In the wood processing industry chain, plywood has become a core material in building materials, furniture, and decoration due to its wide application, excellent performance, and diverse specifications.

In the plywood production process, surface treatment is always one of the key steps determining the quality of the finished product.

Choosing the most suitable industrial sanding machine for plywood directly affects the flatness, smoothness, and suitability for subsequent processing.

This article, titled "What is the most suitable industrial sanding machine for plywood?", will delve into this question to help readers understand the importance of industrial sanding machines in plywood processing and the selection criteria.

The Inevitable Need for Plywood Production and Surface Treatment

Plywood is a multi-layered board made of layers of veneers glued together. Its surface often has a certain degree of roughness, glue marks, thickness variations, and wavy patterns. If it enters the furniture manufacturing or decoration process directly without treatment, it can easily affect the finishing effect and even cause problems such as weak adhesion.

After the forming process, plywood must be surface-polished using an industrial sanding machine to achieve the following goals:

• Uniform thickness accuracy: Uneven thickness can occur in plywood after hot pressing. An industrial sanding machine effectively smooths the surface, ensuring dimensional consistency.

• Smooth and even surface: Burrs and roughness on the plywood surface are eliminated through belt sanding or grinding wheels.

• Improved processing adaptability: A high-quality sanded surface provides an ideal foundation for subsequent painting, veneering, and laminating processes.

Therefore, for plywood, an industrial sanding machine is not only essential equipment for improving surface quality but also a crucial guarantee for achieving high-standard finished products.

Industrial Sanding Machine: How Does It Work?

To understand the most suitable industrial sanding machine for plywood, we must first understand its working principle. The core of an industrial sanding machine lies in the coordinated operation of the belt sanding system and the pressure device.

Its basic operating mechanism is as follows:

• High-speed sanding belt operation: The industrial sanding machine uses a motor to drive the sanding belt, continuously grinding the board at a stable and efficient linear speed.

• Pressure roller pressing: Under the push of the feeding device, the board is tightly pressed against the sanding belt by pressure rollers or air cushion devices, thus achieving uniform sanding.

• Segmented cutting and layer-by-layer correction: The industrial sanding machine can be set with coarse and fine sanding stations as needed, first removing larger thickness deviations, and then performing fine polishing.

This principle ensures that the plywood processed by the sanding machine maintains both uniform thickness and a smooth surface.

Industrial Sanding Machine: Main Types and Characteristics

In plywood processing, different types of industrial sanding machines correspond to different application scenarios. Common types mainly include the following:

1. Wide-belt industrial sanding machine

This is the most common equipment for plywood processing. Its characteristic is a large sanding belt width, suitable for large-format boards. Advantages include:

• High processing efficiency, capable of covering the entire plywood surface in one pass;

• Combined coarse and fine sanding functions, suitable for mass production;

• Effective control of thickness deviation, meeting industrial standards.

2. Thickness-Fixing Industrial Sanding Machine

This type of sanding machine focuses on thickness correction and is typically used for the initial sanding of plywood. Its features include:

• Large removal allowance, suitable for correcting uneven thickness;

• High processing speed, ensuring dimensional accuracy;

• Suitable for large-volume plywood thickness-fixing processing.

3. Precision Polishing Industrial Sanding Machine

Primarily used for the fine finishing of plywood surfaces. Its advantages are:

• Low surface roughness, improving gloss;

• Suitable for finishing processes before coating and lamination;

• Ensures the visual appeal and smooth feel of the finished product.

