In recent years, industrial wide belt sanding machines and industrial roller sanding machines, as two commonly used sanding equipment in the industry, have attracted widespread attention from producers and technicians. Many people ask a core question when choosing sanding equipment: Is an industrial wide belt sanding machine better than an industrial roller sanding machine?

This article will analyze in depth the differences between industrial wide belt sanding machines and industrial roller sanding machines from multiple perspectives such as equipment structure, processing accuracy, and applicability, in order to help enterprises and technical personnel rationally choose equipment that is suitable for their own production needs.

Industrial wide belt sanders vs. industrial roller sanders: What are they?

1. Industrial wide belt sanding machine

Industrial wide belt sanding machine, also known as high-speed wide belt sanding machine, is an automated sanding equipment that uses wide belt sand as the working medium. Its characteristic is that the sand belt has a large width, which can cover a wide surface of the board at once, achieving high-speed and continuous processing. Industrial wide belt sanding machines typically use multiple sets of grinding wheels, multi-stage pressure rollers, and advanced automatic tension adjustment systems to ensure the stability and flatness of the sand belt during processing. Its structural design usually includes feeding mechanism, sand belt drive device, pressure roller adjustment system, dust collection device, and control system.

2. Industrial roller sanding machine

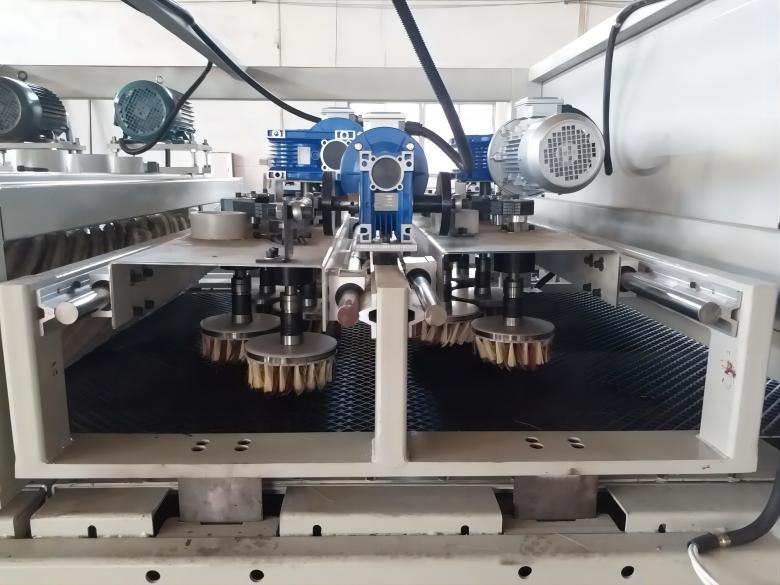

An industrial roller sanding machine is a device that uses sandpaper to cover a drum for sanding processing. The basic principle is to use a drum to rotate and drive sandpaper to rub against wood or board, thereby removing surface defects and leveling the surface. The structure of an industrial roller sanding machine is relatively simple, usually including a drum, sandpaper device, feeding mechanism, and dust collection system. Roller sanding machines generally have a small width and limited coverage in a single processing, making them suitable for narrow sheets or specific surface treatment requirements.

Industrial wide belt sanding machine vs. roller sanding machine: comparison of working modes

1. Working principle of industrial wide belt sanding machine

The industrial wide belt sanding machine uses high-speed rotating sand belts for friction processing. The board enters the sanding zone through the feeding mechanism, and the sand belt uniformly contacts the surface of the board under tension and pressure roller, achieving material grinding. Wide belt sanding machines often use a combination of multiple sand belts or multi station processing designs, which can complete coarse, medium, and fine sanding processes in one go, improving production efficiency. Wide belt sanding machines are usually equipped with floating pressure rollers or pneumatic adjustment devices during the processing, which can automatically adapt to small thickness changes on the surface of the sheet and ensure surface flatness.

2. Working principle of industrial roller sanding machine

Industrial roller sanding machines mainly rely on the rotation of rollers covered with sandpaper for friction sanding. After the board enters the drum area, surface grinding is achieved through the contact between the drum and sandpaper. The working mode of a roller sanding machine is relatively direct, and the sanding intensity depends on the drum speed, sandpaper thickness, and feeding speed. Due to the fact that roller sanding machines are typically used for single station processing, their machining accuracy and surface uniformity may be limited on wide width boards.

Industrial wide belt sanding machine vs. roller sanding machine: comparison of machining accuracy

1. Advantages of industrial wide belt sanding machine

The industrial wide belt sanding machine has significant advantages in surface machining accuracy. The design of wide sanding belt and floating pressure roller enables the sanding belt to automatically adjust the pressure on the contact plate, avoiding local indentation or uneven wear. Multi segment sand belt combination or multi station design can achieve the completion of coarse sand, medium sand, and fine sand in one go, reducing errors caused by multiple back and forth processing of the board. The surface of the board processed by the wide belt sanding machine has high smoothness and uniform thickness, making it particularly suitable for processing large boards and furniture panels.

