick setup, low cost, and easy maintenance.

Two-color wood grain printing machines utilize two sets of printing units for layered overprinting, enabling simultaneous printing of "main grain + shadow/annual ring enhancement" or "base grain + surface grain." They generally outperform single-color printing machines in terms of depth, three-dimensionality, color stability, and yield, making them suitable for higher aesthetic standards and more demanding decorative finishes.

Based on process logic, we'll systematically analyze the differences between the two, including structural design, image performance, production capacity, color control, coordination with the UV curing stage, cost and maintenance requirements, and typical application boundaries, to help you understand and make the right choice.

Single-color vs. Two-color Wood Grain Printing Machines: What Are They?

1. Common Principle (Rotary Transfer Printing)

Whether single-color or two-color, both utilize rotary transfer printing: the wood grain pattern is engraved on a metal gravure cylinder (commonly a copper or steel plate). An inking system fills the grooves with ink, a doctor blade removes any excess ink from the surface, and an embossing roller transfers the ink from the grooves to the board surface under pressure. When connected to a UV wood dryer or hot air/IR section, a continuous production line with simultaneous printing and curing is possible.

2. Structural Differences (One Printing Unit vs. Two Printing Units)

• Single-color wood grain printing machine: Equipped with one printing unit (a set consisting of a gravure cylinder, an inking doctor blade, and an embossing roller), it produces one layer of the pattern in a single pass.

• Two-color wood grain printing machine: Equipped with two printing units arranged in tandem, this machine typically features an intermediate curing or shortwave/UV emergency curing after the first color, before applying the second color. Servo synchronization and color registration control ensure precise overprinting of the two patterns, resulting in more realistic wood grain gradations (e.g., "grain master" + shadow/annual rings) or "ground grain + surface grain").

3. Key Specifications (Based on Industry Standards)

Effective Width, Thickness, and Line Speed: For single-color and two-color models on the same platform, effective widths range from 0–1320 mm, processing thicknesses from 2–80 mm, conveyor speeds from 0–20 m/min, and a minimum processing length of approximately 300 mm. These parameters are listed as standard on many manufacturer websites.

• Equipment Dimensions: Monochrome printers are relatively compact (e.g., approximately 2200 × 2800 × 1700 mm). However, two-color printers, due to their dual units and color register mechanism, are significantly longer (approximately 6000 × 2800 × 1700 mm).

• Movement and Registration: Many two-color printers emphasize full servo drive, automatic balancing/automatic increase/decrease to eliminate color differences, and precise color registration. They also offer performance claims such as "pattern fidelity of 98%+," reflecting their design emphasis on multi-color registration.

Monochrome vs. Two-Color Wood Grain Printing Machines: Which Has Better Graphics?

1. Graphics Logic of Monochrome Wood Grain Printing Machines

Suitable for: Wood grains that can be expressed with a single pattern, such as "straight grain/main annual ring grain" or "basic shading," or when used in conjunction with a base coat to highlight grain direction and line sharpness.

Advantages:

• Excellent edge sharpness: With only one transfer set, the process chain is shortened, avoiding subtle smearing caused by overprinting. • Fast plate changeover: Changing patterns is as simple as changing a single roller, minimizing machine setup time.

• Low cost: Ink consumption and process steps are more economical.

• Limitations: Using a single pattern layer makes it difficult to achieve both texture and shadow, resulting in inherent limitations in terms of "three-dimensionality," "depth," and the progression of knots and growth rings. Using darker colors to enhance contrast can easily compromise transparency and realism.

2. Graphics Logic of Two-Color Wood Grain Printing Machines

Suitable for: Layered overprinting, typically using the following:

• First color: Lays down the main grain or base texture, defining the direction and main lines of the wood grain.

• Second color: Adds shadows, growth rings, knots, and localized depth, achieving spatial depth without creating a heavy, heavy print with a lower ink application.

Advantages:

• Deep layers and high fidelity: The two patterns interact with each other, simulating the light and dark variations and pore details of natural wood grain. • Stable color registration: Dual servo systems, automatic balancing, and color difference compensation minimize color shift and achieve high repeatability.

• Note: Two-color overprinting requires stricter squeegee angle/pressure, plate roller concentricity, rubber roller hardness, and UV dosage distribution. If the second color pattern is fine and the UV dosage is insufficient, "drying on the surface but not on the inside" or poor interlayer adhesion can occur. A combination of intermediate curing/low-energy pre-curing and a top-layer full cure is necessary to lock in edges and interlayer bonding.

Cooperation with the UV Curing Section (Why They Are Often Connected)

Whether single or two-color, if using UV ink or subsequent UV varnish, connecting to a wood UV dryer offers three key reasons:

• Cycle Matching: Set the conveyor speed according to the recommended dosage (J/cm²) on the ink datasheet and the measured irradiance (mW/cm²) on site to achieve sub-second curing and ensure that details are free of smearing after color registration.

• Interlayer Adhesion: A combination of single-color printing + topcoat or two-color printing + topcoat, using an intermediate/final curing strategy, ensures interlayer chemical bonding and surface tension matching.

• Durability and Handfeel: Many panels require a transparent, wear-resistant varnish and UV curing to achieve a harder, scratch-resistant, and easy-to-clean surface.

Single-Color vs. Two-Color Wood Grain Printing Machine: Cost, Changeover, and Maintenance

1. Equipment and Tooling

• Single-Color Wood Grain Printing Machine: Low purchase price and tooling investment. Typically, only one set of pattern rollers is required; changing patterns requires only one roller, resulting in minimal setup time.

