In modern furniture, wooden door, decorative panel, metal parts, and plastic product coating production lines, reciprocating automatic painting machines have become crucial equipment for improving coating efficiency and enhancing paint film consistency.

Compared to traditional manual painting methods, reciprocating automatic painting machines use robotic arms or sliding rail systems to achieve the back-and-forth movement of the spray gun, resulting in a more uniform coating distribution and more controllable thickness.

However, in actual production, many factory technicians raise a key question:

"What is the maximum coating thickness of a reciprocating automatic spraying machine?"

This question not only affects the surface quality of the product but also directly relates to paint consumption, drying speed, energy consumption, and subsequent curing processes.

This article will systematically analyze the maximum coating thickness of a reciprocating automatic spraying machine and its reasonable control methods from multiple perspectives, including spraying principles, influencing factors, control parameters, thickness detection, and optimization methods.

What is a reciprocating automatic painting machine? Why is coating thickness so important?

A reciprocating automatic painting machine is a spraying device that uses an automatic control system to drive a spray gun in a reciprocating motion.

The equipment typically consists of the following core components:

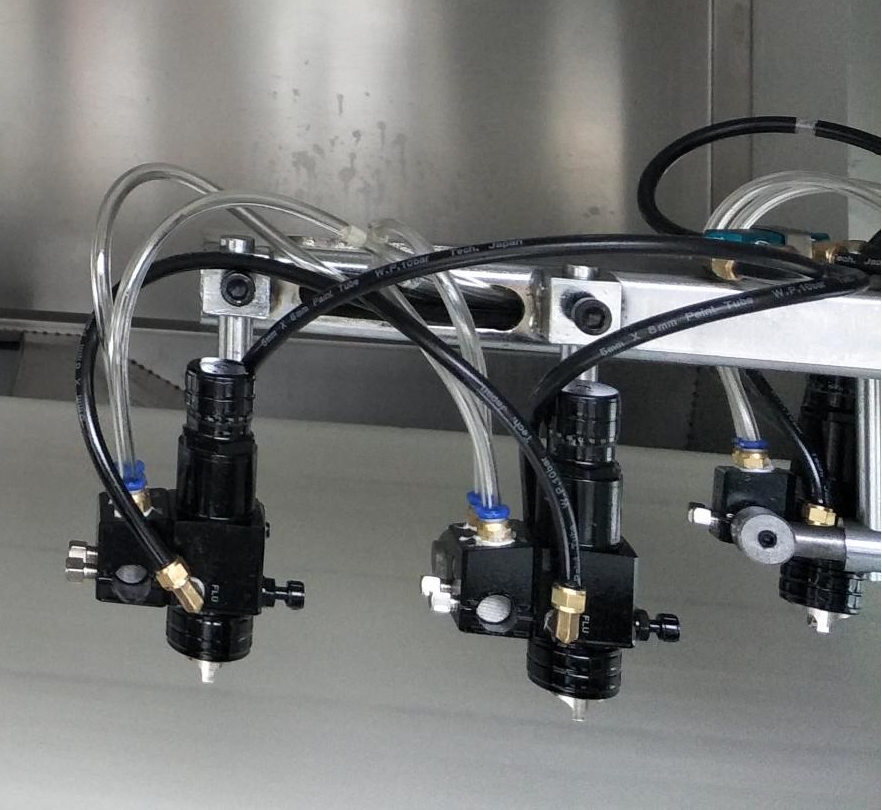

• Spraying mechanism (spray gun system);

• Reciprocating motion mechanism (motor-driven beam or robotic arm);

• Conveying system (belt or chain conveyor);

• Control system (PLC or touchscreen programming system);

• Paint mist treatment and recovery device.

When using a reciprocating automatic painting machine, coating thickness is one of the most critical process parameters. It directly determines the following factors:

• Coating adhesion and surface hardness;

• Gloss and smoothness;

• Paint drying time and energy consumption;

• Paint consumption and painting cost.

Excessively thick coatings may lead to sagging, bubbling, or incomplete drying; too thin coatings will affect hiding power and protective performance.

Therefore, defining the maximum coating thickness range for a reciprocating automatic painting machine is crucial for developing scientific process specifications.

How is the coating thickness formed in a reciprocating automatic spraying machine?

To understand coating thickness, it's essential to understand the spraying principle of a reciprocating automatic spraying machine.

