In modern manufacturing, CNC automatic spraying machines have become essential equipment in surface coating processes due to their high precision, high efficiency, and consistency. Compared to traditional manual spraying methods, they significantly improve coating quality, reduce labor costs, minimize material waste, and ensure consistent product appearance.

However, different production scenarios and material requirements often necessitate the selection of different types of coatings. So, what types of coatings can a CNC automatic spraying machine actually spray? This article will systematically answer this question from the perspectives of technical principles, coating characteristics, and application compatibility.

Basic Principles and Spraying Methods of CNC Automatic Spraying Machines

A CNC automatic spraying machine (Computer Numerical Control Coating Machine) is an automated device that uses a computer program to control the spraying trajectory and parameters. Its core lies in precisely controlling the movement of the spray gun, spraying speed, spray width, air pressure, and flow rate through a numerical control system, thereby achieving a stable and uniform spraying effect.

Common spraying methods for CNC automatic spraying machines include:

• Air Spray: Atomizes paint using compressed air, suitable for fine surfaces and thin-layer coatings.

• Airless Spray: Directly atomizes paint using a high-pressure pump, producing a thicker layer, suitable for anti-corrosion or thick-film coatings.

• Electrostatic Spray: Improves paint adhesion using electrostatic adsorption, commonly used on metal surfaces.

• Thermal/Powder Coating: Achieves adhesion and melting of solid powder using heating or electrostatic adsorption.

Due to the high programmability of CNC automatic spraying machines, they are compatible with various spraying methods, thus adapting to the needs of various types of paints.

What types of paints can a CNC automatic spraying machine spray?

Depending on the chemical composition and application of the paint, CNC automatic spraying machines are suitable for various liquid and powder paints. The following are the main classifications and compatibility descriptions.

1. Water-based Coatings

Water-based coatings are environmentally friendly coatings that use water as the dispersion medium. They offer advantages such as low VOC (volatile organic compound) emissions, safety, odorlessness, and easy cleaning.

CNC automatic spraying machines have excellent compatibility with water-based coatings, and are widely used, especially in wood, plastics, electronic product casings, and automotive interior parts.

Common types of water-based coatings include:

• Acrylic water-based coatings: Strong weather resistance and good adhesion, suitable for spraying plastic and metal parts;

• Polyurethane water-based coatings: Excellent abrasion resistance and flexibility;

• Epoxy water-based coatings: Used in industrial corrosion protection.

CNC automatic spraying machines, through precise control of spraying pressure and atomization, effectively avoid common problems with water-based coatings such as sagging and orange peel.

2. Solvent-based Coatings

Solvent-based coatings use organic solvents as the dispersion medium and are characterized by fast drying speed, high gloss, and strong adhesion.

Despite increasingly stringent environmental regulations, solvent-based coatings still hold an important position in some industrial manufacturing processes. CNC automatic spraying machines can efficiently and stably spray these coatings, making them particularly suitable for products with extremely high requirements for coating appearance.

Suitable solvent-based coatings include:

• Nitrocellulose lacquer (NC Paint): Fast drying, easy application;

• Polyurethane lacquer (PU Paint): High abrasion resistance and decorative properties;

• Amino baking varnish: Used for the surfaces of household appliances and machinery parts;

• Acrylic lacquer: High transparency and good color retention.

Through the precise airflow and atomization control of CNC automatic spraying machines, overspray and bubbles in solvent-based coatings can be reduced, improving surface smoothness and gloss.

3. Powder Coating

Powder coating is a solvent-free solid coating that forms a coating through electrostatic adsorption and high-temperature curing. It has advantages such as strong chemical resistance, good adhesion, and no pollution.

CNC automatic spraying machines can be equipped with dedicated electrostatic spray guns to achieve automated powder coating, commonly used in metal casings, aluminum profiles, household appliances, furniture, and other fields. Common types of powder coatings include:

• Epoxy powder coatings: Suitable for anti-corrosion and anti-static applications;

• Polyester powder coatings: Excellent weather resistance;

• Epoxy-polyester hybrid powder coatings: Combining the advantages of both, widely used in the casings of home appliances and office equipment.

When using a CNC automatic spraying machine, the stability of the electrostatic system, airflow distribution, and workpiece grounding are key factors. The equipment uses a CNC system to precisely adjust the spray distance and speed, ensuring consistent powder coating thickness.

4. UV-cured coatings

UV-cured coatings use photosensitive resins as the main film-forming substance and require UV irradiation for curing. They offer extremely fast curing speeds and excellent environmental performance.

CNC automatic spraying machines can be used in conjunction with UV curing lines to achieve integrated coating and curing operations. They are mainly used on high-gloss product surfaces such as wood, plastics, mobile phone cases, optical components, and decorative panels.

Features include:

• Rapid film formation, improving production cycle time;

• High coating hardness and scratch resistance;

• Suitable for mirror finishes and high-gloss products.

Due to the high fluidity and viscosity of UV coatings, CNC automatic spraying machines can adjust the nozzle diameter and spraying angle to achieve a more uniform coating distribution, avoiding localized accumulation or thin coatings.

5. Metallic/Conductive Coatings

Metallic coatings contain metal powders (such as aluminum powder, copper powder, nickel powder, etc.), which can impart a metallic texture or conductive properties to products.

CNC automatic spraying machines, through precise control of the coating atomization particle size and spraying direction, can prevent uneven metal particle settling, improving coating density and conductivity.

Applications include:

• Electroplating alternative metallic paint: used on plastic parts surfaces;

• Conductive coating: used for anti-static coatings on electronic component housings;

• Reflective coating: used on signage, lighting fixtures, and other products.

