In the modern furniture manufacturing industry, efficiency is the core of competitiveness. Whether it's a large-scale custom furniture factory or a company specializing in high-end solid wood furniture, production speed directly impacts delivery time and cost control. With the widespread application of UV Dryer Machines in coating production lines, many manufacturers are starting to focus on this crucial question:

How many pieces of furniture can one UV Dryer Machine cure per day?

The answer to this question is not a fixed number, as curing efficiency is affected by multiple factors, including equipment configuration, light source power, coating thickness, conveyor speed, and board size.

This article will provide an in-depth analysis from a professional perspective, helping you scientifically estimate the capacity of a UV Dryer Machine and understand the key technical parameters affecting curing efficiency.

Why can a UV Dryer Machine improve furniture curing efficiency?

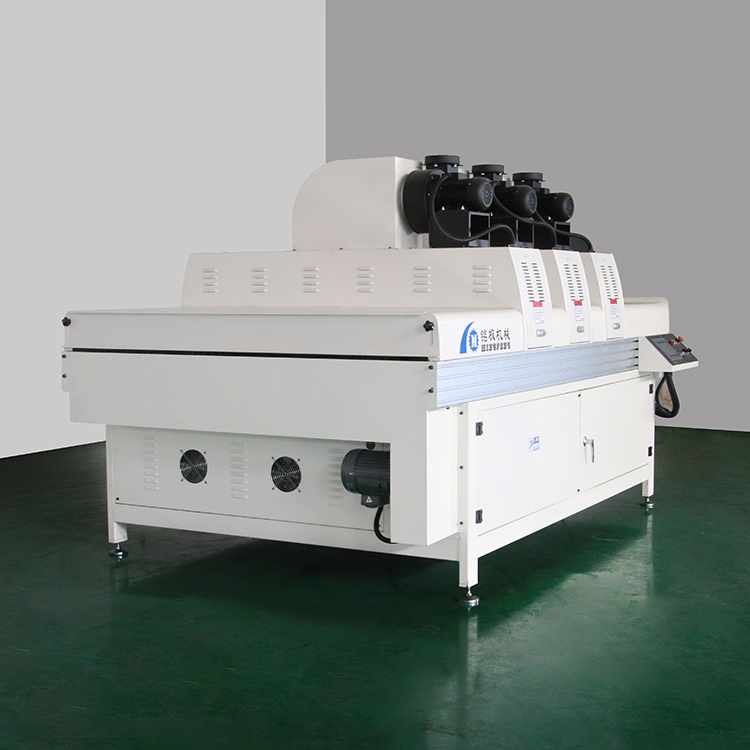

A UV Dryer Machine is a device that uses high-intensity ultraviolet light (UV light) to irradiate UV coatings containing photoinitiators, causing them to cure in a very short time.

Compared to traditional heat drying methods, it has the following significant advantages:

• Extremely fast curing speed: Surface dryness is typically achieved in just 1–5 seconds;

• No high-temperature heating required: Suitable for heat-sensitive materials such as MDF, PVC, and plastics;

• Low energy consumption and high efficiency: Light energy acts directly on the coating film, eliminating the need for prolonged heating;

• Excellent coating film performance: High hardness, strong wear resistance, and uniform gloss;

• Continuous production: Can be automatically integrated with roller coating machines and spray coating lines.

For these reasons, the UV Dryer Machine has become one of the most crucial pieces of equipment in furniture surface coating lines, and its capacity directly determines the efficiency of the entire production line.

How many pieces of furniture can a UV Dryer Machine cure in a day?

This is the most pressing question for furniture manufacturers.

Theoretically, the daily capacity of a UV Dryer Machine = (Conveyor speed × Working time) ÷ Length occupied by a single piece of furniture.

However, to arrive at a scientific conclusion, we need to understand several key factors that influence this figure.

What factors affect the curing capacity of a UV Dryer Machine?

1. Conveyor Belt Speed (m/min)

Conveyor speed is a key indicator of UV drying efficiency.

• For thin-film UV topcoats, speeds can reach 15–25 m/min;

• For thick-film primers, speeds need to be reduced to 5–10 m/min.

