When we talk about the industrial mass production of "wood grain effects," many people first think of "applying wood grain paper" or "spray painting with textured finishes."

In fact, in modern surface decoration production lines, "Wood Grain Printing Machines" are a well-defined and multi-branched family of equipment: they include traditional gravure roller printing, digital UV inkjet printing, and even extend to complete sets of equipment for "transferring" wood grain patterns from the printing medium to the substrate surface, such as heat transfer and water transfer printing.

To clearly explain the "types of Wood Grain Printing Machines," we must simultaneously describe them from four dimensions: printing principles, substrate form, color group structure and registration method, and curing/drying method. We must also consider the upstream and downstream assembly of the production line process (pretreatment → printing → varnishing/coating → curing → inspection) to examine their respective applicable boundaries and differences.

What is a "Wood Grain Printing Machine"?

A "Wood Grain Printing Machine" is a specialized device and process system for stably and repeatedly transferring/printing wood grain patterns onto a substrate surface. The "machine" here typically includes not only a main unit but also:

• Feeding/conveying/positioning devices;

• Imaging and inking units (e.g., gravure anilox rollers, inkjet arrays, transfer film hot pressing units, or water transfer impregnation tanks);

• Registration and color group control systems (mechanical gears or electronic shafts, vision registration);

• Curing/drying modules (UV mercury lamps or UV-LEDs, hot air/IR, heated hot pressing, etc.);

• Rewinding/unloading and online inspection (color difference, gloss, surface defects).

The classification of "Wood Grain Printing Machines" can be understood along four main axes:

A. Printing/Transfer Principle;

B. Substrate Form (Sheet, Roll, Profile/Line, 3D Curved Surface);

C. Color Groups and Registration (Single Color, Two Color, Multicolor; Mechanical/Electronic Axis/Visual);

D. Curing Method (UV/Hot Air/Hot Press/Room Temperature Drying). These will be discussed in detail below.

What are the types of Wood Grain Printing Machines?

Main types of Wood Grain Printing Machines classified by "Printing/Transfer Principle":

1. Grain Roller Wood Grain Printing Machine

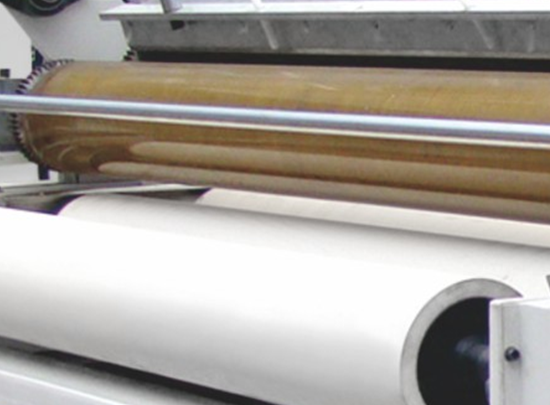

The wood grain pattern is engraved on the surface of a gravure copper/steel roller, with ink stored in cells; a doctor blade controls the remaining ink, and then the ink is transferred from the cells to the substrate through contact printing (or first transferred to a soft PU transfer roller before being applied to the substrate).

The industry commonly sees monochrome/two-color/multi-color gravure wood grain printing machines, as well as multi-color gravure lines for edge banding strips, and specialized unit configurations for PVC windows/profiles. Many manufacturers' product catalogs include branches such as "monochrome/two-color wood grain printing machine," "edge banding UV printing machine," and "board UV flatbed printing machine," reflecting the engineered adaptation to different substrate forms based on this principle.

• Features: Continuous, stable, high-speed: Suitable for long-batch production and high color consistency scenarios.

• Layering: Cell depth and shape determine the depth, detail, and fullness of the texture; can perform monochrome/two-color/multi-color overprinting.

• Ink System: Solvent-based and UV-curable inks are both acceptable; UV systems can be connected to downstream "wood UV dryers/UV curing modules" for immediate curing.

• Typical Applications: Boards (MDF, PVC boards, melamine finish bases, etc.), edge banding rolls, PVC/aluminum alloy profile surfaces, baseboards/door frame moldings, etc.

2. Digital UV Inkjet Wood Grain Printing Machine

This machine directly sprays CMYK (often with white ink and varnish) onto the substrate surface using an inkjet array (droplet-on-demand), followed by UV-LED/mercury lamp curing.

Features include RIP color management, electrostatic/corona/flame treatment, a matching UV curing module, and online color difference/gloss monitoring. Many manufacturers market it under names like "UV Board Digital Flatbed Color Printer," specifically for direct printing of wood grain on door panels, cabinet panels, etc.

Key Features:

• Plate-free: Flexible pattern changes, significant advantages for small-batch, diverse production.

• High resolution and grayscale: Digital halftone rendering of wood grain transitions, knots, and contour layers.

• Customizable working area: Flatbed printers are suitable for door panels/flooring, roll-to-roll printers are suitable for films and roll materials, and multi-faceted direct printing structures for profiles are also available (equipped with multi-array/following fixtures).

• White ink/varnish: Applys a base coat and surface clear coat to white/dark substrates, enhancing coverage and wear resistance. • Applicable Substrates: Wood, MDF, PVC, ABS, glass, metal substrates, etc., after surface energy and adhesion treatment.

