In modern manufacturing and woodworking, industrial wide belt sanding machines, as efficient and precise surface finishing equipment, play an irreplaceable role. With the continuous development of industrialized production, surface finishing accuracy and efficiency have become key concerns for all manufacturers, and industrial wide belt sanding machines are essential equipment for meeting this demand.

This article focuses on the core question, "What are industrial wide belt sanding machines used for?" and systematically examines their application scenarios, processing principles, applicable materials, and specific roles in the production process, aiming to provide a comprehensive and professional reference for industry practitioners and researchers.

What is an industrial wide belt sanding machine?

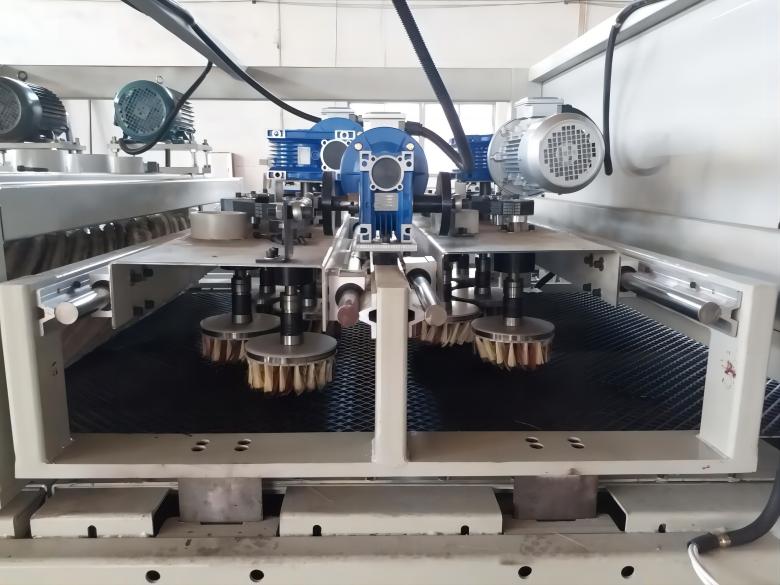

An industrial wide belt sanding machine is an automated mechanical device that uses abrasive belts or screens to smooth, deburr, polish, and fine-tune workpiece surfaces. Compared to traditional manual sanding, industrial wide belt sanding machines offer high processing efficiency, excellent process uniformity, convenient operation, and a high degree of automation. Its core structure typically includes an abrasive belt conveyor system, a pressure roller mechanism, a tensioning mechanism, a power system, and a control system, enabling continuous and stable grinding of workpiece surfaces.

The belt width of an industrial wide belt sanding machine is generally wider, allowing it to cover a larger workpiece area. It can also achieve varying degrees of roughness by adjusting the belt speed and pressure. Due to its high efficiency and precision, industrial wide belt sanding machines are widely used in various fields, including sheet metal processing, furniture manufacturing, door and window production, and metal surface treatment.

What is the processing principle of an industrial wide belt sanding machine?

To understand the application prospects of industrial wide belt sanding machines, it is necessary to first understand their basic processing principles. The core function of an industrial wide belt sanding machine is friction grinding of the workpiece surface by the abrasive belt. The high-speed rotation of the abrasive belt continuously contacts the workpiece surface, creating micro-cuts on the workpiece surface, removing surface irregularities, burrs, and oxide layers, resulting in a smooth, flat surface.

The grinding process on an industrial wide belt sanding machine is typically divided into the following steps:

1. Initial Rough Sanding

In this stage, the industrial wide belt sanding machine uses a coarse-grit abrasive belt to quickly remove excess material and burrs from the workpiece surface, ensuring the required overall flatness. This stage primarily targets workpieces with uneven surfaces or significant defects.

2. Fine Sanding

After the initial sanding, the industrial wide belt sanding machine switches to a medium- and fine-grit abrasive belt to fine-tune the workpiece surface. By adjusting the abrasive belt speed and pressure, the surface roughness can be precisely controlled, laying a solid foundation for subsequent coating or machining.

3. Polishing

After fine sanding, some industrial wide belt sanding machines are equipped with a polishing device or ultra-fine abrasive belts to further improve the workpiece surface finish, achieving a mirror or semi-mirror finish.

Using a multi-stage abrasive belt system and adjustable pressure control, industrial wide belt sanding machines provide a complete sanding process from roughing to finishing. This continuous processing capability is unmatched by manual sanding.

What are industrial wide belt sanding machines used for?

Regarding the core question of "What are industrial wide belt sanding machines used for?", the applications of industrial wide belt sanding machines can be explained in detail from three perspectives: material type, processing objectives, and industry needs.

1. Applications of Industrial Wide Belt Sanding Machines in Wood Processing

Wood processing is one of the primary applications of industrial wide belt sanding machines. Industrial wide belt sanding machines perform critical surface treatment tasks in furniture manufacturing, solid wood flooring, wooden doors and windows, and woodcraft production. Their specific functions include:

• Removing Burrs and Surface Irregularities

After sawing, planing, and carving, wood surfaces often have burrs and rough textures. Industrial wide belt sanding machines, using their wide sanding belts at high speeds, can quickly and evenly remove burrs, smoothing the wood surface and creating an ideal surface for subsequent painting or splicing.

