In modern furniture manufacturing, metal spraying, woodworking, and other industrial fields, CNC automatic painting machines have been widely used in various precision spraying operations. With their advantages of efficiency, precision, and high degree of automation, CNC automatic painting machines are gradually replacing traditional manual painting operations and becoming an indispensable piece of equipment in modern spray painting lines.

However, despite the powerful functions and highly intelligent control systems of CNC automatic painting machines, improper operation and inadequate maintenance can still lead to serious consequences such as reduced paint quality, equipment damage, and even safety hazards.

Therefore, the correct use of CNC automatic painting machines and understanding of the "taboos" during operation are crucial knowledge for every operator, equipment manager, and factory manager.

This article will delve into various aspects: what operational behaviors and management oversights should be avoided when using CNC automatic painting machines to ensure paint quality, extend equipment life, and reduce operational risks.

What are the taboos when using a CNC automatic painting machine?

Precautions when using a CNC automatic painting machine:

First: Operational Taboos

1. Do not skip the pre-startup self-test.

2. Do not manually intervene in the running spray gun or slide system

3. Do not start the machine without setting the spray parameters

Second: Spray Material Taboos

1. Do not use unfiltered paint

2. Do not mix different types of paint or solvents

Third: Maintenance Taboos

1. Do not neglect routine cleaning of the nozzle and paint pump

2. Do not leave the nozzle unsealed during extended downtime

Fourth: Safety Operation Taboos

1. Do not operate in poorly ventilated environments

2. Do not modify CNC programs by non-professionals

Fifth: Management System Taboos

1. Do not operate the machine without maintenance records

2. Do not operate the machine without operator training

First: Operational Taboos

1. Do not skip the pre-startup self-test

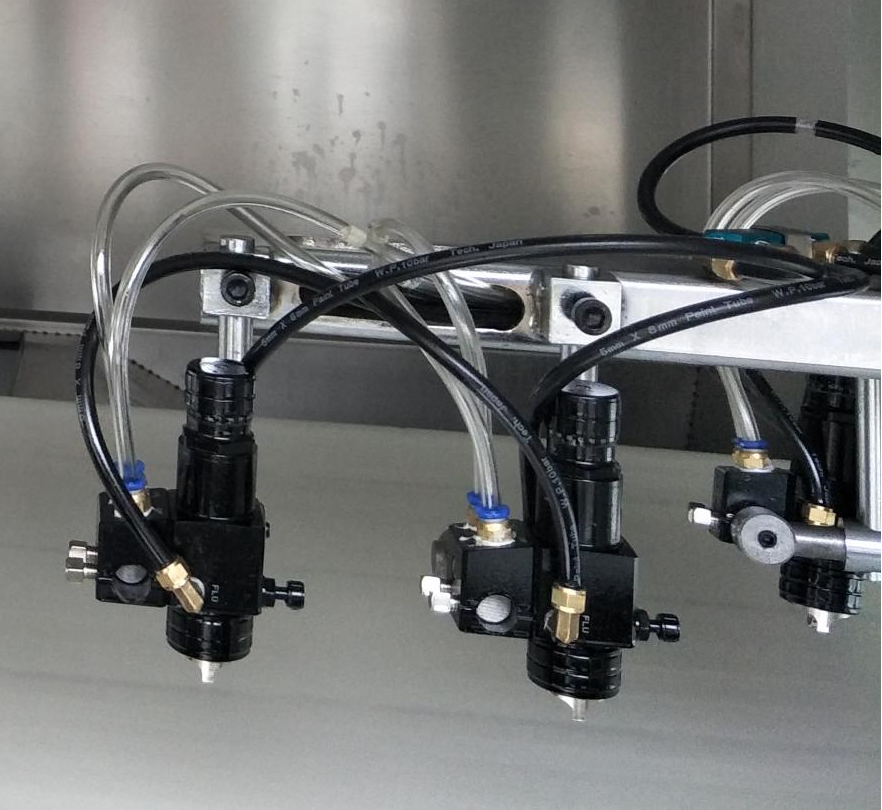

Before starting a CNC automatic painting machine, initialization steps such as power supply test, servo system self-test, air pressure monitoring, and spray gun solenoid valve inspection are typically required. Skipping these steps could result in the spray gun malfunctioning at best, or even worse, problems such as positional deviation and distorted spray paths during operation.

Must-Do:

· Complete the power-up self-test strictly according to operating procedures;

· Verify that the air compression system and filtration system are in normal condition;

· Check that the nozzle is unobstructed and that the servo motor has no fault alarms;

· Ensure that all fasteners are secure and not loose.

2. Do not manually intervene in the operating spray gun or slide system

During the spraying process, the CNC control system precisely controls the spray gun's trajectory, position coordinates, and spray speed through programming. Operators are strictly prohibited from interfering with moving parts with their hands or tools. Doing so will seriously disrupt program control and may even cause the spray gun to crash, break, or cause the motor to overload and burn out.