2. Characteristics of industrial roller sanding machines

Industrial roller sanding machines are slightly inferior in machining accuracy compared to wide belt sanding machines. The sanding pressure of a roller sanding machine mainly depends on the weight of the drum itself and the spring pressure plate, and cannot be precisely adjusted for pressure distribution like a wide belt sanding machine. For large or wide boards, roller sanding machines may exhibit uneven edge sanding or central depression. Roller sanding machines are more suitable for processing small sheets or processes that require lower surface accuracy.

Industrial wide belt sanding machine vs. roller sanding machine: comparison of production efficiency

The industrial wide belt sanding machine has significantly higher production efficiency than the industrial roller sanding machine due to the use of wide sanding belts and multi station design. The wide belt sanding machine can process wider boards at once and achieve multi-stage sanding processing, reducing the handling time of boards on the production line. High speed operation and automated control systems make industrial wide belt sanding machines more advantageous in large-scale production.

Relatively speaking, the width of industrial roller sanding machines is limited, and the coverage of a single processing is small, usually requiring multiple feeding to complete the sanding of wide boards. The production efficiency is limited by the width of the drum, feeding speed, and operating mode, so in high-yield, continuous production environments, the efficiency of roller sanding machines is lower than that of wide belt sanding machines.

Industrial wide belt sanding machine vs. roller sanding machine: comparison of applicable scope

1. Applicability of industrial wide belt sanding machine

The industrial wide belt sanding machine is suitable for various board processing, such as particle board, density board, multi-layer board, and solid wood board surface processing. Its wide width design and automatic pressure adjustment function enable it to handle large furniture panels, door panels, and decorative panels. The wide belt sanding machine is particularly suitable for processing scenarios that require high surface smoothness and thickness uniformity, such as high-end furniture production, wood flooring processing, and precision board surface treatment.

2. Applicability of industrial roller sanding machines

Industrial roller sanding machines are suitable for narrow width sheets or special surface treatment processes, such as local polishing, edge finishing, and small batch processing. Its structure is simple and easy to operate, suitable for surface treatment of mid to low end furniture or boards with low processing requirements. When processing large wide sheets or high-precision surfaces, roller sanding machines have certain limitations.

Industrial wide belt sanding machine vs. roller sanding machine: analysis of operating costs

1. Cost characteristics of industrial wide belt sanding machines

Industrial wide belt sanding machines are usually mid to high end sanding equipment with high investment costs. The equipment has a complex structure and is equipped with automatic tension adjustment, multi-stage pressure rollers, and high-precision control system, which increases its purchase and maintenance costs relatively. However, the advantages of wide belt sanding machines in production efficiency and processing accuracy can reduce labor costs and increase output in long-term production, thereby achieving economic returns.

2. Cost characteristics of industrial roller sanding machines

The industrial roller sanding machine has a simple structure, low production and manufacturing costs, and relatively low purchase and maintenance expenses. For small and medium-sized enterprises or production environments with low processing requirements, roller sanding machines can effectively control equipment investment. However, due to relatively limited production efficiency and processing accuracy, long-term large-scale production may increase labor costs and rework costs, which may be slightly inferior in terms of economic benefits.

Industrial wide belt sanding machine vs. roller sanding machine: maintenance and operation comparison

Due to its complex structure, industrial wide belt sanding machines require professional operators for debugging and maintenance. Sand belt replacement, roller adjustment, and control system maintenance must be strictly carried out in accordance with operating specifications. The wide belt sanding machine requires high operational accuracy during use, but its automation level is high, reducing the impact of human error.

The industrial roller sanding machine has a simple structure and is relatively easy to operate and maintain. Sandpaper replacement and roller maintenance are convenient, suitable for ordinary operators to use. However, a simple structure also means that the control of machining quality mainly relies on operational experience, with limited automation and precise control capabilities.

Is an industrial wide belt sanding machine better than a roller sanding machine?

From a comprehensive performance perspective, industrial wide belt sanding machines are significantly superior to industrial roller sanding machines in the following aspects:

1. Processing accuracy: The wide belt sanding machine has a high surface finish and uniform thickness, suitable for high-precision production.

2. Production efficiency: Broadband design and multi station sanding greatly improve production efficiency.

3. Scope of application: It can handle large boards and high-end furniture panels, with wide adaptability.

4. Automation level: Pressure regulation, tension control, and multi-stage sanding functions achieve automated production, reducing human operational errors.

However, industrial wide belt sanding machines have high investment costs and maintenance requirements, and operators need to have a certain level of technical proficiency. Industrial roller sanding machines have low investment and easy operation and maintenance, making them suitable for small-scale or low demand production scenarios.

Therefore, whether it is "better" depends on the production needs and budget of the enterprise. If pursuing high efficiency, high precision, and wide width sheet metal processing, industrial wide belt sanding machines are undoubtedly a better choice; If only small-scale, low-cost, and easy-to-use sanding equipment is needed, industrial roller sanding machines still have their market value.

Does XMF Machinery provide customized coating equipment?

Yes, XMF Machinery is a professional company with strong R&D capabilities, and we specialize in delivering customized coating and printing solutions. Whether you need a roller coater for doors, a UV curing machine for flooring, or a specialized spray system for ceramics, our factory can design and manufacture according to your requirements.

Customers can buy equipment tailored to different substrates, coatings, and production processes. We provide high quality machines at competitive prices, with wholesale purchasing options and discounts available for large orders.