• Two-Color Wood Grain Printing Machine: Requires two plate rollers and a complete color position control mechanism, making initial assembly and proofing more complex. However, for long-term orders, the cycle time and yield gains from imaging two layers in a single pass often offset the initial price difference.

2. Consumables and Energy Consumption

• Ink: The total ink load for a two-color press may be slightly higher, but since the "second color" often uses low coverage and low ink volume for shading, it's not necessarily doubled.

• Varnish/Primer: The two are comparable, depending more on the product's positioning.

• Energy Consumption: If a UV stage is included, the key is to match the dosage and line speed. Since two-color presses produce two layers in a single pass, the overall energy consumption per square meter may not be higher than that of a single-color press with two passes.

3. Changeover Efficiency

• Single-color presses: Simply replace the rollers and ink; color positions do not require plate registration, resulting in faster machine setup.

• Two-color presses: Replace both rollers and perform phase/registration correction. If the pattern changes frequently, establish a standardized plate registration process and process charts, using "reference lines/marker points" to expedite correction.

4. Maintenance Key Points

• Scraper System: Angle, pressure, and blade straightness affect inking, plate cleaning, and edge sharpness;

• Rubber Roller: Regularly inspect hardness, surface accuracy, and circular runout to prevent uneven nip;

• Plate Roller Cleaning and Storage: Prevent corrosion and scratches to prevent blockage of fine lines and shallow grains;

• Conveyor and Platform: Maintain a flat surface and cleanliness to reduce the entry of dust and particles into the nip;

• UV Section: Regularly measure irradiance/dose decay curves, and replace lamps or calibrate LED modules as needed.

Single-Color vs. Two-Color Wood Grain Printing Machine: How to Determine Which One You Need?

1. If Your Texture Goal is:

• Requires only a clear main grain, emphasizing a simple "base color + one layer of grain": A single-color wood grain printer is preferred.

• Emphasizes the natural wood's layers, shadows, and knot details, and desires a higher degree of fidelity: A two-color wood grain printer is preferred.

2. If your "Order Structure/Cycle Target" is:

• Multiple patterns, small batches, and frequent changeovers: Single-color machines offer greater flexibility and faster setup.

• Long batches, high requirements for appearance consistency, and low tolerance for errors: Two-color machines, thanks to automatic color registration/servo synchronization and a two-layer-at-a-time cycle, offer greater stability.

3. If your "Budget and Space" is:

• Limited budget/limited space: Single-color machines have a shorter body (e.g., approximately 2200 × 2800 × 1700 mm).

• Investing in quality and efficiency: Two-color machines have a longer body (e.g., approximately 6000 × 2800 × 1700 mm listed on the page), but offer higher unit output completeness and yield.

Monochrome vs. Two-Color Wood Grain Printing Machines: Quality Evaluation

• Detail and Edge Sharpness: Observe the ratio of fine line burrs and broken lines under a magnifying glass;

• Graining and Image Fidelity: A subjective and objective assessment of grayscale steps and growth ring gradations;

• Registration Accuracy (Two-Color): Measure the relative displacement of adjacent color layers on a sample strip;

• Color Difference: ΔE (Same-Batch/Across-Shift Comparison);

• Abrasion and Chemical Resistance: Rubber Abrasion and Alcohol/MEK Wipe Tests;

• Repeatability: Comparing samples before and after printing for "texture drift/color shift" and yield statistics after a long printing period.

Back to the topic: Monochrome vs. Two-Color Wood Grain Printing Machines: What are the Core Differences?

• Monochrome Wood Grain Printing Machines—They offer a simpler structure and process chain, faster setup and changeover, and a lower barrier to purchase and use. They can render the main texture clearly and sharply, making them suitable for simple styles, basic decoration, cost-sensitive projects, and high-frequency changeovers.

Common capabilities include effective widths of 0–1320 mm, thicknesses of 2–80 mm, line speeds of 0–20 m/min, and a minimum length of approximately 300 mm. The machine is also more compact (e.g., approximately 2200 × 2800 × 1700 mm).

• Two-color wood grain printing machine: Featuring two units in tandem and fully servo/automatic color registration, this machine can achieve layered overprinting in a single pass, ensuring the depth of the "main grain + shadow/annual rings" image. This machine offers advantages in image fidelity, stable yield, and unit output integrity.

Typical specifications also cover widths of 0–1320 mm, thicknesses of 2–80 mm, line speeds of 0–20 m/min, and a minimum length of approximately 300 mm. However, the overall machine length is significantly longer (approximately 6000 × 2800 × 1700 mm). Key features include servo control, automatic balancing/color difference compensation, precise color placement, and "pattern fidelity ≥ 98%."

Decision in One Sentence:

• Need speed, clear main grain, and low cost/frequent changeovers? Choose a single-color wood grain printing machine.

• Need depth, image fidelity, and stable yield over long batches? Choose a two-color wood grain printing machine.

What products does Foshan XMF Machinery Co., Ltd. offer?

Foshan XMF Machinery is a leading manufacturer and supplier specializing in surface coating and printing equipment. Our product range includes roller coating machines, spray machines, printing machines, embossing machines, and UV curing machines designed for diverse materials such as wood, metal, plastic, and ceramics. We offer high-quality machines at competitive prices for wholesale and customized orders to meet various industrial demands.