In the furniture manufacturing industry, the quality of the surface coating of the boards directly determines the appearance, feel, and durability of the product. Among numerous coating equipment, the Curtain Coating Machine, with its efficient and uniform coating effect, has become an indispensable piece of equipment in furniture board production.

Many manufacturers ask when purchasing coating equipment: Is a Curtain Coating Machine suitable for furniture boards?

The answer is—absolutely.

This article will systematically explain why the Curtain Coating Machine is such a perfect fit for the surface treatment needs of furniture boards.

What is a Curtain Coating Machine?

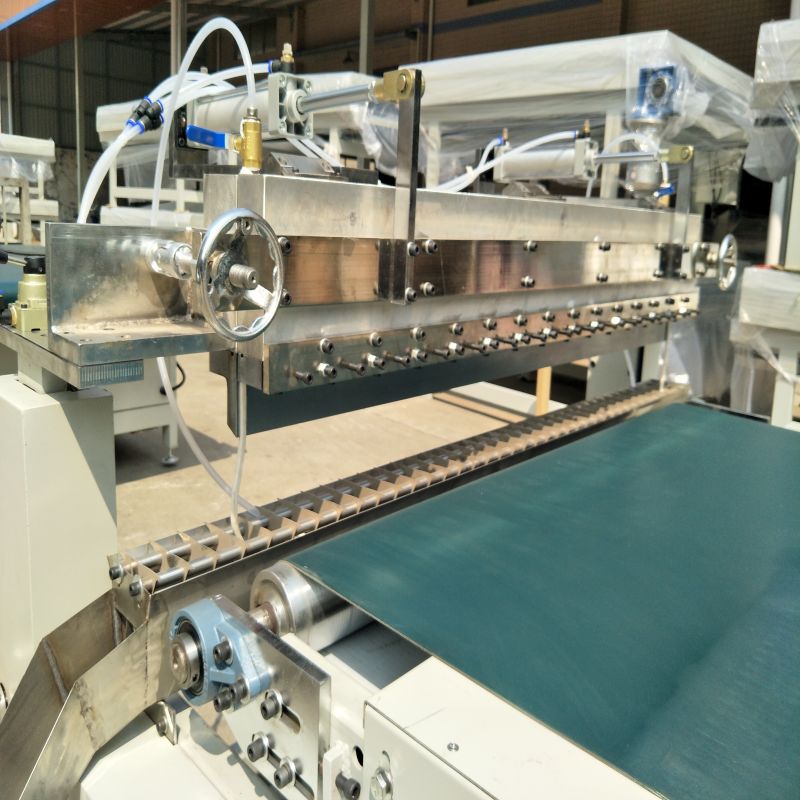

A Curtain Coating Machine is a mechanical device that uses the principle of free fall for coating. Simply put, it uses a special paint reservoir to create a continuous and uniform "coating curtain." As the furniture board passes under this curtain, the coating is evenly applied to the board surface.

The main components of a Curtain Coating Machine include:

• Paint circulation system: Ensures continuous paint flow and maintains a stable viscosity.

• Curtain Forming System: Controls the coating to form a stable curtain under gravity.

• Conveying System: Stably conveys furniture panels through the coating area.

• Recycling System: Recycles excess coating, reducing waste.

The essence of the Curtain Coating Machine lies in the formation of the "fluid curtain." It requires a balance of coating fluidity, surface tension, and viscosity to form a uniform, dense, and bubble-free coating on the furniture panel. This characteristic is what gives the Curtain Coating Machine its superior consistency and high-quality surface finish in furniture panel coating.

Why is the Curtain Coating Machine particularly suitable for furniture panel surface coating?

Furniture panel surfaces typically require a smooth, even surface, consistent color, and good adhesion and abrasion resistance. The Curtain Coating Machine's coating method perfectly meets these requirements. Specifically:

1. Stable and Controllable Coating Thickness

Curtain Coating Machines can precisely control coating thickness by adjusting flow rate, drop height, and conveyor speed. They can achieve precise application of different coatings, such as primer, topcoat, and sealant, on furniture panels.

2. High Surface Smoothness

The coating falls naturally from above, virtually unaffected by air turbulence or mechanical pressure, resulting in a naturally leveled coating with extremely high gloss.

3. High Coating Efficiency

Compared to roller coating machines or spray coating, the Curtain Coating Machine enables continuous production, suitable for high-volume furniture board processing, increasing production efficiency several times over.

4. Coating Savings and Better Environmental Friendliness

Because excess coating can be recycled, the Curtain Coating Machine significantly reduces coating waste. Furthermore, the coating process is virtually spray-free, making it more environmentally friendly.

What Types of Materials Can the Curtain Coating Machine Handle?

The Curtain Coating Machine has a very wide range of applications, covering almost all types of boards commonly used in furniture manufacturing. These include:

• MDF (Medium-Density Fiberboard): Its dense surface and strong adsorption properties make it ideal for curtain coating.

• Particleboard and engineered wood: The Curtain Coating Machine effectively fills in minor depressions, creating a smooth surface.

• Plywood and melamine board: It can be used as a sealing primer layer, providing a base for subsequent lamination or painting.

• UV furniture boards and high-gloss boards: The Curtain Coating Machine evenly applies UV coatings, enhancing gloss and hardness.