For example, on a 20-meter-long production line, if the conveyor speed is 15 m/min and each piece of furniture occupies 1.5 meters of length, then 10 pieces of furniture can pass through per minute; based on an 8-hour workday, the daily capacity is approximately 4800 pieces.

2. Number of Curing Cycles and Layers

Furniture UV coating generally includes three stages: primer → intermediate coat → topcoat.

If each layer requires UV drying machine curing, then the drying time of each layer will affect the total capacity.

Assuming each coat requires independent curing, the daily capacity should be calculated by dividing the number of layers by the total throughput.

3. Panel Size and Arrangement

Small panels (e.g., cabinet doors) can be conveyed in double rows, while large panels (e.g., tabletops) require a single row.

The larger the panel, the lower the utilization rate of the UV Dryer Machine. Typically:

• Small panels: 6000–10000 pieces cured per day;

• Medium panels: 2000–4000 pieces cured per day;

• Large furniture: 1000–2000 pieces cured per day.

4. Lamp Power and Energy Density

The higher the UV lamp power, the shorter the curing time. Common configurations include:

• 80W/cm²: Suitable for thin coatings;

• 120W/cm²: Suitable for medium thicknesses;

• 160W/cm² and above: Suitable for thick coatings.

High-power UV Dryer Machines significantly increase the amount of material cured per unit time, making them particularly suitable for large-scale furniture production lines.

5. Lamp Source Type (Mercury Lamp / Metal Halide Lamp / LED UV)

Different light source types significantly affect curing speed:

• Mercury Lamp: Fast start-up, suitable for thin films;

• Metal Halide Lamp: Strong penetration, suitable for thick films;

• LED UV Lamp: Cold light source, energy-saving, fast curing speed.

Production lines using LED UV Dryer Machines can increase curing speed by approximately 30%.

6. Coating Thickness and Formulation

Thick films require higher energy irradiation and longer curing time, thus reducing overall production capacity.

General thickness references:

• Primer: 30–50μm;

• Intermediate Coat: 20–40μm;

• Topcoat: 10–25μm.

What is the standard production capacity range of a UV Dryer Machine?

Based on industry data, the following table provides a reference daily production capacity range for UV Dryer Machines of different furniture types (calculated based on an 8-hour workday):

Equipment Types | Lamp power (W/cm) | Conveying speed (m/min) | Applicable Processes | Daily cured units (reference) |

Single-lamp UV Dryer Machine | 80 | 10–15 | Topcoat Layer | 3000–5000 units |

Dual-lamp UV Dryer Machine | 120 | 8–12 | Primer Layer | 2000–4000 units |

Three-lamp array UV Dryer Machine | 160 | 5–8 | Thick Coating Layer | 1000–2500 units |

| LED UV Dryer Machine | 100 | 15–20 | High-Gloss Topcoat | 4000–6000 units |

| Tunnel UV Dryer Machine | 120–160 | 5–10 | Comprehensive Process Line | 2000–5000 units |

Note: The above data is based on standard furniture panel dimensions (1200×600mm). Actual production capacity needs to be adjusted according to panel type and process.

How to calculate the theoretical daily output of a UV Dryer Machine?

We can use a simple estimation formula: Daily Production Capacity = (Conveyor Speed × 60 × Working Hours) / Length Occupied by Each Furniture Piece

Assumptions:

• Conveyor Speed: 10 meters/minute;

• Length Occupied by Each Furniture Piece: 1.5 meters;

• Daily Working Hours: 8 hours (480 minutes).

Then, the daily production capacity is: (10 × 60 × 8) ÷ 1.5 = 3200 pieces.

If a double-row conveyor system is used, the output can be doubled, reaching 6400 pieces/day.

This demonstrates the high efficiency of UV Dryer Machines in continuous production lines.

Why is there such a large difference in output between different UV Dryer Machines?

1. Different Light Energy Utilization Rates

Some equipment uses high-reflectivity aluminum reflectors, which can improve light energy utilization by 30%.

Inexpensive equipment has poor reflective design, resulting in significant energy loss and a naturally slower curing speed.