During operation, the workpiece enters the spraying area via a conveyor belt. The spray gun moves back and forth along a set trajectory, atomizing the paint using compressed air or a high-pressure pump and spraying it onto the workpiece surface.

The coating thickness is primarily determined by three physical variables:

• Spray volume (paint flow rate): The volume of paint output by the spray gun per unit time;

• Spraying speed (spray gun reciprocating frequency/conveyor speed): The linear velocity of the spray gun relative to the workpiece;

• Number of sprays (overlap rate): The number of times the same location is sprayed and the overlap ratio.

The formula approximates this as:

Coating thickness ≈ (Spray flow rate × Coverage rate) ÷ (Spraying area × Spraying speed)

Therefore, the spray gun flow rate setting, reciprocating speed, and spray overlap are the core elements determining the coating thickness of a reciprocating automatic painting machine.

What is the maximum coating thickness of a reciprocating automatic painting machine?

Based on industry experience and standard equipment parameters, the single-pass coating thickness of a reciprocating automatic painting machine under standard operating conditions is typically between:

20μm and 60μm (i.e., 0.02 to 0.06mm).

However, the maximum achievable coating thickness depends on the type of paint and the spray gun configuration, as follows:

Coating Types | Recommended single-layer thickness (μm) | Maximum sprayable thickness (μm) | Notes |

| UV Curing Paint | 20–40 | 60 | Requires high-intensity UV drying |

| PU Polyurethane Paint | 25–50 | 80 | Can be applied in multiple layers for cumulative thickness |

| PE Unsaturated Polyester Paint | 40–80 | 120 | High viscosity, requires slow spraying speed |

| NC Nitrocellulose Paint | 15–30 | 40 | Fast drying, thin layers are preferred |

| Water-based Paint | 20–40 | 60 | Requires high-pressure atomization for stability |

Therefore, the maximum coating thickness of a reciprocating automatic spraying machine is generally around 80μm. For high-viscosity PE paint systems, a single-layer thickness of approximately 120μm can be achieved through low-speed spraying and staged drying.

Why do different paints have different maximum coating thicknesses?

The differences in the physical and chemical properties of different paint systems directly affect their film-forming ability and thickness stability during the spraying process.

1. Solvent-based paints

Solvent-based paints (such as PU paints and NC paints) have relatively low solid content. After solvent evaporation, the film thickness decreases significantly, therefore the actual film thickness is usually lower.

2. UV-cured paint

UV paints do not rely on solvent evaporation but form a film through light curing, thus achieving high thickness stability.

However, if the thickness is too thick, it can lead to incomplete internal curing, affecting surface hardness and adhesion.

3. Water-based paint

Due to their high surface tension, water-based paints are prone to pinholes and sagging if sprayed too thickly.

When spraying water-based paints with a reciprocating automatic painting machine, the thickness is typically controlled to within 40μm.

4. High-solids PE paint

PE paints are characterized by high viscosity and high solids content, allowing for thick film layers in a single application, but requiring a longer drying time and curing energy.

Therefore, the optimal spray thickness range varies significantly among different coating systems, and must be set appropriately according to the type of paint when using a reciprocating automatic painting machine.

What factors mainly affect the spray thickness of a reciprocating automatic spraying machine?

The thickness of a coating is not a fixed value; it is influenced by a combination of equipment and process parameters:

1. Spray gun flow rate and atomization pressure

A higher flow rate results in more paint being sprayed, leading to a thicker film.

Higher atomization pressure results in smaller atomized particles, providing more uniform coverage but reducing film thickness.

Therefore, low-pressure, high-flow-rate spraying is often used to control thick-film coating.

2. Spraying speed

If the spray gun moves too fast, the paint mist residence time is short, resulting in a thinner film.

If the spray gun moves too slowly, paint accumulates, increasing film thickness but increasing the risk of sagging.

Generally, the spray gun movement speed of a reciprocating automatic spraying machine is set between 0.5 and 1.5 m/s, and different thicknesses can be achieved through adjustment.

3. Spray overlap rate

A higher spray overlap rate results in a thicker film; however, efficiency decreases if it exceeds 70%.

The standard recommended overlap rate is 40%–60%.

4. Spray distance

The distance between the spray gun and the workpiece surface is generally 200–300 mm. Too close a spray distance can cause paint buildup, while too far a spray distance results in uneven thickness.

