Tiles are a widely used decorative material in modern construction, and their surface treatment technology is a crucial aspect of the construction process. The "industrial wide belt sander" is widely used in flooring, wood, and metal surface treatment, but many industry professionals and construction workers have raised the question: Can an industrial wide belt sander sand tiles?

This article will provide a detailed analysis from multiple perspectives, including the equipment's principles, material properties, construction techniques, and operational precautions, to answer this professional question.

What is an industrial wide belt sander?

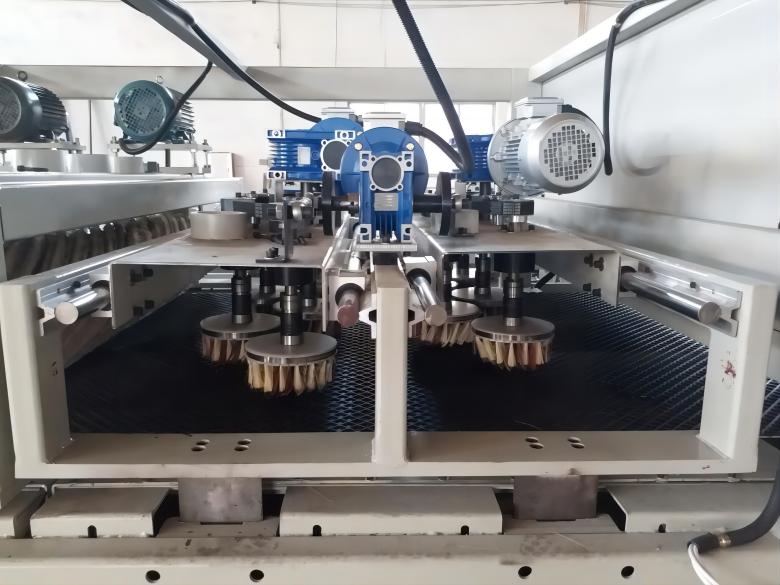

An industrial wide belt sander is an industrial device used for grinding large-area material surfaces. Compared to traditional handheld sanders, industrial wide belt sanders have the following main characteristics:

1. Wide sanding belt

Industrial wide belt sanders use wide sanding belts, typically ranging from 500mm to 1500mm in width. The wide design allows for the coverage of a larger area at once, improving surface treatment efficiency.

2. High-Power Drive System

To handle large-area continuous operation, industrial wide belt sanders are typically equipped with motor systems ranging from 2kW to 15kW, enabling high-speed and stable operation.

3. Uniform Pressure Distribution Mechanism

Industrial wide belt sanders use air pressure or spring systems to adjust the contact pressure between the sanding belt and the workpiece surface, ensuring uniform grinding results and reducing surface scratches.

4. Adjustable Speed and Sanding Belt Tension

The equipment usually allows adjustment of the sanding belt speed and tension to adapt to the grinding needs of different materials. For different surfaces such as metals, wood, and composite materials, optimal grinding results can be achieved through parameter adjustments.

5. Waste Collection and Dust Removal System

Industrial wide belt sanders are equipped with efficient dust removal or suction systems that collect dust during the sanding process, ensuring a clean working environment and reducing damage to equipment and operators.

In principle, industrial wide belt sanders rely on the high-speed friction of the sanding belt against the material surface to uniformly remove the surface layer, achieving smoothing, polishing, or deburring. This principle is well-established in wood processing and metal sheet surface polishing.

However, the problem lies in the fact that ceramic tiles are a hard and brittle material, with a surface hardness and brittleness fundamentally different from wood and metal. Therefore, whether an industrial wide belt sander is suitable for polishing requires analysis from the perspectives of material properties, belt type, and processing methods.

What are the characteristics of ceramic tile material?

Ceramic tiles are mainly divided into glazed tiles, polished tiles, unglazed tiles, and microcrystalline stone, etc. Their common characteristics are high hardness and high brittleness, with surface friction strength significantly different from wood or metal. Specific characteristics are as follows:

• High Hardness: The Mohs hardness of ceramic tiles is typically between 6 and 8, especially polished tiles and microcrystalline stone, which have higher hardness, limiting the frictional ability of ordinary abrasive belts. High hardness means rapid belt wear during polishing and a tendency to result in uneven surface.

• High Brittleness: Ceramic tiles are prone to cracking and chipping. When an industrial wide belt sander operates continuously at high speed, improper belt pressure or speed can easily lead to surface cracks or edge damage.

• Differences in surface finish: Glazed tiles have higher surface hardness but a thinner glaze layer; unglazed tiles have uniform hardness but a high coefficient of friction; microcrystalline stone has a smooth and hard surface, making it difficult for traditional abrasive belts to effectively grind. This means that the adaptability of industrial wide belt sanders varies across different tile materials.

• Thermal sensitivity: High-speed friction easily generates localized high temperatures, and since tiles have a low coefficient of thermal expansion, excessive localized heating can lead to cracks or glaze peeling.

Therefore, the physical properties of tiles pose challenges to the application of industrial wide belt sanders. Without considering professional abrasive belt materials, pressure control, and speed matching, directly grinding tiles with an industrial wide belt sander is likely to result in surface damage or premature equipment wear.

Is grinding tiles with an industrial wide belt sander feasible? —Analysis

To address the question "Can an industrial wide belt sander grind tiles?", an analysis is needed from three dimensions: equipment capability, abrasive belt material selection, and processing technology.