CNC automatic spraying machines offer extremely high repeatability, enabling multi-layer spraying of metallic coatings to achieve specific gloss or conductive effects.

6. Special Functional Coatings

Besides conventional decorative and protective applications, CNC automatic spraying machines can also spray a variety of special functional coatings, including:

• Anti-fingerprint coating (AF Coating): Commonly used on the glass surfaces of mobile phones and tablets;

• Antibacterial coating: Used in medical devices and public facilities;

• Antistatic coating: Suitable for electronic device casings;

• High-temperature resistant coating: Used in engine, oven components, etc.;

• Self-cleaning coating: Surface protective layers containing photocatalytic materials.

These coatings often require extremely high uniformity and film thickness control. Thanks to its numerical control precision and visual programming system, the CNC automatic spraying machine can achieve micron-level film thickness control, ensuring consistent performance for each coating layer.

How adaptable is the CNC automatic spraying machine to different materials?

The CNC automatic spraying machine can not only spray a variety of coatings but also adjust spraying parameters according to different substrates. Commonly compatible materials include:

• Metals: such as steel, aluminum, and magnesium alloys, often used with solvent-based paints, powder coatings, or metallic paints;

• Plastics: such as ABS, PC, and PP, mostly using water-based or UV paints;

• Wood: such as solid wood and MDF, suitable for water-based or UV coatings;

• Glass and ceramics: can use UV or functional coatings.

The equipment can automatically adjust the spray distance, air pressure, and gun speed according to the material to ensure coating adhesion and smoothness on different substrates.

Can a CNC automatic spraying machine switch between multiple coatings?

Many manufacturing companies need to spray multiple different types of coatings on the same production line.

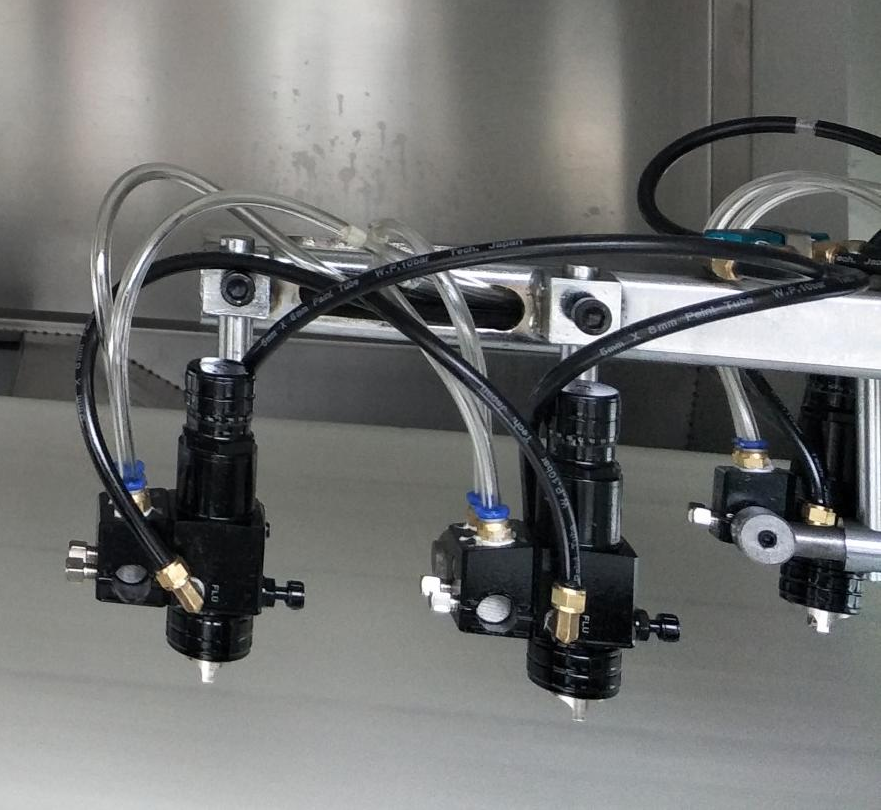

CNC automatic spraying machines typically have multiple paint supply systems, which can automatically switch between paint pipelines and spray guns through program control. Common switching methods include:

• Multi-pipeline parallel design;

• Automatic cleaning and purging system;

• Quick color change module.

These designs allow the equipment to quickly switch between different types of coatings, avoiding cross-contamination and ensuring spraying accuracy and consistency.

What precautions should be taken when using a CNC automatic spraying machine to spray different coatings?

Different types of coatings have different requirements for equipment and process parameters during spraying. The following are key considerations:

• Nozzle selection: Water-based and solvent-based paints have different viscosities, requiring matching nozzles of appropriate diameters.

• Air pressure and flow control: Too high a pressure will cause overspray, while too low a pressure will result in insufficient atomization.

• Coating filtration: Prevent impurities from clogging the nozzles.

• Static grounding: Powder coatings require proper workpiece grounding.

• Curing conditions: UV coatings require precise control of light intensity and exposure time.

• Equipment cleaning: Regularly clean the paint supply lines to prevent color mixing or skinning.

CNC automatic spraying machines are typically equipped with automatic cleaning systems and intelligent monitoring functions, which can detect spraying parameters in real time to ensure stable production.

Can a CNC automatic spraying machine meet high-precision spraying requirements?

The answer is yes.

The advantages of CNC automatic spraying machines lie in their high repeatability, programmable trajectory, and excellent coating uniformity.

Through CNC programming, the equipment can maintain a constant spray distance and angle on complex curved surfaces, ensuring consistent coating thickness across all areas. Furthermore, with a closed-loop control and sensor feedback system, spraying errors can be corrected in real time, meeting the stringent surface quality requirements of high-end products.