As a highly efficient and precise coating equipment, CNC automatic painting machines are gradually replacing traditional manual and semi-automatic spraying methods. When purchasing and using CNC automatic painting machines, in addition to focusing on their stability, efficiency, and finished product quality, the question of "how much paint is lost during the spraying process?" is frequently raised.

This article will provide a detailed, professional, and systematic analysis of the topic of "paint loss during the spraying process of CNC automatic painting machines."

What is the working principle of a CNC automatic painting machine?

The core feature of a CNC automatic painting machine lies in its precise control of the spray gun's trajectory, speed, spraying pressure, and atomization method through numerical control programming, achieving accurate coating coverage.

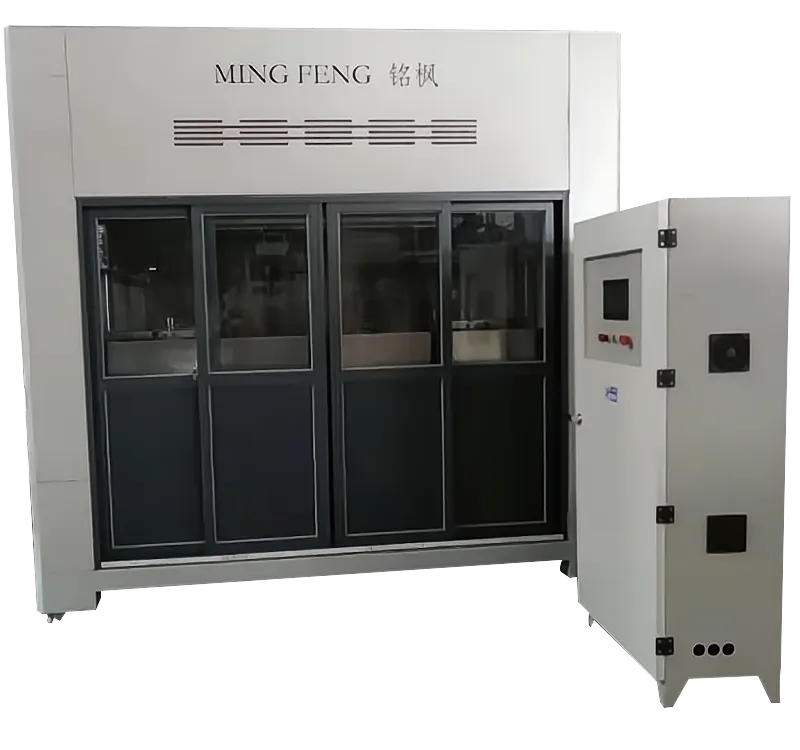

A typical CNC automatic painting machine consists of the following key systems:

• CNC drive system: controls the movement path and speed of the spray gun;

• Spraying material supply system: continuously delivers paint to the nozzle;

• Spray gun system: achieves atomized spraying of the paint;

• Pneumatic system: controls the atomizing air pressure and forming airflow;

• Exhaust and paint mist recovery system: collects excess paint particles;

• Intelligent control interface: sets the spraying process parameters.

These systems work together to ensure uniform and precise spraying, but they also involve "loss points" in the spraying process, which will be analyzed one by one below.

Main Sources of Paint Loss in Spraying

Although the control precision of a CNC automatic painting machine is much higher than that of manual spraying, some paint loss is still unavoidable. The main types of loss include the following:

1. Air Atomization Loss (Overspray)

This is the most common form of loss in spraying. 1. Overspray: When paint is atomized and sprayed from a spray gun, some paint mist does not land on the workpiece surface but diffuses into the air or outside the sprayed area, forming overspray zones.

• High-pressure atomization can result in losses as high as 20%-30%;

• Low-pressure high-flow (HVLP) or medium-pressure spray guns can reduce losses to 10%-15%;

• Optimizing the distance between the spray gun and the workpiece (usually 15-25cm) helps control losses.

2. Internal Equipment Residue

Components such as pipes, spray guns, paint pumps, and filters in the painting system require cleaning after each operation. Residual paint that has not been sprayed becomes a waste.

• The amount of residue per application depends on the length of the paint path and the diameter of the paint pipe;

• Using short-distance feeding systems and metered spraying devices can reduce this type of loss.

3. Insufficient Conversion

Efficiency of the Recycling System: Some CNC automatic painting machines are equipped with recycling systems (such as paint mist recovery devices or electrostatic recovery), which can theoretically recover unattached paint particles. However, due to equipment efficiency limitations, not all recovered materials can be reused.

• Ordinary dry filters have a recovery rate of 40%-60%;

• Using wet spray booths and electrostatic spraying in combination can increase paint utilization to 80%-90%.

4. Spray Path Planning Errors

If the spray path design is unreasonable, problems such as repeated spraying and edge dry spraying will significantly increase paint consumption.