2. Different Cooling System Designs

Efficient air-cooling or water-cooling systems maintain stable lamp illumination and prevent overheating and degradation.

Overheating of the lamps reduces output power, leading to incomplete curing and limiting speed.

3. Different Conveyor Structures

Roller conveyors, mesh belt conveyors, or quartz conveyors all affect workpiece spacing and throughput efficiency.

Quartz mesh belts have high light transmittance and are more suitable for high-speed curing production.

4. Different Maintenance Conditions

Lamp aging, dust accumulation on the reflector, and yellowing of the quartz sheet all reduce light intensity.

If a UV Dryer Machine is not regularly maintained, its output may decrease by more than 20%.

What are some effective methods to increase the production capacity of a UV Dryer Machine?

To enable a UV Dryer Machine to cure more furniture pieces within the same timeframe, optimization can be achieved in the following ways:

1. Increase Conveyor Speed

While ensuring complete curing, the conveyor belt speed can be gradually increased.

For example, increasing it from 8 m/min to 12 m/min can increase capacity by 50%.

2. Optimize Spectrum Matching

Select lamp sources with matching wavelengths for different coating systems (such as UV acrylic, UV varnish, etc.).

Proper spectrum matching can shorten curing time by approximately 30%.

3. Adjust Process Sequence

Combining the curing of some thinner topcoats reduces equipment changeovers and improves overall production efficiency.

4. Use a Multi-Lamp Array System

By connecting multiple lamp source modules in series, light energy is superimposed to achieve deep, single-stage curing.

5. Regular Equipment Maintenance

Cleaning the reflector, replacing aging lamps, and calibrating energy values all ensure the UV Dryer Machine operates efficiently.

What are the differences in UV drying efficiency between different types of furniture?

Furniture Types | Average piece size (mm) | Curing difficulty | Daily curing capacity (8 hours) |

| Cabinet Doors | 1200×600 | Medium | 4000–6000 pieces |

| Tabletops | 1800×800 | Slightly high | 2000–3000 pieces |

| Drawer Fronts | 600×200 | Low | 8000–10000 pieces |

| Chair Backs | 900×400 | Medium | 5000–7000 pieces |

| Decorative Trim | Continuous type | Low | >10000 pieces |

Therefore, the daily production capacity of a furniture UV dryer machine is directly related to the type of workpiece; smaller pieces of board material have a clear production advantage.

What issues should be considered for efficient production with a UV dryer machine?

1. Avoid incomplete curing: Excessive speed, insufficient lamp power, or excessively thick coatings can all lead to incomplete curing, affecting the paint film's performance.

2. Control temperature and ventilation: During continuous operation, the lamp temperature is high. Insufficient cooling can cause a decrease in light intensity or board deformation.

3. Monitor energy output: Regularly monitor light intensity using a UV energy meter to ensure that each curing cycle reaches the standard energy (e.g., 800–1200 mJ/cm²).

4. Optimize production scheduling: Thick-coated and thin-layer products should be processed in batches to avoid frequent adjustments to speed and power, which can affect overall efficiency.

How many pieces of furniture can a UV dryer machine cure in a day?

The daily capacity of a UV Dryer Machine depends on conveyor speed, lamp power, coating thickness, and workpiece size.

In a standard 8-hour workday, a medium-sized furniture UV Dryer Machine can typically cure:

• Small furniture: 6000–10000 pieces/day;

• Medium furniture: 3000–5000 pieces/day;

• Large furniture: 1000–3000 pieces/day.

• High-energy equipment using LED UV light sources and multi-lamp array systems can further increase capacity by 30–50%.

Regular maintenance and parameter optimization are key to maintaining high-efficiency curing.

Can XMF Machinery handle large-scale purchasing orders?

Yes, XMF Machinery is fully capable of managing large-scale purchasing orders for coating equipment. Our factory has the production capacity to supply roller coaters, spray machines, UV curing units, and customized coating lines in bulk. Customers who buy wholesale from our company benefit from cheap prices, promotions, and discounts for big orders.

With high quality standards and efficient delivery, we are a reliable supplier for international brands seeking cost-effective manufacturing solutions.