It's worth noting that the Curtain Coating Machine is not only suitable for wood-based panels but also for surface coating of plastic boards, metal boards, and stone-coated boards. As long as the coating formulation and fluid parameters are properly adjusted, the same excellent coating quality can be maintained.

What are the advantages of the Curtain Coating Machine compared to other coating methods?

Many furniture factories compare Curtain Coating Machines, roller coaters, and spray coaters when choosing coating equipment. In fact, Curtain Coating Machines offer significant advantages in the following aspects:

1. Higher Coating Uniformity

Roller coating machines are prone to uneven thickness on complex textures or large panels; spray coating machines are affected by spray angle and airflow. Curtain Coating Machines, however, utilize a "liquid curtain" to ensure uniform coverage of every inch of furniture board.

2. Suitable for High-Gloss and Mirror-like Effects

The coating formed by Curtain Coating Machines is dense, smooth, and easily leveled, making it particularly suitable for furniture board surfaces requiring high gloss and a mirror-like finish.

3. High Production Efficiency and Simple Maintenance

Curtain Coating Machines have a compact structure, are easy to clean and adjust; compared to spray coating, they require less maintenance of spray guns and less frequent nozzle replacements.

4. No Overspray Waste

Due to gravity coating, no air pressure is required, eliminating paint atomization loss and achieving a paint utilization rate of over 98%.

How does Curtain Coating Machine ensure coating adhesion and durability on furniture boards?

Furniture board coatings not only need to be aesthetically pleasing but also withstand the challenges of friction, cleaning, and temperature and humidity changes during use. Curtain Coating Machines offer natural advantages in coating adhesion and durability:

1. Excellent Coating Wetting

During curtain coating, the coating directly covers the board in a liquid curtain form, allowing for full penetration into micropores and improving adhesion.

2. Fewer Bubbles and Pinholes

Compared to spray coating, Curtain Coating Machines produce virtually no bubbles or pinholes, reducing subsequent repair steps.

3. Perfect Integration with UV Curing Lines

In UV furniture board production, Curtain Coating Machines are often used in conjunction with UV dryers, enabling integrated coating and curing production, resulting in coatings with high hardness and strong abrasion resistance.

4. High Coating Density

Due to gravity, the coating naturally levels, resulting in a dense molecular arrangement, thus enhancing chemical resistance and scratch resistance.

What are the key operational points to note when using a Curtain Coating Machine for furniture boards?

Although Curtain Coating Machines are highly automated, the following key points must be mastered during furniture panel coating to achieve optimal performance:

1. Coating Viscosity Control

The viscosity of the coating determines the stability of the liquid curtain. Excessive viscosity can lead to curtain breakage, while insufficient viscosity results in a thin coating or sagging.

2. Drop Height and Flow Rate Adjustment

The drop height of the coating curtain is generally between 20–40 cm, depending on the coating characteristics and the size of the furniture panel. The optimal balance should be found through experimentation.

3. Conveyor Speed Matching

Excessive conveyor speed can lead to uneven coating, while insufficient speed increases the risk of sagging. A speed of 5–15 meters per minute is generally recommended.

4. Environmental and Temperature Stability

Curtain Coating Machines are sensitive to temperature and humidity. Maintaining a stable workshop temperature is crucial to prevent fluctuations in the rheological properties of the coating.

5. Regular Cleaning and Maintenance

The coating tank and return piping should be cleaned regularly to prevent coating deposition or solidification and maintain liquid curtain stability.

Is a Curtain Coating Machine suitable for mass production in furniture factories?

The answer is yes. Curtain Coating Machines are inherently designed for mass production of furniture panels. They can be integrated with equipment such as feeders, UV dryers, and sanders to form automated production lines, enabling continuous operation from primer to topcoat to sealer.

This production method not only significantly improves efficiency but also ensures coating consistency and standardized appearance for each furniture panel, reducing manual intervention and increasing overall production yield.

Is a Curtain Coating Machine compatible with different types of coatings?

Yes, Curtain Coating Machines have extremely high coating adaptability. Commonly used coatings include:

• PU (Polyurethane) coatings

• UV-cured coatings

• Acrylic resin coatings

• Water-based wood coatings

• PE (Polyester) coatings

After adjusting viscosity, surface tension, and flow rate, these coatings can achieve ideal coating results in a Curtain Coating Machine, meeting the diverse needs of furniture panels.

What are the economic benefits of a Curtain Coating Machine?

From a long-term perspective, Curtain Coating Machines not only improve production efficiency but also significantly reduce overall costs:

1. High Coating Utilization

Almost all uncoated coating can be recycled, minimizing waste.

2. Low Labor Costs

High degree of automation, requiring only a small number of operators for monitoring.

3. Low Maintenance Costs

Simple mechanical structure, eliminating the need for frequent parts replacements, ensuring stable long-term operation.

4. Consistent Quality and Reduced Rework Rate

High coating consistency significantly reduces rework losses caused by surface defects.

Are XMF Machinery’s UV curing machines suitable for industrial applications?

Yes, XMF Machinery’s UV curing machines are designed for high efficiency and energy-saving operation, suitable for furniture, flooring, plastic, and metal surfaces. Buyers can purchase directly from our factory at low prices, benefiting from wholesale promotions and discounts. Our company provides customized machines to match different production lines and coatings.

With professional technical support, clear quotes, and competitive pricing, XMF Machinery ensures that customers worldwide receive reliable and high quality equipment for fast and precise curing processes.