• Adjusting Wood Thickness and Size

Industrial wide belt sanding machines can fine-tune wood thickness while maintaining a smooth surface. Precisely controlling the sanding belt pressure and feed speed ensures consistent thickness across each batch, improving product processing accuracy.

• Improving Coating Results

Wood surface roughness directly impacts coating quality. Sanding with an industrial wide belt sander results in a smooth, even wood surface, improved paint adhesion, and a smooth, bubble-free, and spot-free finish.

• Surface Patterning

During the production process, some high-end furniture or handicrafts require industrial wide belt sanding machines to enhance patterns or detail, giving the wood a more natural and aesthetically pleasing texture.

2. Applications of Industrial Wide Belt Sanding Machines in Metalworking

Although industrial wide belt sanding machines originated in the woodworking industry, they also have important applications in metal surface treatment. In the metalworking industry, industrial wide belt sanding machines are primarily used for:

• Removing Oxide Layers and Rust

Metals are prone to developing oxide layers or slight rust during storage or processing. Industrial wide belt sanding machines can effectively remove these surface deposits and restore the metal surface to a smooth finish.

• Surface Smoothing

For metal sheets or parts, industrial wide belt sanding machines can eliminate burrs and uneven areas generated during processing, ensuring a smooth surface and paving the way for subsequent welding, painting, or assembly.

• Surface Polishing

In the production of certain high-end metal products, a mirror-like finish is required. Industrial wide belt sanding machines achieve a high-gloss finish by using fine abrasive belts.

• Weld Mark Removal

In metal welding processes, welds often leave noticeable weld marks. Industrial wide belt sanding machines can be used to smooth welds, improving the overall aesthetics of metal workpieces while maintaining mechanical properties.

3. Application of Industrial Wide Belt Sanding Machines in Composite Material Processing

With the widespread use of composite materials and high-performance sheet metal, the role of industrial wide belt sanding machines in composite material processing is becoming increasingly prominent. Common uses include:

• Surface Smoothing

Composite materials are prone to uneven layers or surface roughness during production. Industrial wide belt sanding machines achieve uniform sanding, resulting in a smooth and consistent surface.

• Fine Burr Removal

Composite materials often have burrs on edges and joints after processing. Industrial wide belt sanding machines can efficiently remove these burrs, ensuring product dimensional accuracy and safety.

• Surface Texture Modification

For high-end composite materials, industrial wide belt sanding machines can achieve different texture effects by adjusting the sanding belt, improving the product's visual and tactile quality.

4. Auxiliary Roles of Industrial Wide Belt Sanding Machines in Other Industries

In addition to wood, metal, and composite material processing, industrial wide belt sanding machines are also used in industries such as plastics, furniture panels, flooring, and rubber products. Their main uses include:

• Surface Pretreatment

Before spraying or laminating, industrial wide belt sanding machines can evenly sand the material surface to enhance the adhesion of the coating or adhesive layer.

• Fine Polishing and Trimming

Industrial wide belt sanding machines can perform fine polishing and trimming on materials such as plastic sheets, rubber sheets, and composite sheets, improving product surface quality and dimensional accuracy.

• Cycle Optimization

Due to their high level of automation, industrial wide belt sanding machines enable continuous production, significantly improving production efficiency and shortening processing cycles.

Operating Characteristics of Industrial Wide Belt Sanding Machines

When considering the question "What are industrial wide belt sanders used for?", their operating characteristics are crucial to understanding their purpose. Industrial wide belt sanding machines typically have the following features:

• Wide Belt Processing: Industrial wide belt sanding machines feature a wide belt width, which can cover a large workpiece area and improve processing efficiency. They are particularly suitable for surface treatment of sheet metal and large workpieces.

• Automatic Tensioning and Speed Control System: Modern industrial wide belt sanding machines are equipped with an automatic tensioning device to ensure the belt maintains appropriate tension. The belt speed and workpiece feed speed can also be adjusted to meet different processing requirements.

• Multi-Level Abrasive Belt Combinations: The industrial wide belt sanding machine can be equipped with coarse, medium, fine, and polishing belts. This multi-level combination allows for complete processing from roughing to finishing, improving machining quality.

• Stable Pressure Wheel and Precise Pressure Control: The industrial wide belt sanding machine uses precise pressure control to ensure uniform contact between the abrasive belt and the workpiece surface, ensuring grinding uniformity and surface flatness.

What industries can benefit from XMF Machinery’s products?

XMF Machinery supplies surface coating and printing machines that are widely used in multiple industries. Furniture factories, flooring companies, door manufacturers, plastic and glass producers, as well as ceramics and metal processing brands, all rely on our equipment. By purchasing from our factory, buyers gain access to high-quality machines at low prices and benefit from customized solutions adapted to different industries.

Our company offers wholesale sales, promotions, and quotes for bulk purchasing, making it a cost-effective investment in our products.