1. Equipment Capability Analysis

The main advantages of industrial wide belt sanders lie in large-area continuous grinding and uniform pressure control. If the equipment parameters allow for low-speed operation, adjustable belt tension, and precise pressure control, then theoretically, it's possible to attempt grinding the surface of tiles. However, excessive equipment power, excessively wide belt width, or high-speed operation may cause tile cracking. Therefore, preliminary grinding of tiles is only possible when the equipment has adjustable pressure, variable speed, and wide belt adaptability.

2. Belt Material Selection

Tile surfaces have high hardness, requiring the use of diamond or ceramic belts instead of ordinary sandpaper. Specific requirements are as follows:

• Diamond belts: High hardness and strong wear resistance, suitable for light grinding of high-hardness tile surfaces such as polished tiles and microcrystalline stone.

• Ceramic belts: Suitable for through-body tile surfaces, high temperature resistant, and less prone to edge chipping, but with low removal efficiency.

• Belt grit selection: Coarse-grained belts are prone to cracking; medium to fine grit (e.g., 200# to 800#) should be selected to balance grinding efficiency and safety.

3. Sanding Process Control

Even with a professional sanding belt, an industrial wide belt sander requires strict process control:

• Speed Control: The sanding belt speed should be lower than standard wood or metal sanding speeds, typically between 2000 and 4000 revolutions per minute, to avoid thermal cracking.

• Pressure Adjustment: The pressure applied to the tile surface must be even and moderate. Air pressure control or a spring-loaded system can be used to avoid excessive localized pressure.

• Multiple Light Sanding Sessions: It is not recommended to remove large amounts of material at once. Multiple light sanding sessions are preferable, removing very small amounts each time to ensure surface integrity.

• Cooling and Dust Removal: The heat generated by friction needs to be dissipated promptly. Temperature can be controlled through water spraying or air cooling. Simultaneously, dust removal equipment ensures that sanding belt residue does not affect surface quality.

In summary, while an industrial wide belt sander can theoretically sand tiles, it requires strict matching of the sanding belt material, control of speed and pressure, and the use of cooling and multiple light sanding sessions. Improper use can easily lead to tile cracking, edge chipping, or severe sanding belt wear.

Industrial Wide Belt Sander VS. Tile-Specific Equipment

To better understand the differences between industrial wide belt sanders and tile processing equipment, we can make the following comparison:

Characteristics | Industrial Wide Belt Sander | Tile Grinding Machine |

| Design Applications | Wood, Boards, Metals | High-hardness ceramics and stone |

| Grinding Media | Abrasive Belts (Alumina, Silicon Carbide) | Diamond grinding head or diamond wheel |

| Surface Pressure | Adjustable, but high-lifting | Precise and controllable, suitable for brittle materials |

| Workpiece Support | Feed Table | Shock-resistant support to prevent breakage |

| Machining Results | Flattening and Polishing Board Surfaces | Smoothing, deburring, and polishing glaze |

| Risks | Prone to Damaging Brittle Materials | Low risk, intact surface |

The comparison table shows that industrial wide belt sanders lag significantly behind tile-specific grinding machines in terms of hardness, vibration control, and processing precision. Therefore, in professional processing environments, tiles are typically not surface-treated using industrial wide belt sanders.

Operating Precautions for Grinding Tiles with an Industrial Wide Belt Sander

To safely and efficiently use an industrial wide belt sander to grind tiles, operators must follow these precautions:

• Equipment Setup: Before grinding, a comprehensive inspection of the equipment is necessary, including belt wear, tension, speed, and pressure adjustment.

• Belt Selection: Select diamond or ceramic belts according to the type of tile; avoid using ordinary belts directly.

• Safety Precautions: Wear protective eyewear, dust masks, and gloves to prevent injury from dust or debris generated during friction.

• Surface Inspection: After each light grinding session, check the tile surface for cracks or chipping, and adjust the pressure and belt grit accordingly.

• Environmental Conditions: Maintain moderate humidity in the working environment. If necessary, use cooling water spray to control surface temperature and reduce thermal stress.

• Multiple Grinding Steps: Avoid deep grinding in one go. Use a multiple light grinding strategy to ensure a smooth and intact tile surface.

Strictly adhering to the above operating procedures can, to a certain extent, ensure the controllable grinding effect of the industrial wide belt sander on tiles, while reducing breakage rate and belt wear.

"Can an industrial wide belt sander grind tiles?"

—The following conclusions can be drawn:

1. Feasibility: Not recommended. Although an industrial wide belt sander can theoretically grind tiles, it requires strict matching of belt material, speed, and pressure, and the use of multiple light grinding steps and cooling.

2. Critical Selection of Belt: Diamond belts and ceramic belts are essential for grinding tiles; ordinary sandpaper belts are not suitable.

3. Operational Risks: Improper operation with an industrial wide belt sander can easily cause tile cracking, edge chipping, or rapid belt wear. Therefore, operators must possess professional skills.

4. Balancing Efficiency and Safety: Compared to wood or metal surfaces, tile polishing demands higher levels of equipment control, requiring a balance between efficiency and safety.

How does XMF Machinery handle quotes and pricing?

XMF Machinery provides transparent and competitive pricing for all our coating equipment. Buyers can request detailed quotes from our sales team to compare costs and find the best purchasing solution. As a factory and manufacturer, we ensure that our prices remain low while delivering high-quality products. Wholesale purchasing and factory promotions make it easier to buy at low prices, and discounts are available for bulk orders. Our company guarantees clear communication about pricing so every buyer knows exactly what they are paying for, whether it's a customized machine or standard supply.