Industry sanding machines are essential equipment in modern manufacturing and processing industries. Their primary function is to sand, smooth, and polish the surfaces of various materials to meet production process and product quality requirements. Industry sanding machines are widely used in woodworking, metalworking, plastics, furniture manufacturing, and other surface treatment industries.

This article will provide a detailed explanation of the definition, types, operating principles, structural features, applications, and usage and maintenance of industry sanding machines.

What is an industry sanding machine?

An industry sanding machine is a device specifically designed for mechanically grinding material surfaces. Its core function is to smooth or remove surface irregularities by applying sandpaper, abrasive belts, or a grinding wheel to the workpiece surface, achieving the desired smoothness and precision. Unlike manual sanding, industry sanding machines deliver efficient, stable, and controllable results, significantly improving production efficiency and quality.

Primarily used in industrial production environments, industry sanding machines are designed for durability, continuous operation, and precision. Not only can it process large quantities of material, but it can also adjust parameters such as sandpaper grit, rotational speed, and feed rate to suit different materials and process requirements, thus meeting various industrial processing needs.

What are the types of industrial sanding machines?

Depending on the processing method and process requirements, industrial sanding machines can be divided into several types, each with different operating principles and application scopes. Common types include:

1. Belt Sanding Machine

Belt sanding machines are one of the most common types of industrial sanding machines, commonly used for sanding wood, sheet metal, and plastic surfaces. They utilize a continuously rotating abrasive belt to rub against the workpiece surface at high speed, achieving uniform grinding. Belt sanding machines are suitable for processing large surfaces and can efficiently remove rough surfaces or old paint.

2. Disc Sanding Machine

Disc sanding machines use circular sanding discs for grinding, which typically rotate at high speed. Disc sanding machines are suitable for edge grinding and small-area fine processing. They are commonly used for polishing the edges of wood products such as furniture, doors, and windows. They achieve a precise, smooth finish and are particularly well-suited for grinding curved and irregularly shaped workpieces.

3. Drum Sanding Machine

Drum sanding machines use a drum as the grinding medium, grinding through contact between the rotating drum and the workpiece. Drum sanding machines are suitable for processing thick panels or when large amounts of material need to be removed quickly. They offer high processing efficiency and can achieve surface smoothing for large batches of workpieces in a short period of time.

4. Calender Sanding Machine

Calender sanding machines consist of two counter-rotating abrasive rollers, with the workpiece being ground by friction between the rollers. This type of industrial sanding machine is ideal for achieving uniform surface grinding on panels, and is particularly effective when processing wood or composite materials. Calender sanding machines maintain consistent surface thickness and ensure processing accuracy.

5. Other Special Types

In addition to the common types mentioned above, industrial sanding machines also include multi-functional combination sanding machines, vibrating sanding machines, and industrial sanding equipment for automated production lines. These machines are often customized for specific industries and processes to meet the processing needs of specialized workpieces.

How does an industrial sanding machine work?

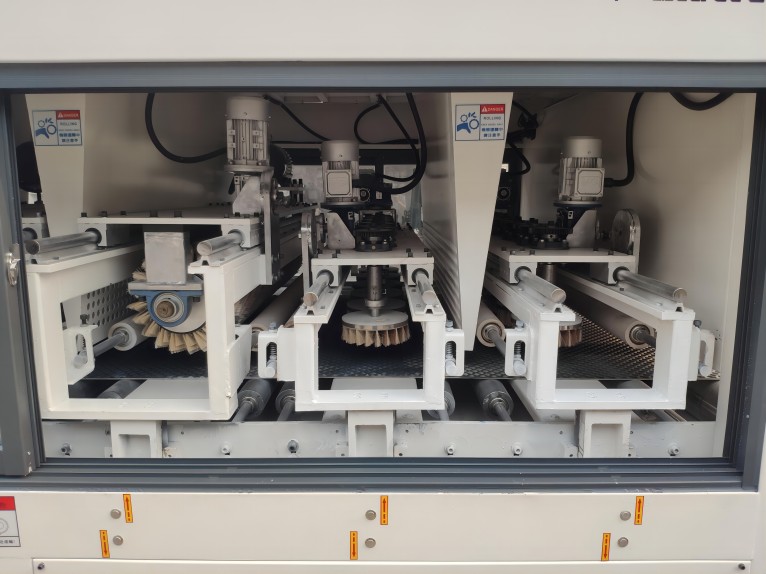

An industrial sanding machine primarily uses friction to remove surface irregularities, achieving a flat or smooth surface. Its core components include a power unit, abrasive media (sandpaper, abrasive belts, grinding wheels, etc.), a transmission mechanism, and a workpiece support and guide system.

• Power Unit: Typically driven by an electric motor, it drives the abrasive belt, abrasive disc, or grinding wheel at high speed through a transmission mechanism, providing the mechanical power for grinding. Some high-end equipment uses variable-frequency motors, which can adjust the speed according to different materials, achieving precise processing.

