A UV flatbed printing machine is a device that uses UV-cured ink to directly print high-precision images onto the surface of rigid or flexible materials. Its advantages include wide applicability to various materials, high print quality, instant curing, and ready-to-use output. Disadvantages include higher equipment and consumable costs, strict requirements for managing white ink and thick ink layers, sensitivity to height and shading, and stringent maintenance and safety management requirements.

Below, I will answer questions such as "Why is this the case?", "Where are the specific advantages?", "What physical/chemical mechanisms cause the disadvantages?", and "How should they be controlled and accepted in production?", providing you with a systematic, professional, and immediately applicable explanation for decision-making and operation.

What is a UV flatbed printing machine?

1. What exactly does a UV flatbed printing machine do?

A UV flatbed printing machine is a type of "flatbed digital inkjet printer" that directly sprays UV-curable ink onto a flat or near-flat workpiece (wood, acrylic, metal, glass, ceramics, leather, PVC, plywood, etc.) using a printhead. Then, a UV light source (mercury lamp or LED) instantly irradiates the ink, causing photopolymerization and cross-linking for rapid curing, resulting in high-resolution, saturated, and scratch-resistant images and layers.

Compared to roll-to-roll or transfer printing processes, UV flatbed printing machines can directly print on rigid, irregular, or pre-processed objects, which are ready to use immediately after printing without the need for prolonged drying.

2. Is UV "drying" ink? Why is it "instant curing"?

UV curing is not simply "solvent evaporation drying." Instead, the photoinitiator added to the ink generates free radicals/cations under UV light, driving the cross-linking of acrylic acid or other polymerizable monomers, instantly transforming the liquid state into a highly cross-linked solid film. Therefore, it can achieve "film formation in seconds, ready to use immediately after printing." This is the most fundamental technological advantage of UV flatbed printing machines.

What are the core components of a UV flatbed printing machine?

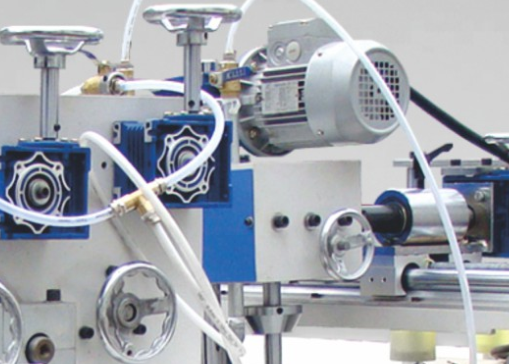

1. What are the key components of a typical UV flatbed printing machine?

• Printhead and drive system: Piezoelectric printhead array (high resolution), working in conjunction with a servo/stepping motion system to achieve precise dot-matrix positioning;

• Platform/clamp: Adsorption or vacuum table to ensure workpiece flatness and accurate positioning;

• Ink supply system: UV ink tank, circulation, filtration, and temperature control (printhead viscosity management);

• UV curing unit: LED or mercury vapor lamp module, multi-stage adjustable power and zone control;

• Control system: RIP color management, resolution/grayscale processing, layered/texture printing settings;

• Safety and environmental protection unit: Light shield/interlock, ozone emission/treatment (mercury lamp), waste ink collection, and ventilation system.

What are the advantages of a UV flatbed printing machine?

1. Wide Material Compatibility (Prints on virtually any rigid/soft surface)

UV inks cure on a variety of substrates to form a durable coating, making UV flatbed printing machines widely used for direct printing on materials such as wood, acrylic, metal, glass, ceramics, plastics, and leather, reducing pretreatment and transfer steps. This characteristic is a key reason why flatbed printers can replace many traditional processes.

2. High Print Quality, Vivid Colors, and Excellent Resolution

Digital piezoelectric printheads can output grayscale levels up to 600–1200 dpi or higher. Combined with the high color gamut and overprinting capabilities of UV inks, image detail, gradations, and contrast are excellent, making them suitable for signage, decorative panels, and product customization.

3. Instant Curing, Reduced Capacity and Processes

UV curing provides a "ready-to-use" production cycle advantage, reducing long drying times, manual handling, and stacking time, making it suitable for time-sensitive customized and industrial production.

4. Customizable Surface Functions (Embossing/Debossing/Tactile)

UV inks can be overprinted, and the thickness of each layer can be controlled by software to achieve a distinct embossed effect (3D effect) or combined with varnish overprinting for a tactile effect. This functional performance is unmatched by traditional offset printing. Suitable for value-added decoration such as door panels, signs, and handicrafts.

5. Environmental Advantages (Relative)

Compared to traditional printing with large amounts of solvents, UV-cured inks, especially 100% solid or low-VOC formulations, do not rely on large amounts of solvent evaporation during the curing process, thus reducing volatile organic compound emissions. However, emissions vary greatly between different ink systems, and actual workshop pollution control measures should be considered.