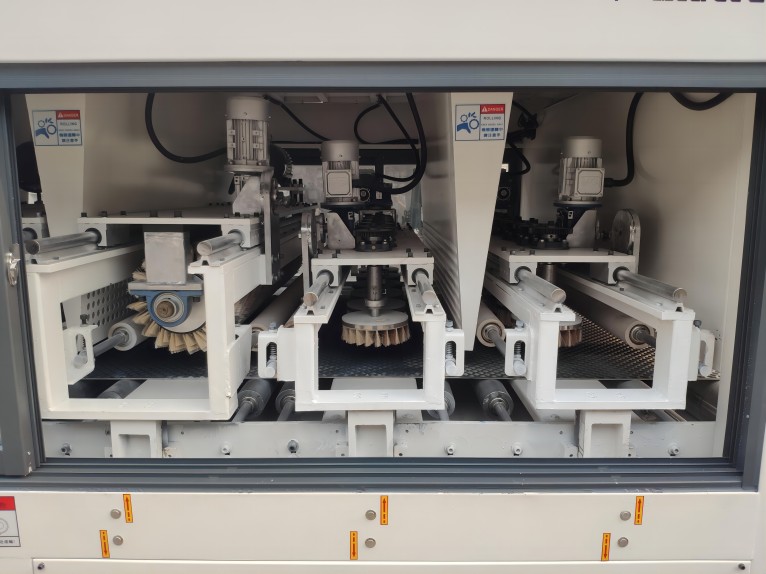

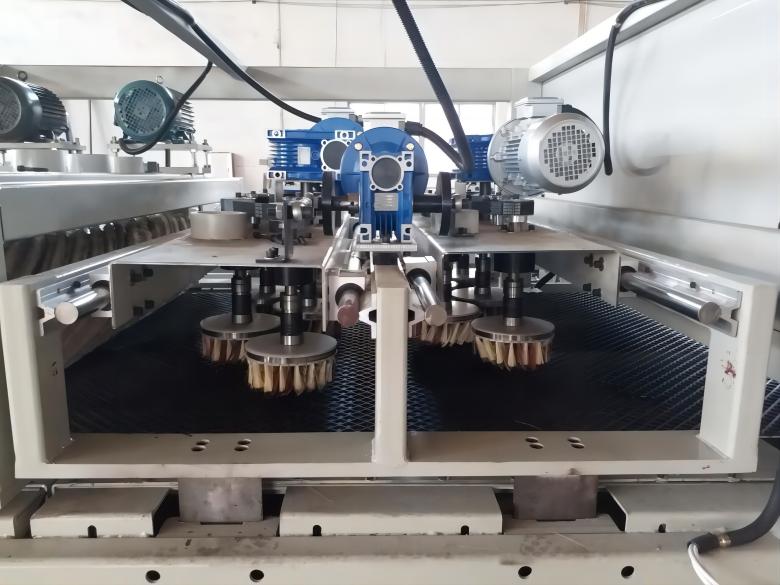

4. Modular Industrial Sanding Machines

These machines integrate thickness setting and polishing functions, featuring multi-station combinations to achieve "one-pass, multiple processing" of plywood. Features include:

• High process integration, improving production line efficiency;

• Meeting the surface treatment needs of different plywoods;

• Suitable for integrated production lines with multiple specifications and requirements.

In summary, different types of industrial sanding machines have different focuses in plywood processing, and the most suitable choice depends on production goals and quality requirements.

Key to Industrial Sanding Machine Adaptation for Plywood

To scientifically answer "What is the most suitable industrial sanding machine for plywood?", clear judgment criteria must be established. The following indicators are the core basis for equipment selection:

1. Sanding Belt Width and Length

Plywood has a large surface area, so the sanding belt width of the industrial sanding machine must be sufficient to cover the entire board; otherwise, uneven sanding will occur. Wide-belt sanding machines have an advantage in this regard.

2. Feed Speed and Belt Speed

Appropriate feed speed and belt speed determine processing efficiency and surface quality. Too fast a speed will affect the finish, while too slow a speed will result in low efficiency. The optimal solution is an adjustable-speed industrial sanding machine.

3. Pressure Control System

Plywood materials vary, with different hardness levels. The pressure device of the industrial sanding machine must have flexible adjustment capabilities to ensure uniform pressure application in different areas, avoiding indentations or insufficient sanding.

4. Dust Removal System Efficiency

The sanding process of plywood generates a large amount of dust. Inadequate dust removal will affect processing quality and environmental safety. Therefore, an efficient dust removal system is an essential requirement for industrial sanding machines suitable for plywood.

5. Thickness Control Accuracy

The thickness error of plywood must be controlled within a strict range. An industrial sanding machine with high-precision automatic thickness measurement capabilities can better meet production needs.

6. Stability and Durability

Long-term batch operations place high demands on the structural stability and wear resistance of industrial sanding machines. A high-rigidity frame and a high-quality transmission system are crucial for ensuring equipment is suitable for plywood processing.

The Value of Industrial Sanding Machines in Plywood Processing

Suitable industrial sanding machines for plywood are valued not only for their operational aspects but also for their production impact:

• Improved Finished Product Grade: High-quality surface-treated plywood significantly enhances market competitiveness;

• Reduced Rework Rate: High-quality sanding reduces surface defects and avoids secondary processing;

• Guaranteed Production Consistency: Industrial sanding machines achieve stability in mass production through automation;

• Enhanced Adaptability: Whether in furniture manufacturing or construction, high-quality sanded plywood can seamlessly integrate with various processes.

What is the Most Suitable Industrial Sanding Machine for Plywood?

Based on the above analysis, it is clear that wide-band industrial sanding machines and modular industrial sanding machines are the most suitable for plywood surface processing. The reasons are as follows:

1. Wide-band industrial sanding machines can meet the uniform processing requirements of large-format plywood, ensuring thickness accuracy and overall flatness;

2. Modular industrial sanding machines integrate thickness setting and fine sanding functions, completing coarse sanding and polishing in a single pass, balancing efficiency and quality;

3. Both types feature flexible feed speed, pressure adjustment, and efficient dust removal systems, fully meeting the characteristics and requirements of plywood production.

Therefore, in practical selection, these two types of industrial sanding machines should be given priority, and a reasonable configuration should be made based on the specific production scale, quality standards, and budget.

What services can international buyers expect from XMF Machinery?

International buyers benefit from comprehensive services including product consultation, customized quotes, factory-direct pricing, shipping coordination, and ongoing after-sales support. We supply machines worldwide, offering competitive prices that attract buyers seeking affordable yet high-quality coating equipment from a reliable Chinese factory brand.