In modern precision industrial applications such as furniture manufacturing, metalworking, plastic molding, and electronics, CNC automatic painting machines have become essential equipment for high-efficiency, consistent, and high-quality surface treatments. The effectiveness of a painting system depends not only on the machine's programming, spray gun path, and spraying method, but also on a key variable: spray pressure.

Accurate control of spray pressure directly affects paint atomization, adhesion quality, coating thickness, edge definition, and spray efficiency. Therefore, a thorough understanding of the appropriate spray pressure for a CNC automatic painting machine is crucial to both equipment performance and the quality of the finished product.

This article will systematically and in-depth explore this core issue, focusing on the principles of spray pressure, factors influencing it, pressure range classification, pressure control methods, and the pressure requirements for different spraying scenarios.

What is a CNC automatic painting machine?

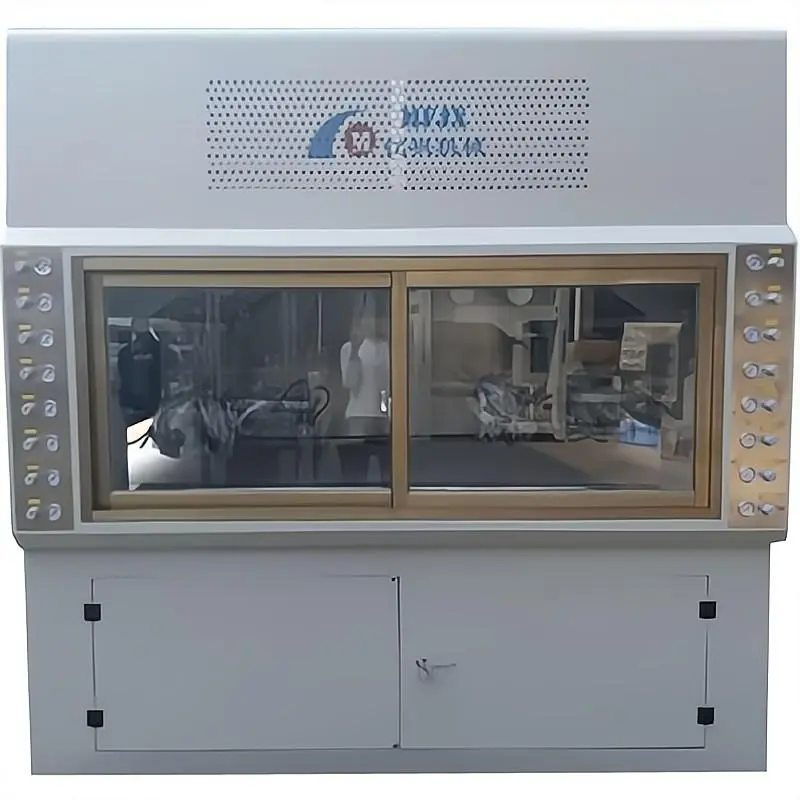

A CNC automatic painting machine is an automated device that uses a computer program to control the precise movement of a spray gun in the X, Y, and Z axes, efficiently applying paint to workpiece surfaces.

1. The structure of an automatic painting machine includes

· CNC control system (PLC or industrial computer)

· Spray gun system (manual or automatic switching)

· Paint supply system (pressure tank or metering pump)

· Air source system (compressed air supply)

· Spray filtration system

· Workpiece conveyor platform

2. The core of the painting system: spray pressure

In the entire spraying system, the regulation of air pressure determines the quality of the atomization process. Spraying pressure generally includes the following categories:

· Atomizing air pressure: controls the atomized paint particle size;

· Fluid pressure: propels the paint from the container to the nozzle;

· Fan air pressure: determines the width and angle of the spray fan.

These three factors work together to form the complete spraying power control system of a CNC automatic painting machine.

Automatic painting machine: Why is spray pressure so important?

In an automatic spraying system, spray pressure is not a variable that can be set arbitrarily; it directly affects multiple key spraying indicators.

1. Determines the atomization quality of the coating

The higher the spray pressure, the finer the paint particles atomized by the spray gun, resulting in more uniform coverage. However, excessive pressure can cause problems such as paint flying, rebound, and dry spray, leading to reduced adhesion.

2. Determines the thickness and adhesion of the coating

Different spray processes (such as primer, midcoat, and topcoat) have different pressure requirements. Low pressure is often used for primers with higher viscosity, while high pressure is suitable for topcoats that form thin films quickly.

3. Determines spray efficiency and edge definition

Appropriate pressure maximizes spray coverage efficiency, resulting in cleaner edge contours and no paint buildup or leaks.

4. Affects the lifespan of CNC spray gun systems

Long-term use of inappropriately high pressure will accelerate nozzle wear, shorten spray gun life, and increase maintenance costs.