• CNC program optimization and graphic scanning systems can reduce this loss;

• Precise path control can make the amount of paint used per unit area approach the theoretical value.

Automatic Painting Machine: Key Factors Affecting Paint Loss

1. Spray Gun Type and Nozzle Specifications

The spraying efficiency of different spray guns directly determines the paint mist adhesion rate.

• Commonly used HVLP spray guns produce fine atomization and are highly efficient;

• Traditional high-pressure spray guns produce large atomization dispersion and severe overspray;

• Nozzle diameters (e.g., 1.3mm, 1.5mm, 1.8mm) should be matched to different paint types; nozzles that are too large or too small will affect adhesion efficiency.

2. Spray Pressure Setting

Improper paint and gas pressure settings can also lead to paint waste.

• Excessive forming air pressure causes splattering;

• Insufficient atomization pressure results in inadequate atomization and reduced adhesion efficiency;

• The optimal spray air pressure range is typically 1.8~2.5 bar.

3. Spray Gun Movement Speed and Path Density

Too fast a spray gun movement can cause insufficient adhesion, while too slow a movement results in repeated spraying. The spray overlap ratio should generally be controlled between 40% and 60%, and the distance between the spray gun and the surface should be constant.

4. Workpiece Surface Complexity

• Flat surfaces have the highest coating efficiency;

• Irregularly shaped parts, corners, and curved surfaces are more difficult to paint, leading to increased blind spots and repainting areas, and decreased paint utilization;

• CNC automatic painting machines can solve this problem to some extent through intelligent path scanning systems.

What is the paint loss rate of a CNC automatic painting machine?

Based on actual equipment parameters and typical operating conditions, the average paint loss rate of a CNC automatic painting machine can be estimated as follows:

Spraying Methods | Theoretical utilization rate | Actual loss rate range | Features |

High-Pressure Traditional Spray Gun | 40%-60% | 40%-60% | High paint loss, coarse atomization, severe overspray |

| HVLP Low-Pressure Spray Gun | 65%-80% | 20%-35% | High adhesion rate, suitable for flat surface painting |

| Electrostatic Spraying System | 80%-90% | 10%-20% | Effectively reduces paint mist diffusion, but the equipment is complex |

| CNC Reciprocating Sprayer | 75%-85% | 15%-25% | Precisely controls the spraying area, reducing repainting |

| CNC + Automatic Recovery System | 85%-90% | 10%-15% | Equipped with a recycling system, significantly improving paint utilization efficiency |

In summary, if a standard CNC automatic painting machine is used with an HVLP spray gun, and the spraying process parameters are set reasonably, an average loss rate between 15% and 25% is within the normal range. If combined with a paint recovery system or electrostatic spraying system, the loss can potentially be reduced to around 10%.

Automatic Painting Machine: How to Reduce Paint Loss? —Recommendations

To utilize paint resources more efficiently, users can optimize the use of the CNC automatic painting machine in the following ways:

1. Precisely Set the Spraying Program

• Use CAD model scanning to match the path;

• Set reasonable spray width overlap and spraying angle;

• Avoid repeated spraying at corners and dry spraying.

2. Reasonably Select Spray Guns and Nozzles

• Select appropriate spray gun models for paints of different viscosities;

• Clean nozzles regularly to avoid spray direction deviation.

3. Improve Work Environment Control

• Control airflow and temperature/humidity in the spray painting workshop to avoid airflow interference;

• Install an exhaust system to prevent paint mist rebound and contamination of the spraying area.

4. Install a Paint Recovery System

• Collect oversprayed paint using dry filters or a wet spray booth;

• Maximize paint reuse to reduce actual consumption.

5. Use High-Quality Paints and Thinners

• High-concentration, high-efficiency film-forming paints have high adhesion rates;

• Thinner selection affects atomization quality and drying speed.

CNC Automatic Painting Machine: Paint Loss Is Unavoidable

A certain amount of paint loss is unavoidable during the spraying process of a CNC automatic painting machine, but the loss is far lower than that of traditional spraying methods. Under standard operating conditions, using modern CNC equipment, high-efficiency spray guns, and a spray path control system, the paint loss rate can be controlled between 15% and 25%. By introducing auxiliary methods such as electrostatic spraying and a recovery system, the loss rate can even be reduced to below 10%.

To maximize the paint utilization efficiency of a CNC automatic painting machine, the key lies in mastering scientific spraying parameter settings, appropriate equipment selection, and routine maintenance.

Is XMF Machinery a factory or a trading company?

XMF Machinery is a professional factory and manufacturer, not just a trading company. This allows us to control production quality, supply directly to buyers, and offer competitive low prices without extra costs. Customers benefit from wholesale purchasing, factory promotions, and direct communication with our engineers. By buying directly from the manufacturer, clients receive high-quality coating equipment, customized solutions, and affordable quotes. As a trusted supplier, our company combines the advantages of a factory with the service of a global brand, ensuring long-term cooperation with buyers worldwide.