What are the disadvantages of a UV flatbed printing machine?

1. High Equipment and Consumable Costs

The purchase cost of a UV flatbed printing machine (including the entire machine, LED/mercury lamp modules, precision printheads, vacuum stages, etc.) and the cost of UV inks are significantly higher than those of ordinary solvent thermal transfer or screen printing. This is especially true for spot color inks such as white ink, which are used in large quantities and are expensive. This directly impacts the unit printing cost and must be amortized in capacity calculations.

2. High Requirements for White Ink and Thick Ink Layer Management

Printing white or opaque backgrounds often requires multiple undercoats and reflow to prevent nozzle clogging. Furthermore, the elasticity, adhesion, and opacity of cured white ink are complex, and improper management can lead to cracks, peeling, or printhead blockage. White ink issues are one of the common operational challenges in flatbed UV printing.

3. Printing Height and Shadow Limitations (Physical Limitations)

The height of the printhead from the material surface is strictly limited (commonly only a few millimeters to tens of millimeters), therefore it cannot be used for extremely tall or unevenly deep three-dimensional objects. Furthermore, UV curing relies on light exposure; insufficient curing in recessed/shaded areas necessitates multi-angle irradiation or curing by flipping the surface, increasing process complexity.

4. Strict Safety and Environmental Management Requirements for UV Light Sources (Mercury Lamps/LEDs)

Mercury vapor lamps may produce ozone and contain mercury waste. While LEDs have narrow energy distribution and low heat load, they require high precision in matching the ink spectrum. UV chambers require strict light-shielding and interlocking designs. During operation, UV leakage and ozone exceedances must be prevented, and discarded mercury lamps must be treated as hazardous waste.

5. Maintenance and Operating Costs (Frequent Printhead Maintenance and Cleaning)

High-precision printheads are sensitive to ink viscosity, impurities, and solvents. Long-term operation requires regular cleaning, maintenance, filtration, and circulation management. Printhead replacement and calibration are time-consuming and costly, impacting overall production line uptime.

6. Restrictions on Waste and Transportation Due to Special Ink Properties

UV inks and waste inks have unique chemical properties. Transportation, storage, and disposal must comply with relevant regulations and manufacturer SDS (Safety Statement Specifications), otherwise, compliance risks and additional costs will arise.

UV flatbed printing machine: What are the most common quality problems during operation?

Problem A: Color deviation, color gamut not meeting standards

• Causes: Improper RIP configuration, ink batch differences, printhead dust, insufficient curing energy leading to color deviation.

• Solutions: Establish an ICC color management process; perform regular printing curve calibration; ensure ink supply temperature control and filtration; monitor and adjust online irradiance.

Problem B: White ink nozzle clogging/delamination/cracks

• Causes: Large white ink pigment particles, gelation before curing, high curing stress, or poor adhesion of the underlying layer.

• Solutions: Use a circulating heating and stirring system, apply white ink in layers (thin layers multiple times), optimize the curing dosage to avoid "over-curing the surface and under-curing the inner layer".

Problem C: Localized insufficient curing (shadows, depressions)

• Causes: Obstructed direct UV light or insufficient energy.

• Solutions: Design supplementary lighting positions, implement part-flipping curing, or use a curing line with multiple lamp positions and adjustable power; if shadowing issues persist, assess the suitability of flatbed printing.

Problem D: Printhead instability, minor banding

• Causes: Printhead array misalignment, ink supply pulsation, or material feed vibration causing printing banding.

• Solutions: Calibrate the servo system, optimize vacuum stage adsorption, improve ink filtration level, and stabilize ink supply pressure.

What should I focus on when buying a UV flatbed printing machine?

• Printhead type and resolution: Determines the finest visible detail and grayscale performance; select a printhead that matches the target output dpi/grayscale requirements.

• Platform size and load capacity: Ensure it can cover the largest workpiece size and thickness, and allow sufficient clamping space.

• UV Light Source Type: LED (low heat, long lifespan, environmentally friendly) or mercury lamp (broad spectrum, strong penetration); selected based on ink and process.

• Ink Supply and White Ink Handling Solution: Includes white ink circulation, heating, stirring, and automatic cleaning modules.

• Control and Color Management: Built-in RIP, ICC support, grayscale control, and dot density management functions.

• Safety and Environmental Features: Light-shielding interlock, ozone treatment, waste ink recovery, and exhaust capacity.

• After-sales Service and Spare Parts: Availability of printheads, LED modules, and controllers, and manufacturer support policies.

How does XMF Machinery support global buyers?

Our company exports coating and printing equipment worldwide, offering convenient purchasing options for customers across different regions. We supply machines through direct factory sales, ensuring buyers get high-quality equipment at low prices without middlemen. Whether purchasing a single unit or wholesale lots, international customers benefit from competitive shipping quotes, fast delivery schedules, and the trusted reputation of a reliable Chinese manufacturer.