In modern manufacturing, surface treatment processes are not only crucial for enhancing a product's appearance but also directly impact its durability, corrosion resistance, functionality, and market value. Among numerous surface treatment technologies, "industrial spray painting," as a highly efficient, adaptable, and consistent coating method, is widely used for surface treatment of materials such as metal, plastic, wood, glass, and ceramics.

The increasing popularity and advancement of automatic spraying machines are a significant driving force behind the standardization, scale, and high-quality development of industrial spray painting.

What is industrial spray painting?

Industrial spray painting is a coating process in which specialized equipment sprays a uniform mist of paint onto a surface, creating a protective or decorative film. This process, unlike manual painting, emphasizes efficiency, precision, and consistency. It is widely used for surface treatment of various industrial products, such as automotive exteriors, mechanical parts, household appliances, building structures, and furniture panels.

Basic Characteristics of Industrial Spray Painting:

• Uses spray equipment (especially automatic spraying machines)

• Paint is atomized and sprayed in an aerosol state

• Forms a uniform, continuous paint film

• Suitable for mass production and automated production lines

• Can apply a variety of paints (solvent-based, water-based, powder, UV, etc.)

The core advantages of industrial spray painting lie in its high controllability, uniform coating, and production efficiency significantly superior to traditional manual methods. It is an extremely important process in modern industrial production.

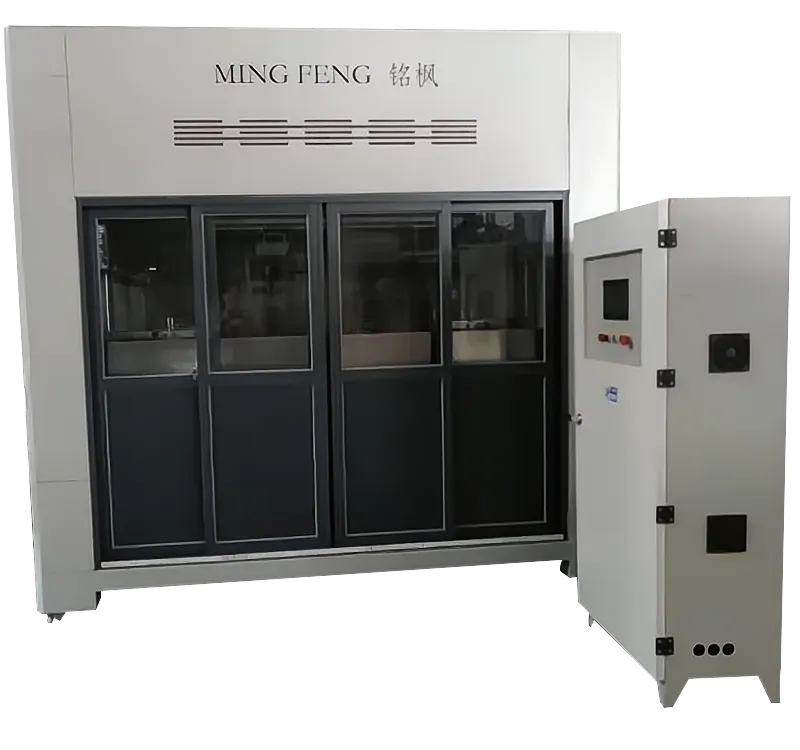

Automatic Spraying Machine: The Core Equipment of Industrial Spray Painting

1. What is an Automatic Spraying Machine?

Automatic spraying machines are specialized equipment that uses a programmable, automated control system to drive a spray gun or nozzle, precisely applying paint. Compared to manual spraying, automatic spraying machines can significantly improve spraying speed, coating consistency, material utilization, and operational safety.

Automatic spraying machines are widely used in industrial spray painting and are key equipment for achieving standardized, automated, and mass production of spray painting.

2. Main Functions of an Automatic Spraying Machine

• Automatic identification of spray targets (in conjunction with a vision recognition system)

• Control of spray angle, speed, path, and spray gun pressure

• Multi-axis linkage enables spraying of three-dimensional surfaces or complex shapes

• Integration with a conveyor system for continuous operation

• Interchangeable nozzles to accommodate paints of varying viscosities

3. Equipment Components of an Automatic Spraying Machine

A standard industrial automatic spraying machine system typically includes:

• Spraying control system (PLC/servo drive/human-machine interface)

• Spray gun system (rotating cup, pneumatic, electrostatic, etc.)

• Paint feed system (pump/piping/pressure regulator)

• Motion control platform (slide rails/multi-axis robot/lifting device)

• Ventilation and exhaust system (explosion-proof fan, filter)

• Auxiliary systems (preheating, dust removal, curing, etc.)

Automatic spraying machines can be customized to meet specific application requirements, adapting to workpieces of varying shapes and materials, and integrated with upstream and downstream equipment (such as polishing, curing, and assembly) to form an integrated coating production line.

What is the industrial spray painting process?

Industrial spray painting is more than just applying paint; it involves a sophisticated process, with the automatic spraying machine being the primary equipment.

Process Overview:

1. Surface Pretreatment

• Degreasing, rust removal, dust removal, drying, etc.