• Grinding Media: Sandpaper, abrasive belts, grinding wheels, or drums coated with wear-resistant particles are the core components of an industrial sanding machine. The grinding medium contacts the workpiece surface, using friction to remove surface material, achieving a smooth or polished finish.

• Drive mechanism: The device that transmits power from the motor to the abrasive belt, disc, or drum, including gears, belts, bearings, etc. The drive mechanism ensures the stability and uniformity of the grinding motion, thereby ensuring machining accuracy.

• Workpiece support system: This system secures or guides the workpiece, maintaining the appropriate contact pressure and angle with the abrasive medium to ensure consistent machining. Workpiece support systems typically offer adjustable height, angle, and feed speed to accommodate workpieces of varying sizes and shapes.

Through the coordinated operation of these four core systems, industrial sanding machines achieve efficient and uniform surface finishes in a short time. Depending on the sandpaper grit size and grinding time, coarse, medium, or fine grinding can be achieved to meet various surface finish requirements.

What are the applications of industrial sanding machines?

Industry sanding machines are widely used in various surface treatment and processing industries. Specific application areas include:

• Woodworking: Industry sanding machines are widely used in wood processing, including surface smoothing and polishing for furniture manufacturing, wooden doors, wood floors, and wood decorative materials. Sanding machines can remove burrs and old paint layers from wood surfaces, achieving a smooth and even finish.

• Metalworking: Industry sanding machines are used to polish the surfaces of metal sheets, pipes, and components to remove burrs, oxide layers, and weld marks. Metalworking sanding machines typically use wear-resistant grinding wheels or belts to ensure machining accuracy and surface quality.

• Plastics and Composites: Plastic products and composite sheets are prone to surface unevenness or scratches during production. Industry sanding machines can achieve a smooth surface, ensuring quality for subsequent painting or assembly.

• Furniture Manufacturing and Decorative Materials: Industry sanding machines are used for fine grinding and polishing of furniture surfaces, enhancing the product's texture and feel and ensuring the adhesion of paint or coatings.

• Surface Treatment and Finishing: During surface finishing, an industry sanding machine can remove minor imperfections and improve the surface finish of workpieces, providing a high-quality foundation for subsequent coating, electroplating, or painting.

Industry sanding machines are suitable for a variety of industrial production scenarios requiring high-efficiency, high-precision surface processing and are essential equipment for ensuring product quality.

Industry Sanding Machine: Usage and Precautions

Proper use of an industry sanding machine not only improves production efficiency but also extends equipment life and ensures operational safety. Key usage instructions and precautions include:

• Selecting the appropriate sandpaper or belt: Choose sandpaper or belts of varying grit sizes based on material hardness and processing requirements to achieve either coarse or fine grinding.

• Adjusting sanding machine parameters: Adjust the belt speed, feed rate, and pressure to ensure uniform grinding without damaging the workpiece.

• Secure the workpiece: The workpiece should be securely fixed or kept in a stable position to prevent it from shifting during sanding, which could affect the finish.

• Keep the equipment clean: Regularly clean dust and grinding debris from the sanding machine surface to prevent clogging of the drive system and reduced grinding performance.

• Check the grinding media: Regularly check the wear of the sanding belt or grinding wheel and replace them promptly to ensure processing quality and safe operation.

• Safe operation: Operators should wear protective glasses, masks, and gloves to avoid injury from splashing from the high-speed sanding belt or grinding wheel. Before operation, ensure that the emergency stop device is functioning properly.

Through proper use and maintenance, industrial sanding machines can operate stably and for a long time, ensuring production efficiency and product quality.

Industry Sanding Machine: Maintenance and Care

Industry sanding machines are high-intensity equipment. Proper maintenance and care are key to extending equipment life and maintaining processing accuracy. Key maintenance methods include:

• Regularly lubricate the drive system: Keep bearings, gears, and sliding components lubricated to reduce wear and vibration.

• Check the sanding belt and grinding wheel for wear: Promptly replace severely worn sanding belts or grinding wheels to ensure processing quality and equipment safety.

• Clean Dust and Grinding Debris: Use compressed air or a vacuum cleaner to clean dust from the sanding machine's surface and interior to prevent clogging and damage to the motor.

• Calibrate Equipment Accuracy: Regularly check the belt tension, sanding disc balance, and guide system to ensure uniform grinding and machining accuracy.

• Electrical System Maintenance: Check the motor, electronic control system, and wiring to prevent leakage or short circuits and ensure stable equipment operation.

Through scientific maintenance measures, industrial sanding machines can maintain high performance over the long term, meeting the needs of continuous industrial production.

Can buyers purchase wholesale from XMF Machinery?

Absolutely. XMF Machinery provides wholesale supply of coating equipment, helping customers lower purchasing costs and benefit from discounts. Our company’s sales model allows both small businesses and large factories to buy directly from our manufacturer facilities.

Wholesale purchasing ensures affordable prices while maintaining the same high quality guaranteed by our brand. Whether you require roller coaters, spray machines, or UV curing units, we are the supplier offering flexible purchasing and wholesale prices.