Digital wood printing machines (also known as flatbed digital printing machines) differ fundamentally from conventional printing (referring to traditional plate-making processes such as gravure, flexographic printing, screen printing, heat transfer printing, transfer printing, or roll-to-roll printing) in terms of principles, processes, applicable scenarios, cost structure, color performance, and post-processing compatibility.

Below, I will break down the question into a series of sub-questions that readers are most concerned about and answer them one by one, covering technology, processes, quality, cost, and selection points to help you systematically determine "when to use a digital wood printing machine and when to use conventional printing."

What is a "digital wood printing machine"?

A digital wood printing machine generally refers to equipment that uses piezoelectric or thermal inkjet technology to directly print dot matrix images onto rigid or semi-rigid substrates such as wood, MDF, plywood, PVC-coated boards, and acrylic. The most common type is the UV flatbed digital printing machine, which uses UV-curing inks or other suitable digital inks, curing immediately after printing and directly outputting color, white background, varnish, and embossing effects.

What is "conventional printing"?

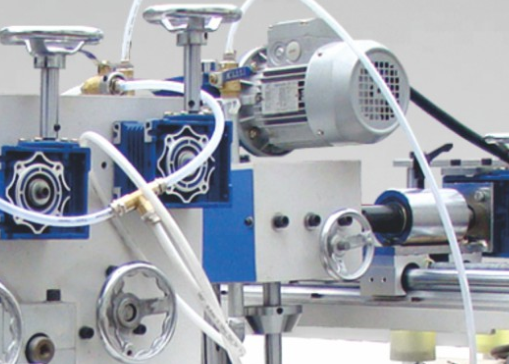

Conventional printing here refers broadly to traditional printing processes that require plate making or roller/stencil transfer, including gravure, flexo, screen printing, heat transfer/transfer printing, roll-to-roll printing, or roller-coated wood grain printing machines. These methods typically follow a "plate making—inking—transfer—drying" process, suitable for mass production of the same image.

Digital wood printing machine VS. Conventional: What are the differences in principle and process?

1. Digital wood printing machine

Digital files (TIFF/PSD/RAW) are processed by a ripper (RIP) and then the printhead sprays ink droplets onto the substrate; if it is UV ink, it is immediately cured by a UV lamp; printing is "pixel-by-pixel printing on demand," without the need for plate making. Short workflow: Design → RIP → Plate loading → Printing → Curing/finished product.

2. Conventional Printing

First, a printing plate (engraved, screen-printed, or roller-printed) is made, with the design printed on it. Then, ink is applied and transferred to the substrate via a squeegee, impression, or roller. Finally, it is cured using hot air/infrared/oven or UV. The process is lengthy: design → plate making → machine setup (proofing) → printing → drying → post-processing.

Result: Digitalization reduces pre-printing preparation time, but traditional printing still has an advantage in large-volume, single-variety printing due to its lower unit cost.

Color and Image Quality: Which is Better?

• Advantages of Digital Wood Printing Machines: Printheads can achieve high resolution (commonly 600–1200 dpi, some models even higher), controllable grayscale, smooth gradations using multi-dot size and micro-droplet mixing, support for overprinting white ink and transparent varnish, and easily produce realistic photo-quality wood grain or decorative patterns; digital printing also performs excellently in variable color data and small-batch variety. Color management is controlled via ICC/Profile and RIP, making customization easy.

• Advantages of Traditional Printing: Some traditional processes (such as gravure) exhibit stable performance in long, continuous textures and extremely high ink volume stability. Color saturation and coverage are further optimized for certain special pigments or metallic effects; however, dot gain and registration must be carefully managed. The color gamut of traditional printing is affected by ink type and plate-making precision.

Cost Structure: Which is more cost-effective?

• Digital Wood Printing Machine: Low initial cost (no plate-making required), but high ink costs, high investment per unit, and frequent maintenance (printheads, circulation system); suitable for small-batch, diversified, and on-demand printing. The marginal cost per unit tends to stabilize as the batch size increases.

• Traditional Printing: High plate-making and machine setup costs, but low unit printing cost once the volume is large (especially roll-to-roll gravure or flexographic printing, which has a significant cost advantage at the million-unit production scale). Traditional printing is more suitable for long-term orders with large batches of single patterns.

Judgment Criteria

If the batch size of a single item is small and requires rapid switching, customization, or multiple designs running concurrently, digital printing is generally more economical. However, if the batch size is over 10,000 sheets per design with high repetition rates, traditional printing becomes more cost-effective after amortizing plate-making costs.

Delivery Cycle: Which is Faster and More Flexible?

Digital wood printing machines have a clear advantage in delivery cycle: from design to shipment can be completed in hours to days; no waiting time for plate-making or lengthy proofing is required. More importantly, they support variable data printing (different patterns/numbers/QR codes for each item), suitable for personalized customization. Changing colors in traditional printing requires plate-making and lengthy machine adjustments, making frequent changes unsuitable.

Digital Wood Printing Machine VS. Traditional: Are Substrate Adaptability the Same?