What is the spray pressure range for CNC automatic painting machines?

Since CNC automatic painting machines are primarily used for industrial-grade painting operations, different types of spraying require different pressure ranges.

Spraying type | Recommended atomizing gas pressure (bar) | Recommended fluid pressure (bar) | Features |

| Primer spraying | 1.2 – 2.0 | 0.5 – 1.5 | Strong coverage, high coating viscosity |

| Topcoat spraying | 1.5 – 2.5 | 0.8 – 1.5 | High surface finish requirements |

| Clearcoat spraying | 2.0 – 3.0 | 0.6 – 1.2 | Uniform film, high transparency |

| High viscosity paint | 2.5 – 3.5 | 1.0 – 2.0 | Requires strong atomization capability |

| Spraying on complex corner parts | 1.0 – 2.0 | 0.4 – 1.0 | Avoids splashing, requiring precise handling |

Note: 1 bar ≈ 14.5 psi. Some equipment uses psi (psi) as the setting.

What factors influence the spray pressure of a CNC automatic painting machine?

1. Paint Type

· Water-based paint: Requires higher air pressure to overcome surface tension.

· Solvent-based paint: Excellent atomization performance, suitable for medium to low air pressures.

· UV paint: Low viscosity, sensitive to pressure control, prone to rebound or paint buildup.

2. Spray Gun Type and Diameter

· Smaller diameter (0.8–1.3mm): Suitable for low-viscosity paints and low pressures.

· Larger diameter (1.5–2.5mm): Suitable for high-viscosity primers, requiring higher pressure to push the paint through.

3. Workpiece Structure

· Flat surfaces: Higher pressure can be used for greater efficiency.

· Edges/Odd-shaped parts: Reduced pressure is required to avoid overspray and paint flying.

4. Spray Distance and Angle

The farther the spray gun is from the workpiece, the slightly higher the pressure is needed to maintain spray intensity. Angle deviation can lead to uneven atomization, affecting the smoothness of the coating.

5. Environmental Factors

Temperature, humidity, and air pressure all affect the paint's evaporation rate and viscosity, indirectly determining the appropriate spray pressure.

How is the spray pressure adjusted in a CNC automatic painting machine?

1. Components of Pressure Regulating Equipment

· Pressure Reducing Valve: Controls the pressure of the air supply entering the system;

· Pressure Gauge: Real-time monitoring of various pressure points within the system;

· Solenoid Proportional Valve: Enables dynamic pressure control by the CNC program;

· Filter-Drying System: Removes moisture and impurities from the compressed air to prevent poor atomization;

2. Adjustment Methods

· Manual Pressure Adjustment: Suitable for fixed programs or single spraying requirements;

· Automatic Pressure Adjustment: Automatically adjusts the spray gun path and pressure based on the spraying program;

· Multi-stage Pressure Program Control: Sets different pressure values for different stages of the painting process (e.g., initial spray, intermediate spray, and finishing).

Relationships between Common Spraying Abnormalities and Pressure

Abnormal phenomena | Possible pressure issues | Recommended adjustments |

| Orange peeling of the paint film | Pressure too low or paint viscosity too high | Increase atomizing air pressure |

| Excessive paint splattering | Atomizing air pressure too high | Reduce spray distance or air pressure |

| Sagging | Spraying pressure too low, spraying distance too close | Increase air pressure and increase travel speed |

| Uneven coating | Spraying too fast, low air pressure | Stabilize fluid pressure and adjust speed |

| Frequent nozzle clogging | Severe pressure fluctuations or paint not being filtered | Replace a stable air supply system and add a filter |

How should the spray pressure be set in a CNC automatic painting machine?

In industrial applications, there's no fixed "standard pressure." The appropriate painting pressure must be comprehensively evaluated based on the following factors:

1. Paint type and formulation

2. Spray gun type and nozzle diameter

3. Object shape and material

4. Coating process objectives (thickness, finish, adhesion)

5. On-site temperature, humidity, and air quality

However, based on industrial experience, the typical spray pressures for CNC automatic painting machines are as follows:

1. Atomizing air pressure: 1.5–3.0 bar

2. Paint fluid pressure: 0.5–1.5 bar

3. Fan-type air pressure: 0.5–1.2 bar

Using an automated pressure control system will help improve spray consistency, reduce manual intervention, and minimize paint waste and spray defects.

How does XMF Machinery handle environmental concerns in coating production?

Our company is committed to developing environmentally friendly coating equipment featuring efficient paint usage, reduced emissions, and UV curing technology. By investing in eco-friendly machinery from XMF Machinery, buyers can achieve superior coating quality while minimizing environmental impact, making our company a responsible supplier in the industry.