3. Wood Grain Printing Machine

The wood grain pattern is pre-printed onto heat transfer paper/film, and then the pigments/dyes are sublimated/penetrated/adhered to the substrate surface through heat pressing + time + pressure. For metals (such as aluminum profiles), the common process is: powder coating of the base color → covering with wood grain transfer paper → vacuum/heat pressing sublimation → peeling off the paper base to obtain a stable wood grain appearance.

Features and Limitations:

• Extremely mature for aluminum profile doors, windows/curtain wall profiles, etc.;

• Requires a pre-coated/powder undercoat to ensure pattern color development and adhesion;

• Suitable for mass production of the same pattern on profiles, pipes, and other regular geometric parts.

4. Water Transfer Wood Grain Printing System

A soluble printing film is placed on a water surface. After activation, the wood grain pattern is suspended as a thin film. The workpiece is immersed in the film, allowing the pattern to adhere to the three-dimensional curved surface. It is then cleaned, dried, and coated with a clear varnish.

• Applicability: Highly suitable for complex three-dimensional curved surfaces (handles, decorative parts, curved shells), and is a standard route for "wood grain on three-dimensional parts".

• Boundary Conditions: Requires high process control for pattern continuity and batch-to-batch consistency; it is not a traditional "roller direct printing", but it is one of the commonly used wood grain transfer systems for industrial wood grain appearance.

5. Screen Printing for Woodgrain

This system transfers wood grain ink locally or over the entire substrate using a screen. It is suitable for thick ink layers, high opacity, or localized texture effects.

• Features: Relatively simple plate making, suitable for partial decoration, special effects (such as coarse textures), and small-format repetitive patterns; however, it is inferior to gravure and inkjet printing in terms of delicate gradations and high-speed printing of long formats.

6. Coating & Wiping/Embossing + Printing Wood Grain Printing Machine

Strictly speaking, it leans towards coating/texturing equipment: first, a roller coating is applied as a base, then a texture roller/wiping roller is used to apply color or create texture on the raised areas. If necessary, overprinting or clearing is added to form a visual and tactile wood grain. It overlaps with gravure printing (both use texture rollers), but is more often considered a wood grain effect unit in coating lines.

• Advantages and limitations: Strong three-dimensional texture and high efficiency, but the freedom of color and the subtlety of the layers are weaker than digital inkjet printing. The level of detail and realism is usually determined by the quality of the engraving roller and the ink flow.

How to choose the type of "Wood Grain Printing Machine" according to the scenario?

1. Production Volume and Pattern Structure

• Large-volume, limited patterns, long-term stability: Prefer gravure roller printing or heat transfer printing (profiles);

• Small-batch, diverse, customized, rapid pattern changes: Prefer digital UV inkjet printing (flatbed/profiles) or hybrid processes (pre-printing + digital touch-up).

2. Substrate Forms

• Mainly sheet materials: Gravure flatbed direct printing or UV flatbed digital printing;

• Roll-to-roll/edge sealing strips: Multi-color gravure roll-to-roll printing (with UV coating and curing);

• Profiles/lines: Multi-sided gravure direct printing or heat transfer sublimation (classic route for metal profiles);

• Complex 3D parts: Water transfer printing.

3. Target Appearance and Tactile Feel

• Realistic texture and layering: Multi-color gravure or digital inkjet printing;

• Three-dimensional tactile feel: Embossing/roller coating + color rubbing synergy, overprinting and clearing when necessary.

4. Overall Cost and Environmental Impact

• Weak VOC and solvent recovery capabilities: Prioritize UV systems (gravure UV or inkjet UV);

• Controllable energy/thermal management and paper film consumption: Heat transfer printing is more mature and stable on profiles.

5. Process Support and Maintenance

• Does the company have UV curing equipment and color management capabilities?

• Can it quickly change patterns/lines (electronic axis, vision registration, quick roll/quick template change)?

• Are the tooling fixtures and upstream sanding, dust removal, and corona treatment conditions adequate?

Common Technical Misconceptions and Boundary Clarifications

“Can any substrate be directly UV coated?”

No. Low surface energy plastics require corona/flame coating or a primer; metal profiles often use powder base color before heat transfer/direct printing.

“More colors mean more realism?”

Multiple colors can indeed expand the color gamut, but the quality of the engraved/inkjet original image, registration, and varnish system also determine the “wooden texture.”

“Is gravure always clearer than digital?”

With high-quality printheads and precise ripping, digital printing can create extremely fine texture gradients; however, for high-volume production, gravure printing still excels in terms of speed and unit cost.

"Is heat transfer just applying a film?"

It's essentially sublimation/diffusion or thermal adhesion, not simply pasting a sticker; durability depends on the substrate, film material, and heat-pressing parameters.

"Is water transfer suitable for any part?"

It's uneconomical for long profiles and large sheets, and requires specific wastewater/activator treatment.

What kind of promotions does XMF Machinery offer?

We regularly launch promotional campaigns for selected coating machines, offering discounts and special wholesale prices. Buyers can take advantage of seasonal promotions to purchase high-quality machines at reduced costs. Our sales team provides updated quotes and details about current offers, ensuring you don't miss opportunities to buy at the best possible price.