• Digital wood printing machines are typically designed for flatbed printing, suitable for rigid or flat materials (such as MDF, plywood, melamine laminate, PVC board, acrylic, glass, etc.). Workpieces are fixed in place by vacuum or suction tables, limiting printing height (nozzle-to-surface distance). For parts with significant thickness variations or complex three-dimensional shapes, additional fixtures or step-by-step printing are required. UV inks adhere well to wood/veneers, but often require a primer or pretreatment to ensure adhesion and durability.

• Traditional printing (e.g., roller/roller wood grain coating machines) is better suited for continuous roll-to-roll and flatbed printing with rapid throughput. Screen printing performs better on irregular surfaces or thick ink layers, while heat transfer has a natural advantage for three-dimensional profile coating.

Therefore, substrate selection directly affects the type of equipment used: digital flatbed printing is preferred for flat, large boards, while traditional lines are still preferred for roll-to-roll and curved surfaces, high-volume flooring, or lamination processes.

How do durability and functionality (scuff resistance, chemical resistance, weather resistance) compare?

• Durability depends on the ink system and curing method. Digital wood printing machines are often equipped with UV-cured inks or special abrasion-resistant inks, resulting in a highly cross-linked, scrub-resistant, and chemically resistant film after curing; however, insufficient curing of white ink or thick ink layers can affect durability.

• Traditional printing utilizes highly practical solvent-based or thermosetting inks, followed by a topcoat/abrasion-resistant layer, exhibiting excellent long-term stability under both indoor and outdoor conditions. Overall results depend heavily on process formulation and post-treatment (such as topcoat, baking, or UV coating).

Production Efficiency vs. Capacity Comparison?

• Digital wood printing machine: Single-piece printing time is determined by resolution, color depth, number of white ink layers, and area. It is generally slower than traditional high-speed roller printing, suitable for small to medium batches and high-value-added products. Some high-speed flatbed machines achieve higher capacity through multiple printheads in parallel and automatic feeding, but overall, they still lag behind continuous gravure or flexographic lines in "very high-volume" applications.

• Conventional printing (roller/gravure): Designed for continuous operation, it can run stably at extremely high line speeds for extended periods, suitable for continuous roll-to-roll and large-volume sheet production around the clock.

Environmental Protection vs. Safety: Which is More Environmentally Friendly?

Environmental protection cannot be generalized; the key lies in the ink system and treatment equipment.

• Digital wood printing machine (UV ink): If using 100% solid UV ink, the VOCs during curing are extremely low, resulting in good environmental performance. However, attention must be paid to the UV light source (mercury lamp ozone, LED thermal management) and waste ink disposal.

• Solvent-based traditional printing: Solvent evaporation produces higher VOCs, requiring treatment such as RTO/activated carbon. Water-based technology has environmental advantages but places high demands on drying equipment.

Overall, production lines using UV or water-based technology with qualified treatment devices have lower environmental pressure; solvent-based traditional printing has higher environmental treatment costs.

Color Management and Process Stability: How do they differ in operational complexity?

• Digital wood printing machines are highly dependent on color management (ICC, RIP, gray balance, linearization). Operators need to have digital color management knowledge and manage printhead status, ink temperature and viscosity, white ink circulation strategies, layering, and clear varnish logic. The equipment can save process parameters through software for production replication, and its stability is high with proper maintenance.

• Traditional printing relies on consistent plate-making and inking systems for color stability, with operations heavily reliant on mechanical adjustments (squeegee, impression, dot control). While traditional printing offers superior repeatability on the same machine over the long term, plate changeovers and color matching are time-consuming and costly.

Both require strict process control and quality inspection, but digital printing emphasizes digital management, while traditional printing focuses on material and plate-making process control.

What scenarios are suitable for digital wood printing machines?

Typical scenarios for choosing a digital wood printing machine:

• Small to medium batch production, diverse product range, frequent product changes;

• Personalization, order-based changes (variable data);

• High-value-added products requiring high-resolution photo-quality printing or partial overprinting of white/gloss varnish;

• Short lead times and unacceptable plate-making time.

What scenarios are suitable for traditional printing?

Typical scenarios for choosing conventional printing (gravure/flexographic/heat transfer/screen printing/roller printing):

• Large-volume production of a single pattern (tens of thousands, hundreds of thousands or more) to reduce plate-making costs;

• Processes requiring special pigments (such as metallic paint, thick-layer screen coating) or high coverage;

• Continuous roll-to-roll production (flooring, film, packaging rolls) requiring extremely high line speeds.

Digital wood printing machine VS. Conventional: What are the differences?

—In short: Digital wood printing machines offer core values of "plate-free, on-demand, high-definition, and variable," suitable for flexible, small-batch, and high-value-added scenarios; while conventional printing features "reduced plate-making costs, continuous high output, and strong adaptability to special inks," suitable for large-volume, standardized production.

The two are not complete substitutes, but rather complementary: choosing the most suitable process based on product attributes, output, cost, and delivery time requirements is a rational engineering decision.