5. Conveyor Belt Speed

Improper matching of conveyor belt speed with the spray gun's reciprocating rhythm can cause uneven thickness in certain areas.

Generally, the speed should be controlled between 3 and 6 m/min.

How to detect and control the coating thickness of a reciprocating automatic painting machine?

To ensure that the coating thickness meets process standards, the following detection and control methods are typically used:

1. Wet Film Thickness Gauge

Measure the wet film thickness immediately after coating and convert it to dry film thickness.

Commonly used for daily process monitoring.

2. Dry Film Thickness Gauge

Measure the coating thickness after drying or curing.

Magnetic induction or eddy current type equipment is the most common.

3. Automatic Thickness Control System

Some high-end reciprocating automatic painting machines integrate a coating feedback system, which uses visual or laser scanning to detect the spray volume in real time, automatically correcting the spray gun output to maintain stable thickness.

Through proper detection and closed-loop control, reciprocating automatic spraying machines can achieve thickness accuracy control within ±5μm.

How to achieve thick film spraying on a reciprocating automatic painting machine?

For processes requiring thicker coatings (such as sealing primers or filler coats), the following methods can be used:

• Reduce the spray gun's travel speed (appropriately extend the dwell time);

• Adjust the nozzle diameter (select a 1.5–2.0mm large-diameter nozzle);

• Increase the spray gun flow rate (increase the paint supply pressure within a controllable range);

• Set up multiple reciprocating spraying programs (layer spraying, segmented drying);

• Adjust the conveyor speed and workpiece spacing (avoid paint mist turbulence).

With proper adjustments, reciprocating automatic painting machines can achieve single-layer thicknesses exceeding 80μm and cumulative multi-layer thicknesses exceeding 150μm, while maintaining good surface uniformity.

What issues need to be considered during thick film spraying?

In thick film coating processes, improper control can easily lead to the following problems:

Problem Types | Possible causes | Solutions |

| Paint film sagging | Too thick a coat, slow conveyor speed | Increase conveyor speed and apply layered spraying |

| Pinholes, pinholes | Water vapor or air bubbles mixed in | Increase atomization pressure and optimize flow rate |

| Incomplete drying | Coating too thick | Enhance drying energy or extend curing time |

| Surface ripples | Uneven paint mist distribution | Adjust spray overlap and spray distance |

Therefore, while pursuing a thick film effect, it is essential to consider leveling properties and curing conditions to avoid quality issues caused by excessive thickness.

What are the methods for adjusting the coating thickness of automatic painting machines?

Most modern reciprocating automatic spraying machines are equipped with intelligent control systems, allowing for coating thickness adjustment in the following ways:

• Setting the spray gun output flow rate (ml/min) on the touchscreen;

• Adjusting the spray gun movement speed (m/s);

• Setting the number of reciprocations or a two-way spraying mode;

• Controlling the conveyor belt speed;

• Automatically adjusting the spray gun distance based on the workpiece height.

These parameters can be set independently or stored as process recipes for automatic recall.

What is the maximum coating thickness of automatic painting machines?

Based on a comprehensive analysis of various process parameters and coating characteristics, the following conclusions can be drawn:

• The standard coating thickness for reciprocating automatic spraying machines is 20–60 μm;

• The maximum single-layer coating thickness is approximately 80–120 μm (depending on the paint type and spraying speed);

• If layered spraying with intermediate drying is used, the cumulative thickness can reach over 150 μm;

• The key to thickness control lies in the precise coordination of spray gun flow rate, spray distance, speed, and coverage;

• In thick-film spraying processes, priority should be given to ensuring sufficient drying and surface smoothness, avoiding sacrificing quality for the sake of thickness.

Therefore, when asked:

“What is the maximum coating thickness of a reciprocating automatic spraying machine?”

The most professional answer is:

“Under standard operating conditions, a single layer is approximately 60μm; with optimized processes, it can reach 120μm; and the cumulative thickness of multiple layers can exceed 150μm.”

What makes XMF Machinery stand out among coating machine brands?

XMF Machinery is not just another supplier; it is a manufacturer with deep expertise in coating and printing technology. Our company combines advanced R&D with precision factory production to deliver high-quality machines at competitive prices.

Customers appreciate our ability to provide reliable equipment, transparent quotes, and professional technical services. When buyers choose our brand, they gain both durable machinery and cost savings through wholesale promotions and discounts.