• Ensure paint film adhesion and durability

2. Primer Application (performed by an automatic spraying machine)

• Enhance topcoat adhesion and seal substrate pores

3. Drying or Curing

• Use natural drying, hot air drying, or UV curing methods

4. Flooding/Intermediate Sanding (Optional)

• Improve flatness and conceal base layer imperfections

5. Topcoat Application (performed by an automatic spraying machine)

• Achieve final color, gloss, and protective effect

6. Final Curing

• Meet paint film performance standards, such as scratch and chemical resistance

7. Quality Inspection and Packaging

• Check paint film thickness, uniformity, adhesion, etc.

Role of the Automatic Spraying Machine in the Process:

• Replaces manual spraying steps

• Precisely controls spray volume and path

• Improves spray consistency and reduces human error

• Saves paint and reduces waste

• Avoiding blind spots and coating buildup

What are the technical categories for industrial spray painting?

Industrial spray painting can be categorized by spraying method, equipment principle, and coating type. Different technical routes are suitable for different products and process objectives.

1. Classification by Spraying Method

• Air Spraying: A traditional method with excellent paint atomization, suitable for fine-grained coating.

• Air-Assisted Airless Spraying: High coating efficiency, commonly used for large-area coating.

• Electrostatic Spraying: Improves paint utilization through the principle of electric field adsorption.

• Rotary Bell Spraying: High-speed rotary atomization, suitable for automated and high-end coating.

• High-Pressure Airless Spraying: Utilizes high-pressure liquid to create a mist, suitable for heavy-duty anti-corrosion coating.

2. Classification by Equipment Structure

• Track-Mounted Automatic Spraying Machine: Stationary spray gun, mobile workpiece.

• Reciprocating Spraying Machine: The spray gun moves back and forth, suitable for flat surfaces or regular objects.

• Six-Axis Spraying Robot: Capable of coating complex three-dimensional shapes, flexible programming.

• Multi-Station Rotary Table Automatic Spraying Machine: Suitable for efficient batch processing of small parts.

3. Classification by Coating Type

• Solvent-based spray painting: A traditional paint system with high volatility.

• Water-based paint spraying: Environmentally friendly, but requires high spray gun material.

• Powder spraying: For metal workpieces, requires heat curing.

• UV paint spraying: Rapid light curing, suitable for high-gloss finishes.

Each spraying method has its own unique advantages in terms of spraying effect, equipment requirements, paint adaptability, and application scenarios. The selection of an automatic spraying machine is precisely based on these differences.

What are the key technical indicators for industrial spray painting?

As a standardized process, industrial spray painting has a well-established quality evaluation system. The following are several key indicators:

1. Coating Thickness (μm): Generally controlled between 20 and 100 μm, depending on the intended application.

2. Adhesion Grade: The bond strength between the paint film and the substrate, commonly tested using the cross-hatch method.

3. Weatherability: Resistance to UV rays and humid and hot environments.

4. Gloss: Reflectivity, with controllable gloss, matte, and semi-matte finishes.

5. Coating Uniformity: Absence of defects such as ripples, scattering, accumulation, and pinholes.

6. Paint Mist Recovery Rate/Paint Utilization Rate: Impacts production costs and environmental performance.

Painting with an automated spraying machine allows for more precise control of these parameters, improving overall quality consistency.

Efficiency and Quality Advantages of Automatic Spraying Machines

Introducing automated spraying machines for industrial painting offers significant advantages over manual methods:

Comparison Items | Manual spray painting | Automatic spraying machine for painting |

| Coating Consistency | Relies on manual experience | Program-controlled, minimal error |

| Material Waste | Severe paint mist dispersion | High spraying precision, comprehensive recovery system |

| Work Efficiency | Dozens of pieces per hour | Hundreds or even thousands of pieces per hour |

| Safety and Environmental Protection | Workers exposed to paint mist | Enclosed spray booth for excellent dust control |

| Maintenance Costs | Simple operation and low maintenance | Complicated equipment but lower long-term costs |

In the context of modern industry's demand for high efficiency, high quality, and low energy consumption, automated spraying machines have undoubtedly become the mainstream choice for industrial painting.

What are the common applications of industrial spray painting?

While industrial spray painting can be used on a wide variety of materials, the following industries represent typical applications:

1. Metal Manufacturing (automotive parts, steel structures, metal furniture)

2. Home Appliances (refrigerator panels, washing machine housings, air conditioner radiators)

3. Woodworking (furniture panels, doors, flooring, decorative panels)

4. Plastics (automotive interiors, household goods housings)

5. Glass and Ceramic Products (decorative glass, sanitary ware)

Automated spraying machines play a vital role in each of these applications, not only improving spraying efficiency but also significantly enhancing product consistency and appearance.

Can XMF Machinery machines be integrated into existing production lines?

Yes, our coating machines are designed with flexibility to smoothly integrate into existing production workflows. Whether upgrading or expanding your manufacturing setup, we provide customized solutions and installation support, ensuring seamless integration and improving overall production efficiency at competitive factory prices.