Must-Do:

· Press the emergency stop button first when encountering an abnormal situation;

· Wait until the system has completely stopped before performing any manual intervention;

· Operators should stay away from the moving axis.

3. Do not start painting without setting spray parameters

Although CNC automatic painting machines can memorize multiple spray programs, key parameters, including spray gun air pressure, flow rate, on/off delay, spray width, spray speed, and spacing, must be reset before each spraying batch.

Spraying without adjusting these parameters can lead to uneven paint coverage, bubbling on the painted surface, and noticeable color variations.

Do the following:

· Set appropriate parameters based on the material, shape, and area of the workpiece;

· Test a small sample before changing paint or product;

· Do not copy and paste a previous program without adjusting it.

Second: Taboos on Spray Material Use

1. Do not use unfiltered paint

Unfiltered paint often contains impurities or solid particles. These foreign matter can easily clog the CNC automatic painting machine's nozzle system, seriously affecting the spraying effect and potentially damaging the equipment.

The following must be followed:

· All paints must be filtered through a 100-300 mesh filter before use;

· Never repeatedly stir settled paint and then inject it directly into the system;

· Regularly clean the paint lines and pump.

2. Do not mix different types of paint or solvents

Paint types (such as polyurethane, nitrocellulose, and water-based) have different chemical properties. Mixing them can not only cause chemical reactions and precipitation, but can also corrode and damage the inner walls and seals of the CNC spray system.

The following must be followed:

· Only use the specified paint type in the same system;

· When changing paints, thoroughly clean the entire paint circuit system;

· Do not mix different types of solvents in the system.

Third: Maintenance taboos

1. Do not neglect routine cleaning of the nozzle and paint pump

If the nozzle, hose, and pump are not cleaned promptly after spraying, residual paint will gradually harden and form a film, leading to pipe blockage and flow abnormalities, seriously affecting the next spraying session.

The following must be done:

· Immediately clean the system with a dedicated cleaning agent after spraying daily;

· Use high-pressure air to blow away any residual liquid in the spray gun;

· Perform a deep maintenance on the oil pump and paint supply system weekly.

2. Do not leave the nozzle unsealed during extended downtime

Exposing the spray gun to air for extended periods can easily cause residual paint to dry on the nozzle surface, forming a film. This can severely distort the spray pattern or even completely block the spray pattern during the next use.

The following must be done:

· Clean and seal the nozzle with lubricant if the machine is down for more than two hours;

· Close the main air supply valve and paint supply system during downtime to ensure an airtight seal.

Fourth: Safety Operation Taboos

1. Do not operate in poorly ventilated environments

CNC automatic painting machines release volatile substances such as atomized particles and solvent vapors during operation. Poor ventilation can pose safety risks such as poisoning or explosion.

The following must be done:

· Install an industrial exhaust system and filter;

· Ensure good air circulation in the spray shop and that solvent concentrations do not exceed standards;

· Ensure that workers wear respirators and protective clothing.

2. Non-professionals are prohibited from modifying CNC programs

CNC programs control the entire spray gun path, trajectory, start and stop points, speed, and other parameters. Unauthorized program modification can easily cause imbalanced operation, spray offset, or mechanical damage.

Must-do:

·Program modifications must only be performed by trained programming technicians;

·Back up the original program before all program modifications;

·Perform a virtual path preview and test spray after each modification.

Fifth: Management System Taboos

1. Operation without maintenance records is prohibited

Many factories rely on field experience when operating CNC automatic painting machines and fail to establish systematic operation and maintenance records. This makes it difficult to identify equipment problems and reduces maintenance efficiency.

Must-do:

·Establish a daily maintenance, cleaning, and repair log for the equipment;

·Every abnormal malfunction must be recorded in detail as a basis for improvement;

·A dedicated person is responsible for tracking equipment operating status and maintenance.

2. Prohibit machine operation without prior training

CNC automatic painting machines involve multiple disciplines, including programming, control, pneumatic systems, and fluid systems. Direct operation by untrained personnel will lead to risks in spraying quality and equipment failure.

Requirements:

· New employees must undergo both technical and safety training before starting work;

· Conduct monthly operational review training and case studies;

· Prohibit unauthorized access to core control systems.

Do you support small and medium-sized enterprise purchasing?

Yes, we do. XMF Machinery accommodates small and medium-sized clients as well as large manufacturers. As a flexible supplier and company, we offer cost-effective standard modular machines with low prices, promotions, or entry-level package quotes to suit smaller production lines.

Whether you need just a single roller coater or a small spray system, we provide transparent prices, optional discounts, and friendly sales service. We scale up with customized or full-line solutions when needed.